Application of Linear Scales in Gantry Machining Center

In the fiercely competitive manufacturing sector, precision is the decisive factor in determining equipment value.

As a manufacturer of gantry machining centers, we have been continuously exploring ways to enhance the machining accuracy and stability of our machines. The linear scale, as a core component for high-precision measurement, serves as the technical foundation for achieving these goals.

This article provides a comprehensive analysis of the application of linear scales in gantry machining centers and their profound impact on actual machining processes.

Working principle and structural composition of the linear scale

A grating scale is a measurement feedback device operating on the principle of photoelectric conversion. It converts mechanical displacement into digital signals, enabling precise detection of machine tool movement components. Mounted directly on the moving parts of the machine tool, it monitors displacement changes in real time, effectively equipping the machine with a pair of "sharp eyes".

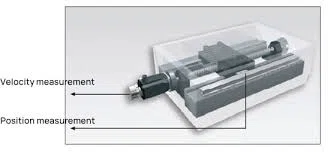

The fundamental structure of a linear scale comprises two primary components: the scale grating and the grating reading head. The scale grating is typically mounted on a fixed reference component of the equipment (e.g., a machine tool bed), featuring periodic parallel lines (grating lines) arranged at uniform intervals. The reading head, installed on a movable component (e.g., a worktable), contains internal components such as a light source, optical system, reference grating, and photoelectric detector.

The working principle of a grating ruler is based on Moire fringe technology. When the line patterns on the indicator grating and the scale grating overlap at a slight angle, interference and diffraction of light create alternating light and dark Moire fringes. As the scale grating moves one grating pitch, the Moire fringes shift by one fringe spacing. This optical magnification effect enables precise measurement of minute displacements.

Moire fringes have three key characteristics: magnification (enlarging small displacements by hundreds of times), averaging effect (eliminating individual engraved line errors), and direction correspondence (the movement direction is perpendicular to the fringe movement direction). These characteristics enable the grating scale to achieve high-precision measurement.

Compared to traditional rotary encoders, the key advantage of linear scales lies in their direct measurement capability. While encoders can only detect the number of motor rotations (an indirect measurement method) and cannot identify errors caused by screw rod wear, clearance, or thermal deformation, linear scales directly monitor the actual positional changes of the worktable. This precision measurement remains unaffected by any errors in the transmission chain.

Key applications of linear scale in gantry machining centers

Due to their large structure and long transmission chain, gantry machining centers face unique precision challenges. The application of grating scale is particularly important in these equipment, which is mainly reflected in the following aspects:

1. Solve the problem of long-distance positioning accuracy

Long gantry machine tools feature extended drive chains that are prone to error accumulation. The grating scale effectively addresses the "long-distance drift prevention" issue by directly measuring worktable displacement. Its "long-arm jurisdiction" function ensures precise positioning and stable machining performance during prolonged continuous operation or extensive motion ranges.

Practical applications demonstrate that a heavy-duty gantry CNC boring and milling machine with an X-axis measurement range of 64 meters achieved 0.025mm/m positioning accuracy and 0.015mm repeatability by installing two 65-meter-long linear scales. Such precision levels are unimaginable for traditional large-scale machine tools without linear scales.

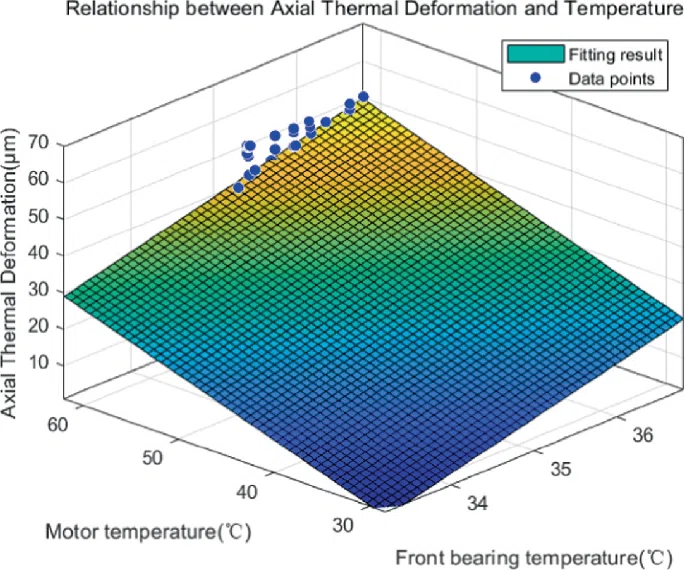

2. Compensation for errors caused by thermal deformation

During continuous machining of large machine tools, the lead screw and bed may deform due to thermal effects. The real-time correction function of the linear scale can quickly adjust when the lead screw elongates due to heating after half an hour of machining, ensuring machining accuracy is not affected. This real-time compensation capability is particularly critical for maintaining stability during long-term machining.

3. Improve repeatability

For components requiring repeated machining, linear guides can significantly improve the repeatability of machine tool positioning. Case studies demonstrate that when an aging machining center was equipped with linear guides, its repeatability accuracy improved from ±8μm to ±2μm, resulting in notable enhancements in machining quality. This improvement proves particularly crucial for precision mold manufacturing and mass production processes.

4. Realize the true sense of full closed-loop control

As the core component of a CNC machine's closed-loop control system, the linear encoder directly measures the worktable's position and feeds this data back to the CNC system. The system then compares this information with the target position and makes real-time adjustments to correct deviations. This control method effectively eliminates the impact of various error factors in the transmission chain on machining accuracy.

The actual effect of the linear scale on machining accuracy: data and case

In order to more intuitively show the influence of the linear scale on the processing quality, we illustrate its actual effect through specific data and cases:

1. Quantitative comparison of precision improvement

Processing metrics | No grid ruler | A linear scale is available | Increase amount |

positioning accuracy | ±0.01mm | ±0.002mm | Increase by 5 times |

Duplicate positioning accuracy | ±8μm | ±2μm | Increase by 4 times |

long term stability | Decrease with the extension of processing time | Stable for 8 consecutive hours | markedly improve |

Reverse gap compensation | Depends on regular manual adjustments | Real-time automatic compensation | High degree of automation |

Table: Comparison of the improvement effect of the linear scale on machining accuracy

2. Improvement of actual machining quality

In practical machining applications, the installation of a linear scale significantly enhances dimensional consistency of workpieces, particularly for large-scale components and precision parts. In precision mold manufacturing, this technology enables more accurate fit clearance, thereby substantially extending mold durability and improving the quality of injection-molded products.

In the field of aviation part machining, the grating scale ensures high-precision machining of complex surfaces and precision structures, meeting the stringent quality requirements of the aviation industry. In the machining of large structural components, the grating scale effectively controls long-distance cumulative errors, ensuring the assembly accuracy and operational performance of large equipment.

3. Improved processing efficiency

The grating scale not only improves machining accuracy, but also significantly improves machining efficiency. Due to the reduction of trial cutting measurement and adjustment time, the actual cutting time ratio of the machine tool is greatly increased. At the same time, the high-precision positioning control reduces the rework rate and scrap rate, further reducing the production cost.

Guide to Selecting a Grating Scale

Proper selection is essential for optimal performance of the linear scale. The key considerations for selecting a linear scale are as follows:

1. Precision and Resolution Selection

The accuracy class of the linear scale should be selected according to the specific processing requirements. For general metal cutting, ±0.01mm accuracy may be sufficient; but for precision molds, aviation parts and other applications, ±0.005mm or even higher accuracy level is required.

Resolution selection also requires careful consideration. Industry experience suggests choosing a linear scale with three times the required precision. For example, if the target accuracy is ±1μm, a 0.3μm resolution linear scale should be selected. This "over-configuration" ensures the measurement system itself does not become a precision bottleneck.

2. Type and Structure Selection

Depending on their application environments, grating scales are categorized into two types: open and closed. Open grating scales are high-precision devices that produce sine wave outputs, primarily used for digital upgrades of precision instruments. In contrast, closed grating scales are mainly employed for digital transformations of standard machine tools and instruments, with square wave outputs.

Grating scales are categorized by size into two types: wide and narrow. The narrow type can extend up to 1 meter, while the wide type is available in lengths up to 30 meters. For large gantry machining centers, wide-type grating scales are typically preferred to meet the requirements of long-stroke measurements.

3. Length and Signal Type Selection

The measurement range of the linear scale can be from 50mm to 30m, or even longer (such as 60m), covering almost all the travel of metal cutting machine tools. When selecting the model, it is advisable to choose a linear scale that exceeds the machining size of the machine tool by about 100mm, so as to leave a margin.

Signal type is also a critical consideration during selection. Common types include 5V square wave, sine wave, and high-interference-resistant positive-negative code signal scales specifically designed for spark machines. The appropriate signal type should be selected based on the interface requirements of the CNC system.

4. System Compatibility Considerations

When selecting a system, verify if the CNC supports full closed-loop control and can smoothly integrate the grating scale signal. Some older systems may lack this capability, and installing the grating scale may cause servo system oscillations, compromising machine stability.

Key points for installation and debugging of the linear scale

The installation quality of the linear scale directly affects its service performance and service life. The following are the key installation points:

1. Installation Base Surface Treatment and Requirements

When installing a linear scale sensor, avoid mounting it directly on a rough or uneven machine tool surface. Ensure the installation base is parallel to the guide rail movement direction with a tolerance of 0.1mm/1000mm. If this requirement cannot be met, a custom-made linear scale base must be designed and fabricated.

The base must meet the following requirements: its length should match the grating ruler body (ideally extending approximately 50mm beyond the ruler); it must be machined through milling and grinding processes to ensure planar parallelism within 0.1mm/1000mm; the height difference between the reading head base and the ruler body base should not exceed ±0.2mm.

2. Installation Position Selection and Abbe Error Control

To minimize Abbe error, the linear scale should be positioned as close as possible to the moving components. This principle mirrors how a ruler's accuracy improves when it's pressed tightly against the surface. Typically, the main scale is mounted on the machine tool's worktable (sliding plate) and moves with the tool's feed, while the measuring head remains fixed on the bed. The measuring head should ideally be positioned below the main scale for optimal measurement accuracy.

The installation method must consider the direction of chip, cutting fluid, and oil splashing. If the reading head must be installed upward due to installation position restrictions, an auxiliary sealing device must be added.

3. Accurate installation of the main scale and reading head

When installing the main scale, first secure it preliminarily with M4 screws. Then, use a micrometer to measure the parallelism between the main scale plane and the machine tool's guide rail movement direction. After adjusting to meet the requirement of 0.1mm/1000mm, fully tighten the screws.

For long rulers exceeding 1.5 meters, installing only the two ends is insufficient. Additional supports must be added throughout the main ruler body to prevent sagging in the middle. After installation, the gap between the reading head and the ruler body should be maintained at approximately 1~1.5mm, with parallelism kept within 0.1mm.

4. Key debugging steps and accuracy verification

After installation, laser interferometer compensation must be performed. Do not expect the grating scale to be ready to use. Through professional debugging, the positioning error of the machine tool can be accurately detected, providing a basis for the precision adjustment and error compensation of the machine tool.

After debugging, accuracy verification is required: select a reference position on the machine tool, move the worktable back and forth to that position, and the digital meter reading should be the same; or use a micrometer to compare the measurement, to ensure that the measurement value of the grating scale is consistent with the actual displacement.

Maintenance and Fault Prevention of Grating Scale

In order to ensure the long-term stable operation of the grating scale, a scientific maintenance system should be established:

1. Daily protective measures

The linear scale is highly sensitive to oil and dust. A protective cover must be installed, and chips and oil splashed on the scale must be cleaned promptly. Any foreign matter must be strictly prevented from entering the sensor housing.

To extend the service life of the dust seal strip, a thin layer of silicone oil can be evenly applied on the seal strip, but do not let it splash on the glass grating engraving surface. This simple maintenance measure can significantly extend the service life of the seal strip.

2. Periodic cleaning and inspection

Clean and wipe the grating scale surface and the indicator grating surface regularly with a 50% ethanol mixture to keep the glass grating surface clean. The cleaning cycle should be determined according to the use environment. Generally, it is recommended to carry out a thorough cleaning every 3-6 months.

Check all installation screws for looseness to ensure stability. For high-speed machines, verify the limit device is intact to prevent the measuring head from colliding with the main scale's ends and causing damage.

3. Common Fault Diagnosis and Prevention

The most common failure in grating scale usage is signal issues caused by contamination of the reading head, which manifests as unstable position display or sudden jumps. Preventive measures include ensuring proper sealing and regular cleaning of the reading head.

Another common issue is signal transmission failure, which may be caused by cable wear or loose connectors. Check the cable status regularly and avoid excessive bending or pulling. Unstable power voltage may also cause abnormal operation, so ensure stable power supply.

Development trend and prospect of grating scale technology

With the increasing requirements of precision in manufacturing, the technology of grating scale is also progressing:

1. Technology development direction

The current grating scale technology is developing towards higher accuracy, stronger anti-interference ability and longer service life. In terms of accuracy, the resolution of advanced grating scale has reached the nanometer level, meeting the needs of semiconductor manufacturing and precision engineering.

In signal processing, new filtering algorithms and subdivision techniques are emerging to improve signal quality and measurement stability. At the same time, new interfaces and communication protocols enable grating scales to be better integrated into intelligent manufacturing systems.

2. Comparison of domestic and foreign technologies

Currently, renowned international brands such as Germany's HEIDENHAIN lead in the field of grating scale technology. HEIDENHAIN's high-end grating scales achieve a resolution of 1 nanometer and precision of ±0.1 micrometer, playing a crucial role in precision-critical industries like semiconductor manufacturing and aerospace.

China's grating scale industry has made remarkable progress through years of development. A prime example is the 30-meter ultra-long-range enclosed grating scale developed by Changchun Yuheng Optics Co., Ltd., which meets the measurement requirements for large-scale equipment manufacturing and aerospace testing. However, domestic products still lag behind international top-tier standards in terms of extreme precision and adaptability to special environments.

3. Future application prospects

With the advancement of intelligent manufacturing, grating scales will play a more important role in digital factories. Combined with Internet of Things technology, grating scales can not only provide position feedback, but also collect equipment running status data to support predictive maintenance.

In emerging industries, such as new energy vehicles, aerospace and medical devices, the demand for high-precision machining will continue to grow, which will further promote the development of grating scale technology and the expansion of its application scope.

The application of linear scale in gantry machining center is a key measure to improve machining accuracy. By directly measuring the displacement of the workbench and real-time compensation of errors, linear scale can improve machining accuracy several times, which is especially suitable for high-precision machining, upgrading old equipment and preventing drift of large machine tools.

However, a linear scale is not a panacea. If the mechanical foundation is weak (such as severe wear on the guide rails or insufficient spindle rigidity), the linear scale may not function effectively. Before installing a linear scale, assess the machine's mechanical condition and, if necessary, perform major repairs or upgrades to the mechanical components.

With the increasing requirements of precision in the manufacturing industry, the technology of grating scale is also making continuous progress. In the future, we have reason to believe that the grating scale will play a more important role in the field of intelligent manufacturing, helping manufacturers to achieve higher precision and higher quality processing goals.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763