Common faults in 5-Axis Machining Center processing: Fast tool wear, rough surface? Product Adaptation and Process Adjustment Guidelines

5-Axis Machining Center, as core equipment in the field of precision manufacturing, are widely used in high-precision processing scenarios such as aerospace, medical implants, and automotive special-shaped parts. However, the frequent faults of "rapid tool wear" and "rough surface" during their operation often lead to increased production costs, extended production cycles, and even batch product scrapping.

To address the core issue of "common faults in 5-Axis Machining Center processing: rapid tool wear and rough surface", it is necessary to first clarify the essence of the fault - 90% of such problems do not stem from equipment performance defects, but are the result of the combined effect of "product mismatch" and "inappropriate process parameters". A mismatch between the hardness of the cutting tool material and that of the workpiece can lead to insufficient red hardness of the cutting tool, reducing its service life by 70% sharply. Substandard precision of auxiliary tools can cause fluctuations in cutting force and accelerate local wear at the tool tip. However, process issues such as excessively high feed rates and lack of cooling and lubrication will directly lead to coarsening of the cutting marks and the appearance of "tool biting marks" on the surface, causing the roughness to exceed the standard.

This article will provide multi-dimensional practical support: it not only includes tool selection comparison tables by material and the "golden combination" of cutting parameters that can be directly applied, but also comes with a list of equipment maintenance cycles. Furthermore, through the fault optimization case of a certain automotive mold factory, the actual achievements of "extending the tool life from 8 hours to 45 hours" and "reducing the scrap rate from 10% to 2%" will be quantitatively presented, enabling technicians, process engineers and production managers to quickly compare with their own production scenarios and find the path to solve the faults.

The "Cost Trap" of Five-Axis Machining - Are You Paying for Faults?

Let's first take a look at two real cases to see how terrifying these "hidden losses" are:

Case 1: The "Tool Nightmare" of an Aviation Parts Factory

A certain factory processes titanium alloy engine mounts and uses high-speed steel cutting tools. As a result, the tools have to be changed on average every two days. When calculated, the monthly cost of tool procurement exceeds $4,500. What's even more troublesome is that the machine tool must be shut down when changing tools. The daily downtime alone accounts for 15%. The original production capacity of 50 pieces has been reduced to 42 pieces.

Case 2: The "Scrapping Crisis" of Medical Equipment Factories

When manufacturing orthopedic implants (such as artificial joints), the surface roughness Ra value is required to be ≤0.8μm. However, after actual processing, the Ra value of 12% of the parts soared above 1.2μm and could only be scrapped. At a cost of $60 per part, the monthly rework loss exceeds $7,200, and it also delays the customer's delivery date.

In fact, for 90% of such problems, the root cause is not the "poor performance" of the 5-Axis Machining Center, but two core misunderstandings: "incorrect product matching" (such as using ordinary tools to process high-hardness materials) and "incorrect setting of process parameters" (such as too fast cutting speed).

Next, we will guide you step by step to identify and solve problems.

Five core reasons for rapid tool wear and rough surface

Before solving the problem, it is necessary to first figure out "where the problem lies". The following reasons can be checked one by one against the situation in your own workshop.

1. Fast tool wear? Most likely, these four pitfalls were not avoided

(1) Material mismatch: "Using a kitchen knife to cut steel plates", how could the knife not be damaged?

The most common mistake is that "the hardness of the cutting tool cannot keep up with that of the workpiece." For instance, when using high-speed steel cutting tools (suitable for processing soft steel and aluminum) to cut high-temperature alloys with a hardness of HRC35 or above, it is like using a regular kitchen knife to chop steel plates - high-speed steel will "soften" at high temperatures (professionally known as "insufficient red hardness"), and a tool that could last for 20 hours will break within 6 hours, with its lifespan directly reduced by 70%.

Note: Before choosing a cutting tool, first check the hardness of the workpiece (measured with a hardness tester), and then select a tool with a hardness 20-30HRC higher than that of the workpiece.

(2) Parameter overload: "Let the car run at high speed", the tip of the knife is directly "burned"

Some masters, in order to increase production capacity, deliberately raise the cutting speed - for instance, when processing titanium alloys with hard alloy tools, they increase the speed from the recommended 50m/min to 60m/min. So, what was the result? The temperature at the tip of the knife will instantly exceed 800℃, just like roasting the blade over fire. The cutting edge will quickly crack and become completely unusable.

(3) Path defect: "Taking a longer route to work", the tool is wasted

Many people use the "three-axis thinking" to write five-axis programs: for instance, when processing a multi-faceted part, they first cut the front side and then adjust the Angle to cut the side side. The number of idle tool passes in the middle is high, and "repeated cutting" (cutting the same position twice) may also occur. In this way, the cutting tools do not exert effort in their "proper work", but instead bear additional loads during idle running, increasing ineffective wear by 30%.

(4) Insufficient precision of auxiliary tools: "The handle wobbles", and the force on the tip of the knife is uneven

No matter how good the cutting tool is, if the precision of the handle is poor, it is all in vain. For instance, if a common spring tool holder or an HSK tool holder has a "runout" exceeding 0.002mm (approximately 1/35 of the diameter of a human hair), the tool will slightly shake during processing, the radial cutting force will fluctuate greatly, and the local wear of the tool tip will be particularly rapid - just like cutting paper with a wobbling pair of scissors, the cutting edge will soon become blunt.

2. Rough surface? Compare these four points of question

(1) Incorrect feed strategy: "Moving too fast, leaving too many traces"

The feed rate(the distance the tool moves per minute) is not the higher the better. If the feed rate exceeds 0.2mm/rev (feed per revolution), the "cutting marks" left by the tool on the workpiece surface will become coarser. For instance, if the target is Ra0.8μm, it will actually become Ra1.2μm, directly exceeding the standard by 50%.

Simply put: It's like grinding wood with sandpaper. If you grind it too fast, it will leave obvious scratches; if you grind it a little slower, it will be smoother instead.

(2) Deterioration of the tool condition: "If the knife is blunt, how can it cut smoothly?"

After long-term use, the rear face (the side of the tool) of the cutting tool will wear out. When the wear width exceeds 0.2mm, "gnawing marks" will appear on the processed surface - just like peeling an apple with a blunt knife, the peel will become uneven and the roughness will double directly.

Note: Before starting work every day, take a magnifying glass to check the rear face of the tool. If the wear exceeds 0.2mm, replace it immediately.

(3) Lack of cooling and lubrication: "Dry cutting is like 'grinding tofu', sticky and rough.

When processing aluminum alloy and stainless steel, if cooling and lubrication are not added, the cutting tool will "stick together" with the workpiece (professionally called "stuck tool"). For instance, when processing aluminum alloy, aluminum shavings will stick to the tip of the tool. When the next cut is made, the adhered aluminum shavings will leave scratches on the surface of the workpiece, with the Ra value exceeding the tolerance by 30%.

Nowadays, many factories use "micro-lubrication (MQL)", which involves spraying a small amount of oil mist into the cutting area. It is both environmentally friendly and can prevent the tool from sticking, and its effect is much better than dry cutting.

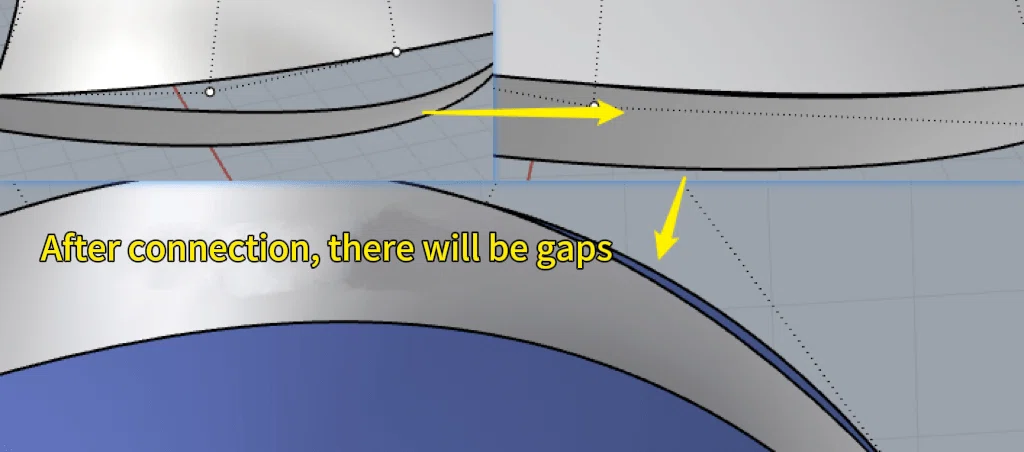

(4) Deviation in linkage accuracy: "The axes are not aligned, resulting in 'steps' being cut out."

5-Axis Machining Center process curved surfaces through the linkage of "X/Y/Z axes + two rotary axes". If the "clearance" of the rotating shaft exceeds 0.003mm, there will be slight misalignment between the shafts during processing, and "tool connection steps" will appear at the connection points of the curved surfaces - just like when two wooden boards are joined together and not aligned, there will be a small protrusion. Subsequently, additional polishing is required, which is both labor-intensive and time-consuming.

Product Compatibility: Select the right "cutting tools + accessories" to reduce malfunctions from the source

The first step to solving a problem is to "choose the right tool". The following guide can be directly referred to your own processing requirements.

1.Five-axis Special Tool Selection Table

Processing materials | Recommended tool types | Core parameter requirements (How to read?) | The effect of enhancing tool life | Applicable scenarios |

Common steel (≤HRC30) | High-speed steel M2 (TiN coating) | Hardness: HRC63-66 (refer to the tool manual); The flexural strength is ≥2800MPa | It can last 40% longer than uncoated tools | Small and medium batch structural components (such as gears and shafts) |

Titanium alloy/superalloy | Hard alloy (AlTiN coating) | Red hardness ≥600℃ (does not soften at high temperatures); High-temperature resistant to oxidation | It was extended from 20 hours to 80 hours | Aerospace precision components (such as engine mounts) |

Aluminum alloy | Diamond coated cutting tools | Surface finish Ra≤0.02μm; Anti-sticking knife design | Eliminate tool sticking and achieve 100% roughness compliance | Automotive lightweight parts (such as aluminum housings) |

【 Selection Tips 】

When purchasing cutting tools, give priority to manufacturers that offer "free trial cutting" - take 1-2 pieces for trial processing first. If the effect is good, then buy in bulk to avoid waste.

The coating is very important: AlTiN coating is suitable for high-hardness materials, TiN coating is suitable for ordinary steel, and diamond coating is suitable for aluminum alloy. Do not mix them.

2. Avoiding Pitfalls in assistive Device Fitting: Don't make mistakes in choosing these 3 points

(1) Tool holder: Choose HSK tool holders for more stable precision

Stop using the ordinary spring knife handle! Give priority to choosing HK-A63 or HK-E50 tool holders (depending on the model of the machine tool spindle). The "runout" of these tool holders can be controlled within 0.001mm, which is much more stable than spring tool holders and can increase tool life by 25%.

When purchasing, make sure to ask clearly: "What is the runout of the knife handle?" It is qualified only if it is less than 0.001mm.

(2) Chucks: Heat shrinkable chucks are better than spring chucks

The chuck is the "component for fixing the tool". Choose a heat shrink chuck (clamping accuracy ≤0.003mm), and do not use an ER spring chuck (accuracy is prone to drop above 0.01mm). The heat shrink chuck fixes the tool by "heating and shrinking", without any gaps. During processing, it will not shake and can reduce the wear of the tool tip.

(3) Cooling system: High-pressure cooling is mandatory for high-hardness materials

When processing hard materials such as titanium alloys and die steel, a high-pressure cooling system must be installed - with a pressure of ≥70bar (approximately seven times the pressure of inflating a car tire) and a flow rate of ≥20L/min. High-pressure coolant can directly reach the cutting zone, carrying away heat and iron filings, reducing thermal wear of the cutting tool, and also making the surface smoother.

Process Adjustment: 3-step optimization to address wear and roughness issues

After choosing the right tools, the next step is to "adjust the process well". You can try these three steps at any time on your machine tool.

1.The "Golden Combination" of cutting parameters

Many masters adjust parameters based on "feeling", but in fact, different materials have fixed "golden parameters". Just follow the Settings and you'll be fine:

Processing materials | Tool type | Cutting speed (m/min) | Feed rate (mm/rev) | Depth of cut (mm) | Cooling requirements |

Common steel (≤HRC30) | High-speed steel M2 | 80-120. | 0.1-0.15 | 2 or less | Emulsion (concentration 5-8%) |

Titanium alloy | Hard alloy (AlTiN) | 30-50 | 0.05-0.1 | 1 or less | High-pressure cooling (70-100bar) |

Aluminum alloy | Diamond coated cutting tools | 300-500. | 0.15-0.2 | 3 or less | Micro-lubrication (spray oil at 10-30ml/h) |

【 Parameter Tips 】 :

Novices can start trying from the "lower limit", for example, set the cutting speed of titanium alloy at 30m/min first, and gradually increase it when the effect is good.

Never exceed the parameters at will just to catch up with the production capacity. For instance, if the speed of titanium alloy exceeds 50m/min, the cutting tools will wear out faster and even slower.

2. Five-axis Linkage Path optimization: 3 tips for cutting and Smoothness

(1) Replace linear cutting with cycloidal milling

When processing deep cavities and complex curved surfaces, instead of using the traditional "straight line back-and-forth cutting", switch to "cycloidal milling" - the tool cuts like "drawing circles", which can increase the material removal rate by 35% while reducing the tool load by 40%. For instance, when processing a cavity that is 5mm deep, the original cutting tool would be worn out after 15 hours, but now it can be used for up to 26 hours.

Most programming software (such as UG, Mastercam) has a "cycloidal milling" function, which can be directly invoked.

(2) When processing curved surfaces, "adjust the inclination Angle", do not force it with the tip of the tool

The advantage of five-axis is that it "can adjust angles"! When processing curved surfaces, set the tool's inclination Angle to 20°-45°, and cut with the "side edge" instead of directly cutting with the "tip". The tip of the knife is the most vulnerable part of the tool. The side edge has a larger area, wears out more slowly, and can also make the surface smoother - just like scraping paper with the side of a ruler, it is more uniform than scraping with the sharp corner.

(3) Set a "residual height" and do one less polishing

When programming, set the "residual height" to ≤0.005mm (which can be directly set in the software). The residual height is the "height difference between two adjacent cutting paths". The smaller the value, the smoother the surface, and subsequent polishing is basically not required, which can save 30% of the working hours.

Process Adjustment: 3-Step Optimization to Solve Tool Wear and Surface Roughness Issues

Once you've selected the right tool, the next step is optimizing the process. These 3 steps can be tested directly on your machining center.

1. The "Golden Combo" of Cutting Parameters

Many machinists adjust parameters based on “gut feeling,” but in reality, each material has recommended standard cutting parameters — just follow them:

| Material | Tool Type | Cutting Speed (m/min) | Feed Rate (mm/rev) | Depth of Cut (mm) | Cooling Requirement |

|---|---|---|---|---|---|

| General Steel (≤HRC30) | HSS M2 | 80–120 | 0.1–0.15 | ≤2 | Emulsion (5–8% concentration) |

| Titanium Alloy | Carbide (AlTiN-coated) | 30–50 | 0.05–0.1 | ≤1 | High-pressure cooling (70–100 bar) |

| Aluminum Alloy | Diamond-coated Tools | 300–500 | 0.15–0.2 | ≤3 | Minimum Quantity Lubrication (10–30 ml/h oil spray) |

Parameter Tips:

-

Beginners should start from the lower limit, e.g., set titanium cutting speed to 30 m/min first, then increase if results are stable.

-

Never randomly exceed parameters to boost output — for instance, running titanium at over 50 m/min will drastically shorten tool life, reducing efficiency instead of improving it.

2. 5-Axis Toolpath Optimization: 3 Tips to Save Tools and Improve Finish

(1) Use Trochoidal Milling Instead of Linear Cutting

When machining deep cavities or complex surfaces, avoid traditional "back-and-forth linear cuts". Replace them with trochoidal milling — where the tool moves in small circular paths. This increases material removal rate by 35% while reducing tool load by 40%.

For example, when machining a 5 mm deep cavity, tool life improved from 15 to 26 hours.

Most CAM software (like UG, Mastercam) includes trochoidal milling — just activate the function.

(2) Tilt the Tool Instead of Forcing the Tip on Surfaces

The advantage of 5-axis machining is angle control. When machining curved surfaces, set a tool tilt angle between 20°–45°, using the side cutting edge instead of the fragile tool tip.

Side edges have more contact area, wear slower, and produce smoother finishes — like using the side of a ruler to scrape paper instead of its sharp corner.

(3) Set Scallop Height to Minimize Polishing

In CAM programming, set scallop height to ≤0.005 mm. This is the vertical step between adjacent toolpaths.

Smaller scallop height = smoother finish = little to no polishing needed afterward, saving up to 30% of processing time.

3.Tool wear warning: 3 signals, it's time to change the tool

Don't wait until the tool is completely broken to replace it. Replace it immediately when these 3 signals appear to avoid batch scrapping

(1) Visual signal: The wear width of the rear face of the tool exceeds 0.2mm, or there is chipping at the tool tip (a small notch can be seen with a magnifying glass);

(2)Data signal: The machine tool load meter shows "The load suddenly increases by 15%" (for example, the load is usually 50% and suddenly rises to 65%), and the material of the workpiece remains unchanged.

(3)Batch signal: For every 50 parts processed, randomly inspect one to check the surface roughness - if the Ra value suddenly increases, it indicates that the tool is about to fail.

For instance, when processing titanium alloy parts, it is advisable to record "change the tool every 40 pieces processed", which can not only ensure quality but also avoid wasting the tools.

Equipment Maintenance: Do three things well to extend tool life and stabilize roughness

Many people overlook "equipment maintenance", but in fact, only when the machine tool is in good condition can the cutting tools and roughness be stable. For what to do every day, every week and every month, please refer to the following list

Daily must-do: 2-minute quick check

1. Measure the runout of the main shaft: Attach a dial indicator to the end face of the main shaft, rotate the main shaft, and the pointer should not swing more than 0.002mm (if it does, contact a maintenance person for adjustment).

2. Check the grease: Observe the oil level of the guide rail grease. If it is below the "minimum line", add (add the same type of grease, do not mix).

Weekly must-do: 1-hour calibration

1. Calibrate the rotating axis: Use a laser interferometer to measure the positioning accuracy of the five-axis rotating axis. The repeat positioning error should be ≤0.003mm (exceeding this limit will result in tool marks).

2. Check the cooling pressure: Turn on the high-pressure cooling and see if the pressure gauge shows 70-100bar (if the pressure is insufficient, clean the filter).

Monthly must-do: 2-hour maintenance

1. Clean the tool magazine: Wipe off the iron filings and oil stains in the tool magazine to prevent tool collisions when changing tools.

2. Lubricate the tool changing mechanism: Apply lubricating oil to the bearings and guide rails of the tool changing arm to reduce tool changing errors.

Note: Stick this list beside the machine tool. Whoever operates it should check it to avoid omissions.

Case: The "Cost Reduction Miracle" of a Certain Auto Mold Factory

Finally, let's take a look at a real optimization case to see how well these methods work after being implemented

Customer background: A certain automotive mold factory processes Cr12 mold steel (hardness HRC55) and produces automotive stamping dies.

Question

The cutting tool is made of common hard alloy, with a lifespan of only 8 hours and a monthly cutting tool cost of $2,300.

The surface roughness is Ra3.2μm, which does not meet the standard. Every month, 10% of the parts are scrapped, resulting in a loss of $4000.

Optimization plan

1. Product compatibility: Replace with AlCrN-coated cemented carbide tools (oxidation resistance temperature 1100℃) + HSK heat shrink chucks;

2. Process adjustment: Reduce the cutting speed from 150m/min to 80m/min, use cycloidal milling for the path, and operate at 70bar for high-pressure cooling.

3. Maintenance Enhancement: Measure the runout of the main shaft every day and calibrate the rotating shaft every week.

Improvement effect

The tool life has been extended from 8 hours to 45 hours, and the monthly tool cost has dropped from $2,300 to $450, saving $1,900.

The surface roughness has been reduced from Ra3.2μm to Ra0.8μm, the scrap rate has dropped from 10% to 2%, and the monthly loss is reduced by $3200.

A total of $5,000 was saved each month, and the optimization investment was recovered within six months.

FAQ

Q1: With a limited budget, can Chinese-made tools be used to solve the wear problem in five-axis machining?

A: Absolutely! In recent years, China has developed a mature technical system for manufacturing cutting tools in the field of precision machining. Many high-quality brands can offer cost-effective options for enterprises with limited budgets. For instance, Zhuzhou's "Golden Diamond" series, Shangao's "TP2501" model, and the MINNUO brand, which focuses on five-axis machining scenarios - the five-axis dedicated tool series it has launched includes Altin-coated cemented carbide tools suitable for common steel and aluminum alloys. By optimizing the adhesion of the coating and the edge strengthening process, When processing common steel (≤HRC30), its service life can reach over 90% of that of imported similar models. When processing aluminum alloys, it can effectively reduce the phenomenon of tool sticking, and the overall procurement cost is about 40% lower than that of imported tools.

Q2: When processing curved surface parts, how can we avoid the impact of "tool marks" on roughness?

A: Two tips: ① Set an "overlapping cutting zone" when programming - overlap two adjacent cutting paths by 0.5 to 1mm, making the connection smoother; ② Reduce the moving speed of the rotating shaft to 500mm/min. Don't go too fast. This will give the shaft sufficient response time and reduce misalignment.

Q3: Without dedicated five-axis programming software, how can parameters be temporarily optimized?

A: If UG or Mastercam is used, directly call the "Five-axis Machining Template" (provided by the software). If there is no template, temporarily adjust two parameters: ① Reduce the feed rate to 70% of the original; The allowance for finishing has been increased from 0.1mm to 0.3mm, which can temporarily improve the roughness and prevent scrapping.

Q4: Is the rapid wear of cutting tools related to the rigidity of machine tools?

A: Relevant! If the rigidity of the machine tool spindle is insufficient (for example, in an old machine tool, the radial runout of the spindle exceeds 0.003mm), it will "vibrate" during cutting and the tool wear will accelerate. In this case, do not force a large cutting depth. Reduce the cutting depth by 20%, for instance, if you originally cut 2mm and now cut 1.6mm, it can reduce chatter and extend the tool life.

Q5: When processing stainless steel, there is always "built-up edge" on the surface. How to solve it?

A: The built-up edge is caused by the stainless steel "sticking to the knife". There are two solutions: ① Cool with an emulsion, and adjust the concentration to 8-10% (not too dilute); ② Increase the feed rate to 0.12-0.15mm/rev to enable the chips to quickly detache from the tool tip and reduce sticking to the tool. After such treatment, the built-up edge will be reduced and the roughness can be increased by 30%.

Conclusion

Looking at the two core pain points of "fast tool wear and rough surface" in 5-Axis Machining Center processing, the solutions have never relied on "high-priced equipment replacement", but have returned to the essence of "precise matching" and "fine control" - from choosing tools based on the material and hardness of the workpiece to optimizing auxiliary tools according to the processing scenario From the scientific setting of cutting parameters to the regular maintenance of equipment, every step points to the core goal of "reducing costs, improving efficiency and ensuring accuracy".

For manufacturing enterprises that pursue efficient production, both high-quality products and scientific solutions are indispensable. As a brand dedicated to the field of precision machining, MINNUO's five-axis dedicated tool series, HSK high-precision tool holders and heat shrinkable chucks are all designed based on the concept of "scenario-based adaptation". For instance, MINNUO's Altin-coated tools have a red hardness of over 600℃, making them suitable for difficult-to-machine materials such as titanium alloys and high-temperature alloys. It can extend the tool life to 3 to 4 times that of traditional tools. When paired with the MINNUO HSC-A63 tool holder (runout ≤0.001mm), it can further reduce the fluctuation of cutting force and help stably control the surface roughness within Ra0.8μm.

From product adaptation to process implementation, MINNUO has always been guided by the principle of "solving customers' actual processing problems", providing enterprises with an integrated solution of "cutting tools + auxiliary tools + technical support", so that the "cost reduction and efficiency improvement" of five-axis machining no longer remains at the theoretical level, but is transformed into quantifiable production benefits.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763