Top 5 Global CNC Turning-Milling Center Manufacturers

For many professionals involved in high-precision manufacturing, selecting a reliable CNC turning-milling center is a big deal! Efficiency, precision, and stability are all essential, but with so many choices on the market, how do you know which one to choose?

DMG Mori, Haas, Mazak, Minnuo, and Tsugami are the top five leading global manufacturers of CNC turning-milling centers, each excelling in high-precision machining, intelligent solutions, and customized services.

Let’s dive into a detailed overview of these trustworthy brands!

1. DMG Mori – Leading the Way in Efficient Turning-Milling Processing

As a global leader in high-precision machine tool manufacturing, DMG Mori has service networks in 44 countries and multiple production bases, representing innovation, quality, and precision.

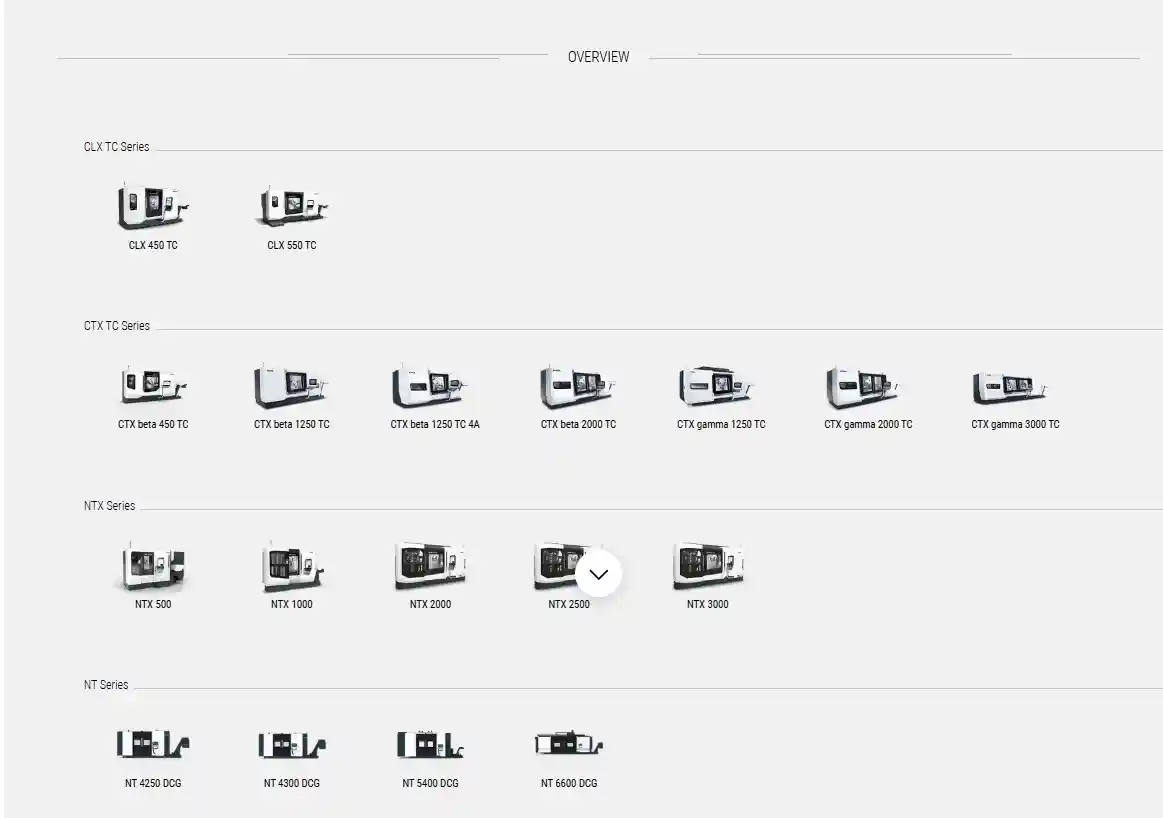

DMG Mori offers a wide range of turning-milling center products, from entry-level to high-end precision machining options.

CLX TC Series: Compact design with a compactMASTER turning-milling spindle and B-axis, replacing the turret to achieve 6-sided complete machining, ideal for small workpieces.

CTX TC Series: With machining lengths of up to 3,000 mm, the compactMASTER turning-milling spindle supports modular configurations like sub-spindles and tailstocks, suitable for large diameter and long workpieces.

NTX Series: Compact design with roller guideways providing exceptional rigidity, ideal for high-precision machining in space-constrained areas, handling large drive shafts and precision components.

NT Series: Box-in-box structure with an octagonal frame design offering excellent thermal stability and precision, suitable for high-precision machining, capable of processing workpieces up to 6,000 mm in length.

2. Haas Automation – High-Performance Multi-functional Turning-Milling

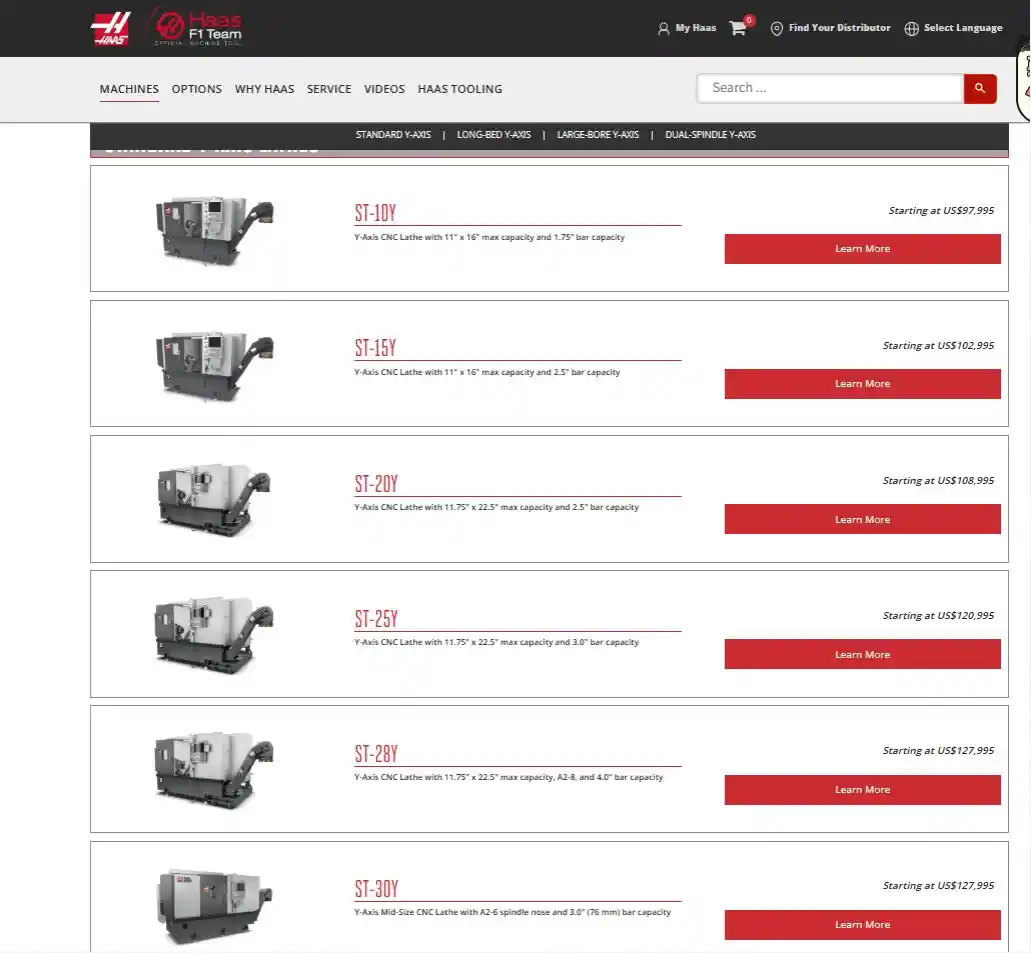

As the largest machine tool manufacturer in the United States and one of the biggest CNC machine tool manufacturers globally, Haas produces a full range of CNC products, including vertical machining centers, horizontal machining centers, turning centers, five-axis machining centers, rotary products, and comprehensive integrated automation solutions, such as automatic part loaders, pallet-changing systems, and six-axis robotic systems.

Haas turning-milling centers combine large stroke Y-axis, full C-axis motion, and high-performance power toolholders, providing workshops with multifunctional integrated machining solutions. They enable secondary milling operations (such as eccentric milling, drilling, and tapping) on the lathe, enhancing productivity and machining precision.

3. Mazak – Precision Machining and Efficient Production

When it comes to precision machining, Mazak is a brand that cannot be overlooked!

In September 1997, Mazak developed its first composite machining center with a Y-axis, the INTEGREX 200Y. In 2001, they developed the advanced INTEGREX e-series, further improving composite machining capabilities.

Mazak’s “INTEGREX” has become synonymous with composite machining and is a machine that integrates CNC turning and machining center functions into one, achieving both high-precision machining and high production efficiency.

4. Minnuo – Cost-effective CNC Solutions with Customization

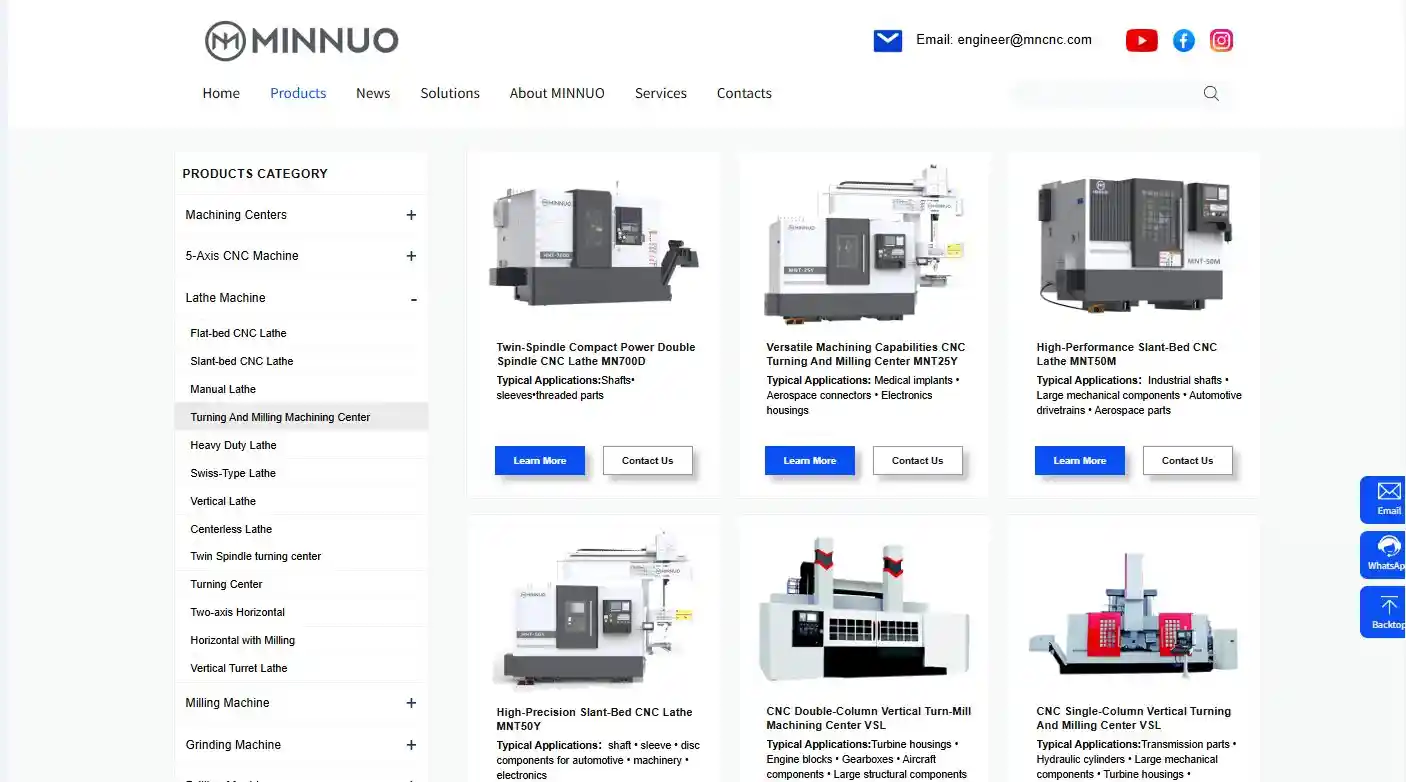

Minnuo, a company from Jiangsu, China, was founded in 1987 and is a leading provider of CNC machine tools and intelligent manufacturing solutions in China. They specialize in customizing equipment based on the actual needs of customers, ensuring that each turning-milling center achieves optimal machining results. Minnuo offers turning-milling solutions in the MNT and VSL series.

Minnuo places high importance on product quality, having received certifications such as ISO 9001 and ISO 14001. With the advantage of a well-established supply chain, abundant labor force, and convenient transportation in China, Minnuo provides a cost-effective option for many.

5. Tsugami – Precision, Speed, and Rigidity

Founded in 1937, Tsugami has always been dedicated to the development of precision technologies, providing high-precision, high-speed, and high-rigidity products according to customer requirements.

Tsugami’s turning-milling centers, such as the M06SY-Ⅱ/M08SY-Ⅱ and M06DY-Ⅱ/M08DY-Ⅱ, are equipped with 12-position turrets that can install milling tools, enabling process integration. Their abnormal load detection and anti-interference functions minimize mechanical damage and ensure safety, while the thermal displacement compensation technology ensures long-term stable production.

Conclusion

Whether you are looking for cost-effectiveness, intelligent solutions, or precise and efficient machining, each of these brands has its strengths. Based on your production needs and budget, choosing the right brand will significantly improve your production efficiency and product quality! If you have any questions about selecting a CNC turning-milling center, feel free to visit Minnuo, and let’s explore your needs together!

Email

Email sales1: +86 13295238763

sales1: +86 13295238763