A Comprehensive Comparison of Machine Tool Tool Holders and Rotary Tool Turrets: Structure, Efficiency, Precision, and Selection Guide

In the CNC lathe manufacturing industry, tool magazine systems and rotary tool turrets serve as core clamping mechanisms that directly determine production efficiency, machining accuracy, and corporate profitability. With the ongoing intelligent transformation of manufacturing, an increasing number of enterprises now consult keywords like "which is better between tool magazine and rotary turret", "differences between tool magazine and rotary turret", and "CNC lathe turret selection guide" when selecting CNC lathes. This article provides a comprehensive 4,000-word analysis covering structural principles, performance parameters, application scenarios, and cost considerations, helping manufacturers make precise equipment selections to enhance production competitiveness.

Ⅰ. Core Definitions of Tool Magazine and Rotating Tool Tower in Machine Tools: Understanding the Essential Differences in One Article

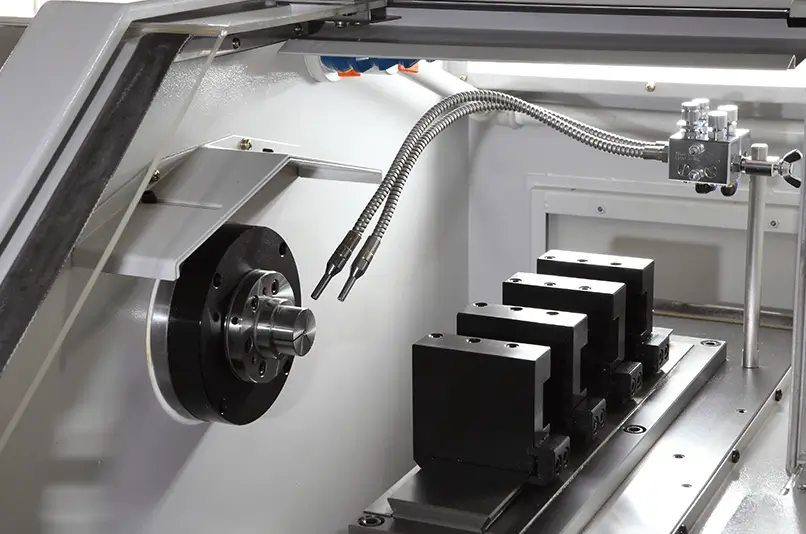

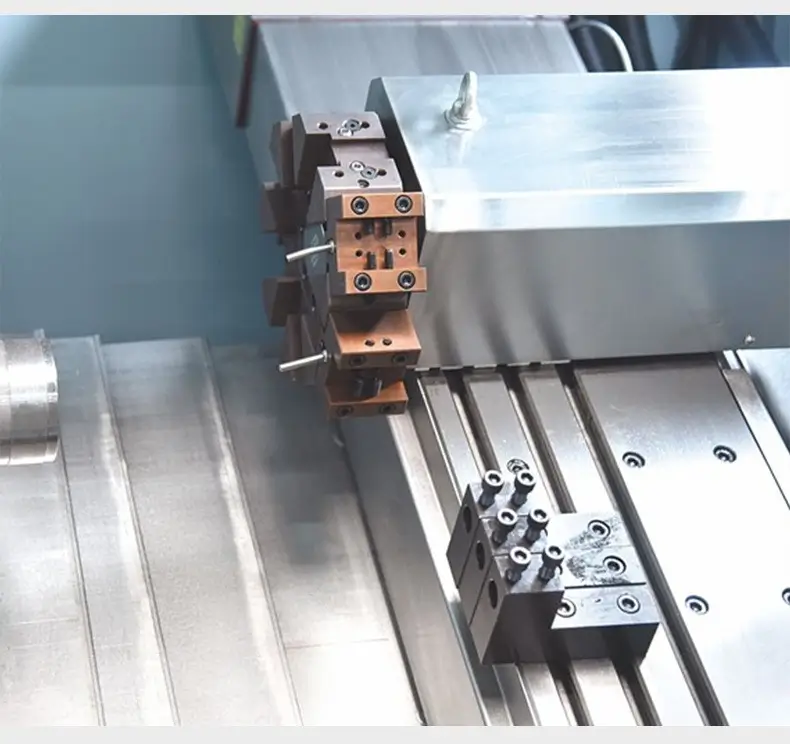

1. Tool magazine for machine tools: A simple yet efficient linear tool array

The tool post (also known as tool holder) is a fundamental tooling device commonly found in CNC lathes, widely used in small and medium-sized part machining. Its core structural feature is arranging multiple tools in a linear sequence along the machine's guide rails, enabling machining without rotation switching. The specific advantages and limitations are as follows:

- Structure: It is mainly composed of a knife holder, a guide rail slider, and a fixed bracket. It has no complex driving parts, simple installation and maintenance, and a low failure rate. This is also the key reason why "low maintenance cost of machine tool tool changer" has become an industry consensus.

- Working logic: During machining, the tool is precisely aligned with the machining area by translating the spindle or tool holder of the machine tool, without rotating action. Therefore, "the machine tool tool change speed is fast" is outstanding in single process machining.

- Tool compatibility: Conventional tool holders can accommodate 4-8 tools, mostly straight shank lathes, but cannot support power tools like milling cutters or drills. Their limited functionality explains why the "tooling scenarios" for machine tools are primarily focused on basic machining tasks.

- Industrial applications: In the mass production of electronic components, small hardware parts and standard parts, tool changer machine tools have become the first choice due to their "low cost and high stability". For example, mobile phone screws and micro shaft parts are mainly processed by tool changer machine tools.

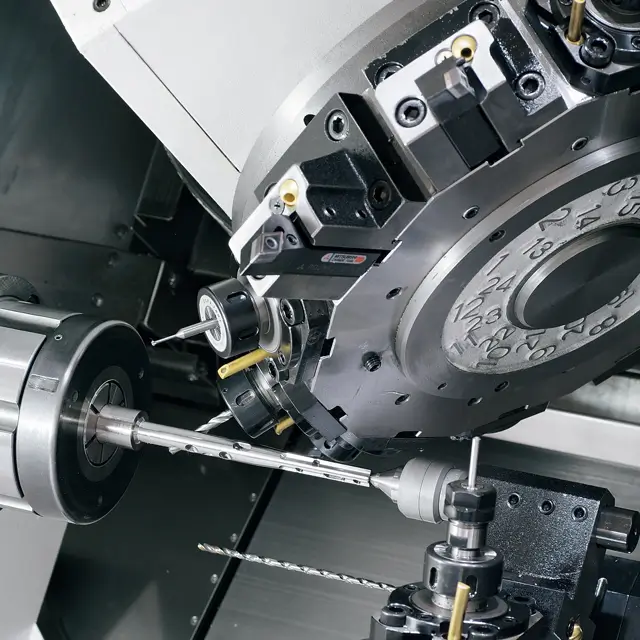

2. Rotating Blade Tower: A versatile "rotating blade library"

The rotary cutting turret (or simply 'cutting turret') is a core component in mid-to-high-end CNC lathes. It enables tool switching through motor-driven turret rotation, supporting multi-process compound machining. Its structural and performance features are as follows:

- The structure consists of a drive motor, indexing mechanism, locking device, and tool holder. Some high-end tool turrets are equipped with a power tool holder, enabling combined turning and milling operations. This is the core advantage of the "fully rotating tool turret function".

- Working logic: The tool is distributed in a circle on the turntable. During machining, the turntable rotates rapidly (the switching time is only 0.5-2 seconds). The tool is accurately positioned by the indexing mechanism, and then fixed by the locking device before machining is started. "The rotating tool tower has high efficiency in tool changing" has significant advantages in multi-process production.

- Tool compatibility: Standard tool turrets can accommodate 8-12 tools, while larger models support up to 16-24. They handle various tools including lathes, milling machines, drills, and taps, meeting complex machining needs. This makes 'rotary tool turrets for complex parts' a standard industry practice.

- Industry applications: In the machining of automotive parts, hydraulic parts and aerospace precision parts, the rotating tool tower has become the core machining equipment for engine shaft, hydraulic joint, aircraft landing gear parts and other products due to its ability of "continuous machining of multiple processes".

II. Comparison of key performance of tool changer and rotating tool turret: Data analysis of advantages and disadvantages

When enterprises search for "machine tool tool changer vs. rotary tool turret", they prioritize core metrics like efficiency, precision, and cost. Below, we present a data-driven comparison using 2025 industry benchmarks to thoroughly analyze their differences.

Dimensional comparison | Machine tool tool changer (2025 latest parameters) | Blade Tower (2025 Latest Parameters) |

working efficiency | Single-process tool change time: 0.2-0.5 seconds (no rotation, direct transfer to position); multi-process processing efficiency: 30%-50% lower than rotating tool turret (requiring frequent spindle movement) | Single-process tool change time: 0.5-2 seconds (rotation + locking); multi-process processing efficiency: 30%-50% higher than tool removal (continuous switching without spindle movement) |

working accuracy | Static accuracy: Tolerance ≤0.003mm (no rotational clearance, suitable for precision small parts); cumulative error across multiple processes: 0.005-0.01mm (caused by spindle movement) | Static accuracy: tolerance ≤0.005mm (with slight clearance in the rotating mechanism); cumulative error across multiple processes: 0.001-0.003mm (high precision of the indexing mechanism) |

Tool Compatibility | Supported tool types: only shaper tools; maximum tool quantity: 4-8; support for power tools: no | Supported tool types: turning tools, milling tools, drilling tools, taps, etc.; Maximum tool quantity: 8-24; Does it support power tools? Yes (high-end models) |

Cost input | Purchase cost: 150,000-250,000 yuan per unit (30%-50% lower than rotating blade towers of the same specification); annual maintenance cost: 5,000-10,000 yuan (no complex components) | Purchase cost: 250,000-800,000 yuan per unit (including higher-priced power knife holder models); annual maintenance cost: 10,000-30,000 yuan (requires bearing and locking parts replacement) |

Energy consumption level | Power: 3-5kW (simple structure, low energy consumption); annual power consumption: about 25,000 KWH (based on 8-hour shift) | Power: 5-15kW (with multiple drive mechanisms and high energy consumption); Annual electricity consumption: approximately 40,000-80,000 kWh (based on an 8-hour shift) |

floor space | Body size: 1.5m×0.8m×1.2m (compact design for space-saving); Suitable workshop area: 5-10㎡/ unit | Body size: 2.5m×1.2m×1.5m (complex structure, large size); suitable workshop area: 10-20㎡/ unit |

Supplementary Analysis: How Industry Trends Will Impact Performance in 2025

- Tool changer machine tools: With the growing demand for "lightweight machining", new tool changer machine tools will adopt high-precision guides (such as ball guides) in 2025 to improve static accuracy to 0.002mm, while optimizing the tool holder design to support some non-standard cutting tools, expanding the application range.

- Rotary Blade Tower: Driven by 'intelligent manufacturing', the high-end Blade Tower will be equipped with an AI fault warning system in 2025, which can predict maintenance needs 30 days in advance. Meanwhile, servo motor drive is adopted, and the blade change time is shortened to 0.3 seconds, further improving efficiency.

Ⅲ. Machine Tool Tooling and Rotary Tool Tower Selection Guide: Precise Matching by Scenario

Equipment selection is a critical concern for enterprises, as poor choices may result in idle machinery or underutilized capacity. Below, we provide scenario-based recommendations aligned with 2025 market demands, helping businesses avoid common pitfalls like improper tool magazine selection and flawed rotary turret configurations.

1. Three priority scenarios for machine tool tool positioning

- Scenario 1: Simple small batch production

For enterprises primarily manufacturing shaft components and sleeve parts (e.g., electronic connector pins, small bearing sleeves) with diameters ≤50mm, where machining processes only involve external cylindrical turning and end face turning, tool changer lathes are the optimal choice. A case study from an electronics factory demonstrates that using tool changer lathes to process φ8mm copper shafts achieves a single-shift output of 2,000 units, saving 30% on electricity costs compared to rotary turret lathes.

- Scenario 2: High-precision static processing requirements

When component tolerance requirements are ≤0.005mm (e.g., precision instrument shafts, micro motor rotors), the gapless tool magazine structure of machine tools ensures machining accuracy. Comparative tests by an instrument manufacturer revealed that φ10mm steel shafts machined by tool magazine machines showed 0.002-0.003mm accuracy variation, while those processed by rotary turret machines exhibited 0.003-0.005mm variation.

- Scenario 3: Small and medium-sized enterprises with limited budgets

For startups or small manufacturers with a budget of ≤250,000 yuan per machine tool and aiming to reduce maintenance costs, tool changer systems are more suitable. Take a hardware factory as an example: purchasing two tool changer systems (200,000 yuan per unit) results in annual maintenance costs of just 15,000 yuan, while a rotary turret system (350,000 yuan per unit) with equivalent capacity incurs 30,000 yuan in annual maintenance expenses.

2. Prioritize 3 types of scenarios for rotating blade towers

- Scenario 1: Complex composite parts processing

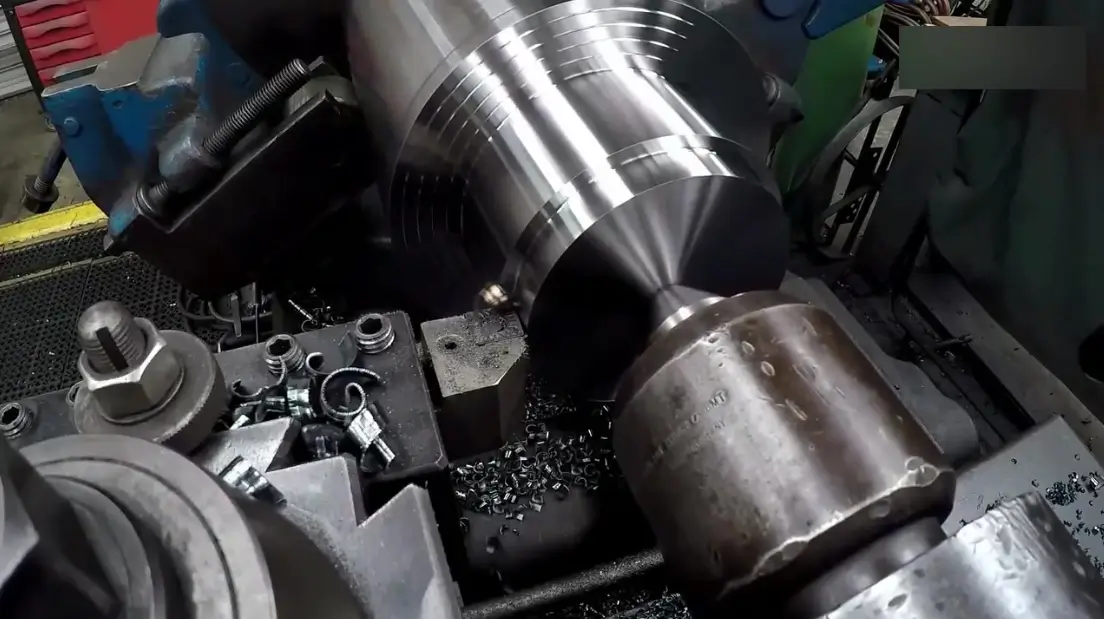

For multi-step machining processes (e.g., turning + groove milling + drilling + tapping, as seen in motor shafts and hydraulic connectors), the multi-tool adaptability of rotary tool turrets becomes essential. A automotive component manufacturer utilizes a rotary turret machine with power tool holders to process engine camshafts, enabling single-pass operations for external cylindrical turning, keyway milling, and oil hole drilling. This setup achieves a daily output of 800 units per shift, representing a 60% efficiency improvement compared to conventional tool-change machines that require multiple equipment setups.

- Scenario 2: High productivity and efficiency requirements

When handling high-volume orders (≥500 units per shift) with tight deadlines (e.g., 2,000 units daily during peak seasons), the rapid tool change capability of rotary turret machines significantly boosts production efficiency. For example, a hydraulic component manufacturer achieved 1,200 units per shift using rotary turret machines for valve core machining during peak seasons, while conventional tool-change machines could only process 700 units, effectively meeting urgent customer demands.

- Scenario 3: CNC machining requirements

When machining components requiring simultaneous turning and milling operations (such as shafts with flat milling grooves or sleeves with radial holes), the rotating tool turret's power tool holder proves to be the optimal solution. A leading aerospace component manufacturer utilizes high-end rotating tool turret machines to process aircraft landing gear connectors. Through single-chamber clamping, the system achieves precision machining including external cylindrical turning, flange milling, and threaded hole drilling, delivering a machining accuracy of 0.002mm that fully complies with aviation industry standards.

IV. Clarification of Common Misconceptions on Tool Magazine and Rotating Tool Tower in Machine Tools: Latest Industry Insights for 2025

In the process of "tool changer and rotating tool turret selection", enterprises are often misled by traditional cognition. The following 5 common misunderstandings are clarified based on the development of the industry in 2025:

Myth 1: "The precision of rotating blade tower must be higher than that of machine tool blade arrangement"

The latest understanding for 2025: Accuracy depends on the processing scenario, not the type of equipment.

- Static single-process machining (e.g., precision small part turning): the tool changer has no rotating clearance, resulting in superior precision (e.g., φ5mm shaft machining with a tool changer accuracy of 0.002mm and a rotating tool turret of 0.003mm);

- Multi-process machining (e.g., turning + milling + drilling): The rotary turret indexing mechanism ensures precision with minimal cumulative errors (for multi-process parts, tool setting error 0.008mm vs. turret indexing error 0.003mm).

Test data from a precision machining laboratory in 2025 showed that in φ10mm precision shaft machining, the tool rejection rate was 98% for conventional lathes and 95% for rotary turret lathes. For multi-step part machining, the rates were 99% for rotary turret lathes and 92% for conventional lathes.

Myth 2: "Machine tool tooling can only process small parts, can not process large parts"

The latest understanding in 2025: Large cutting tools have achieved large piece processing, breaking the size limit.

In 2025, the industry will introduce large-format tool changer machines with processing diameters of ≥300mm, featuring heavy-duty guides and reinforced tool holders. These machines can handle large flanges and shaft components (such as φ500mm bearing sleeves). A heavy machinery manufacturer has adopted such equipment to process large flange end faces, achieving a single-shift output of 50 units with 0.005mm machining accuracy. The maintenance costs are 40% lower compared to traditional large rotating turret lathes.

Myth 3: "Rotating Blade Tower is expensive and small and medium-sized enterprises can not afford it"

The latest 2025 insight: The cost of mid-to-low-end rotary turret machine tools has dropped, making them affordable for small and medium-sized enterprises.

By 2025, entry-level rotary turret lathes (8-spindle, non-powered) will drop to 250,000-300,000 yuan, narrowing the price gap with high-end tool changer lathes (200,000-250,000 yuan). A small component manufacturer procured two entry-level rotary turret lathes in 2025 to process multi-step parts. This upgrade boosted single-shift output from 300 to 500 pieces, recouping the additional investment within six months.

Myth 4: "Machine tool tool changer does not need maintenance, rotating tool turret maintenance is complex"

The latest 2025 understanding: Both require regular maintenance, and blade maintenance is simpler but should not be ignored.

- Tool maintenance: clean guide rails and check the fastening of tool seat every month, and replace guide rails lubricating oil every quarter. The annual maintenance cost is 5000-10000 yuan.

- Tower of Hana maintenance: Clean the turntable every month, check the locking device, replace the bearing grease every quarter, and replace the indexing mechanism parts every year. The annual maintenance cost is 10,000-30,000 yuan.

A processing plant neglected the cleaning of the guide rail of the cutting machine, resulting in the wear of the guide rail. The maintenance cost reached 20,000 yuan, which was higher than the routine maintenance cost of the rotating knife tower.

Myth 5: "Intelligent upgrading is only possible with rotating tool turrets, not machine tool tool arrangement"

The latest cognition in 2025: The tool changer of machine tool has achieved basic intelligence to meet the needs of small and medium-sized factories.

By 2025, the new generation of tool changer machine tools will be equipped with PLC control systems, enabling automatic feeding and processing parameter storage (supporting over 100 part parameters). Some models will also feature remote fault diagnosis. An electronics manufacturer has adopted intelligent tool changer machine tools, achieving 24/7 unmanned processing through remote monitoring. This has boosted production capacity by 25%, with the system's intelligence level approaching that of entry-level rotary turret machine tools.

Ⅴ. Practical Suggestions for Machine Tool Tooling and Rotary Tool Turret Selection in 2025: A Pitfall Avoidance Guide

1. Identify your core needs: 3 key questions

Before purchasing, enterprises need to answer the following 3 questions to avoid blind selection:

- Question 1: "What are the main machined parts? How many processes are there?" (e.g., simple small parts with single-process tool selection, complex parts with multi-process tool turret selection);

- Question 2: "What's the production capacity requirement? Is the delivery schedule tight?" (For example, choose a turret for orders ≥500 units per shift, or a linear cutter for ≤300 units).

- Question 3: "What's the budget range? Does it include procurement and maintenance costs?" (If the total budget is ≤300,000 yuan, choose the blade; if ≥300,000 yuan, consider the Blade Tower).

2. Field investigation and trial processing: indispensable steps

- Check the manufacturer's strength: choose a manufacturer with more than 5 years of establishment and patented technology (such as the top 10 CNC lathe brands in the industry in 2025), and avoid purchasing inferior equipment from small factories;

- Trial machining test: Take your own parts to the manufacturer's workshop for trial machining, and compare the machining accuracy and efficiency of the tool holder and the tool turret machine tool (for example, try to machine 100 parts, and calculate the qualified rate and time);

- Ask about after-sales service: Check if the manufacturer offers on-site installation, hands-on training (at least 3 days), a warranty of over 1 year, and local repair outlets (respond within 24 hours).

3. Combine with future development plan: reserve space for upgrade

- If the enterprise plans to expand the processing of complex parts within 3 years, it can choose the rotating tool tower machine tool which supports the installation of power tool seat in the later stage;

- If the workshop may expand the production capacity in the future, the equipment with modular design can be selected to facilitate the addition of spindle or tool position in the later stage;

- Keep an eye on industry technology trends and prioritize equipment compatible with the Industrial Internet (such as MES system integration) to lay the foundation for smart factory construction.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763