How Chinese Machine Tools Support Automated Manufacturing in Brazil

In Brazil, the manufacturing industry is facing unprecedented pressure: how can it improve production efficiency while reducing pollutant emissions in the face of the global green transformation? The electrification of heavy machinery and the application of alternative fuels have become key to enhancing competitiveness. However, can Brazilian enterprises achieve this goal through automation and sustainable technology amidst intense market competition?

Chinese machine tool technology, with its leading automation, intelligence, and energy-saving capabilities, can help Brazilian manufacturers overcome bottlenecks, enhance production efficiency, reduce energy consumption, and meet strict environmental requirements, thus providing strong support for their green transformation.

Next, we will delve into how technological solutions can address the three major challenges facing Brazil’s manufacturing industry.

1. Overcoming Efficiency Challenges

Problem 1: How to reduce dependence on labor and achieve continuous automated production?

Brazilian manufacturing faces a high dependence on labor, leading to low and unstable production efficiency. Automation technology becomes the key to solving this problem.

Technical Solution:

Modular Automation Units

With standardized robotic integration units (e.g., ISO 9409 interface), Chinese machine tools provide modular automation upgrade solutions that allow traditional machines to be easily transformed into automated devices. This avoids the high cost of complete line retrofits and saves up to 60% of investment.

Chinese Machine Tool Assistance:

Equipment Upgrades and Efficient Integration: Manufacturers like Huazhong CNC and Shenyang Machine Tool offer high rigidity, precision automation systems that seamlessly integrate with existing machines to automate production processes.

Intelligent Control and Self-Diagnostics: Intelligent control systems automatically adjust process parameters and feature self-diagnosis functions, reducing manual intervention and improving production stability.

Flexible Scalability: Modular designs support gradual expansion of automation units, providing flexibility to respond to changing production needs and ensuring continuous production.

Through these technologies, dependence on labor is effectively reduced, and continuous, stable production is achieved.

Problem 2: How to reduce unplanned downtime?

Machine downtime not only results in production losses but also increases maintenance costs and affects production stability. Reducing unplanned downtime has become an important issue for Brazilian manufacturers.

Technical Solution:

Intelligent Monitoring Systems

Equipped with industrial-grade intelligent monitoring modules, these systems offer real-time insights into machine operation status, supporting remote data viewing and analysis.

Fault Prediction and Warning

By utilizing big data and algorithm models, the system can predict the wear trend of critical components, preventing sudden failures.

Pre-emptive Maintenance and Spare Parts

The system can automatically issue maintenance reminders and spare part alerts, allowing for pre-dispatched spare parts and zero-delay repairs.

These solutions integrate technologies accumulated by machine tool companies like Minnuo in the fields of intelligent monitoring and predictive maintenance.

2. Core of Green Transformation: Energy-Saving and Carbon Reduction Technology Selection Guide

Problem 3: How to cope with Brazil’s high electricity prices? (Industrial electricity price: $0.18/kWh)

Brazil’s high electricity prices bring significant cost pressures to manufacturers, especially for production equipment that operates for long hours, where electricity costs are a major expense.

Technical Decision Tree:

Energy Recovery System and IE4 Motors: For machine tools with high annual cutting hours (over 4000 hours), using an energy recovery system and IE4 motors can save over 35%. For short-running equipment, using IE4 motors can save 20%-25%.

Brands like Shenyang Machine Tool and Dalian Machine Tool have widely applied these technologies and provide solutions in the Brazilian market, helping local customers reduce energy costs effectively.

Problem 4: How to meet stringent emission standards?

Brazil’s environmental regulations require manufacturers to reduce emissions of waste gases and wastewater, particularly controlling VOCs and PM2.5, which impose higher requirements on production processes and equipment.

Technical Combination:

Pollution Type | Solution | Implementation Effect | Cost Recovery Period |

Cutting Fluid | Micro-lubrication (MQL) + Vacuum Chip Removal | 90% reduction in VOCs, 95% reduction in waste fluid | <14 months |

Oil Mist | Electrostatic Filtering + Activated Carbon Adsorption | 99.9% PM2.5 filtration efficiency | <18 months |

Practical Recommendation: Brazilian manufacturers can prioritize the retrofitting of precision machining processes (which account for 80% of total pollution load), using Huazhong CNC’s micro-lubrication system and vacuum chip removal devices to reduce pollutant emissions and lower waste fluid treatment costs.

3. Breaking through the Green Power Equipment Manufacturing Barrier

Problem 5: How to process special parts for electric machinery?

The special parts for electric vehicles and hydrogen equipment require high precision and performance in machining, especially for corrosion-resistant alloys and composite materials, placing high demands on machine tools.

Material-Process Matching Table:

Part Type | Material | Recommended Machining Solution | Precision Assurance Measures |

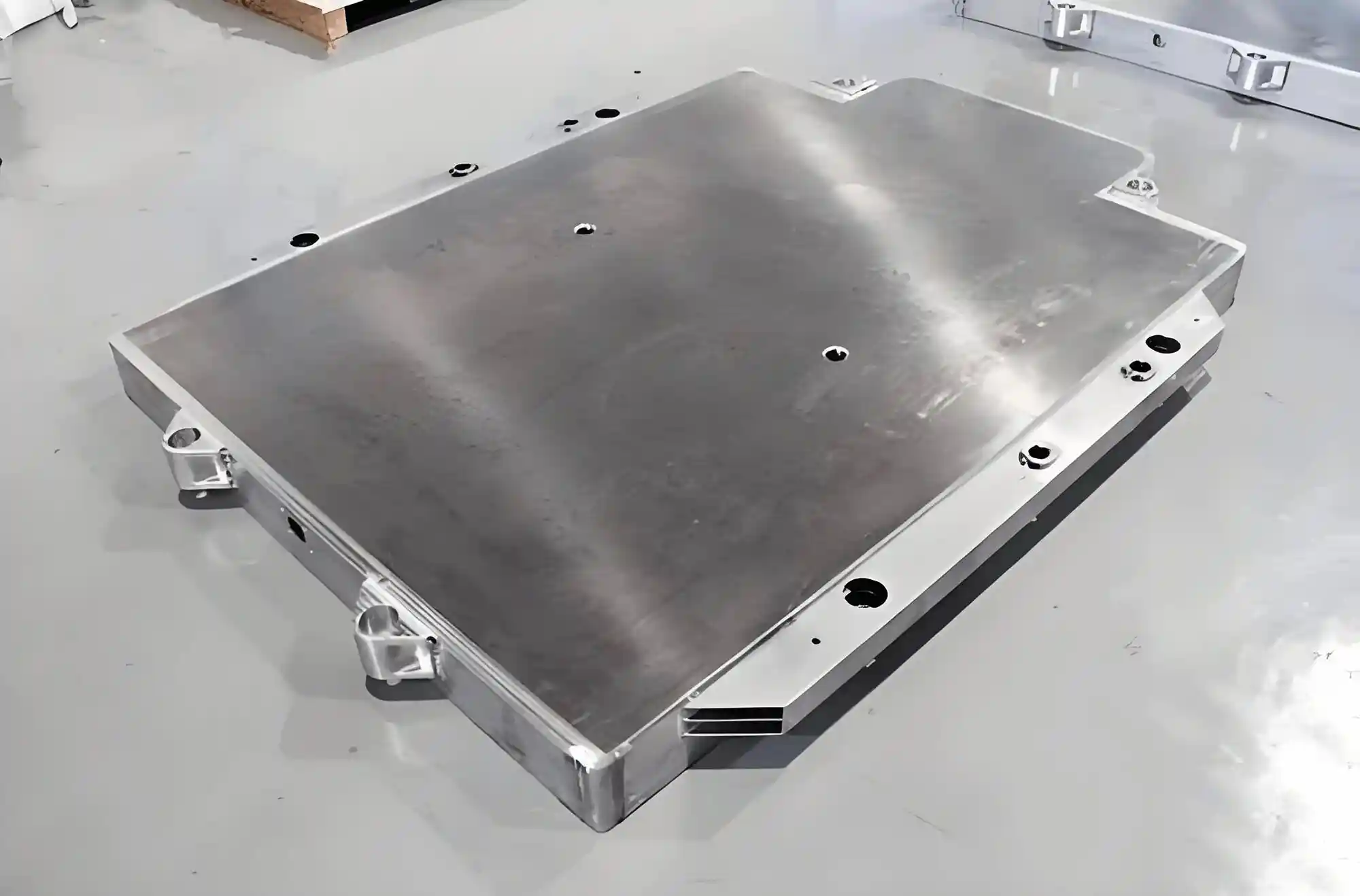

Battery Tray | Carbon Fiber Composite | 5-axis machine + diamond-coated tools | Constant temperature workshop (23±1°C) to prevent delamination |

Biofuel Nozzle | Hastelloy C276 | High-pressure cooling (10 MPa) + ceramic blades | Online surface roughness detection |

Shenyang Machine Tool and Dalian Machine Tool’s 5-axis machine systems, combined with high-precision diamond-coated tools, can efficiently process carbon fiber composites and corrosion-resistant alloys, meeting the machining needs for battery trays, hydrogen storage tanks, and other high-precision components.

Problem 6: How to deal with machining deformation in a tropical climate?

Brazil’s hot climate presents challenges to machine tool stability and machining accuracy, especially during large-scale production.

Thermal Compensation Technology Key Elements:

Machine Base Material: Mineral casting (thermal expansion coefficient < 0.02μm/m·℃)

Spindle Thermal Expansion Real-Time Compensation: Laser calibration accuracy of 0.5μm

Cutting Fluid Temperature Control System: ±0.5°C

Hexagon’s high-precision thermal compensation technology, combined with temperature control systems, effectively addresses errors caused by thermal expansion, ensuring that machines maintain high-precision machining in Brazil’s tropical climate.

Conclusion

When selecting machine tools, Brazilian manufacturers should focus on the total lifecycle cost (LCC) of equipment rather than just the initial investment. Chinese machine tool companies like Huazhong CNC, Dalian Machine Tool, and Shenyang Machine Tool, with their efficient, green, and intelligent technical solutions, can provide comprehensive technical support to help Brazilian manufacturers achieve a successful green transformation.

We believe that through cooperation, Brazilian manufacturing will take solid steps on the path of green manufacturing, jointly promoting sustainable development. If you are looking for innovative machine tool solutions, Minnuo is ready to be your reliable partner, supporting Brazil's green manufacturing future.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763