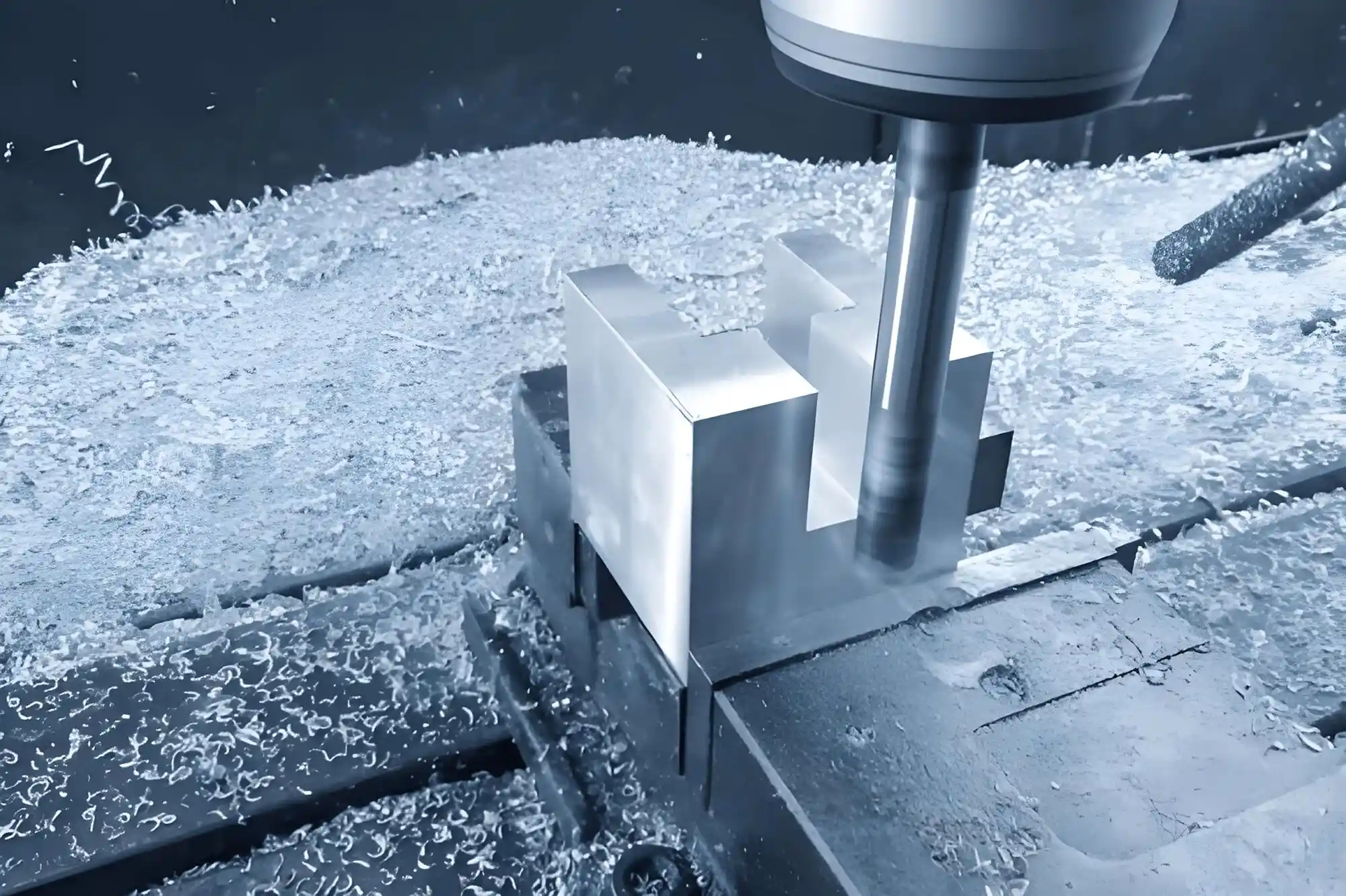

How to Adjust Feed Rate to Improve Surface Quality in Vertical CNC Milling Machines?

Although the CNC milling machine's control system can precisely manage the machining process, improving surface quality is not a one-step task. Feed rate adjustment, as an important factor affecting surface precision, is often overlooked or underutilized.

Adjusting the feed rate can be achieved through closed-loop control systems, which monitor cutting forces and vibrations in real-time, automatically optimizing the feed rate to ensure surface quality. Additionally, smart sensors and CNC programming optimization can dynamically adjust the feed rate based on the cutting state, adapting to the needs of different machining stages.

This article will explore the impact of feed rate on surface quality in vertical CNC milling machines and analyze how to scientifically adjust the feed rate to optimize surface finish.

I、What is Feed Rate?

Feed rate refers to the distance the tool moves along the surface or axial direction of the workpiece per minute during the machining process.

Why is Feed Rate Important?

The adjustment of feed rate not only affects machining efficiency but directly impacts surface quality. Properly set feed rates ensure a smooth, efficient cutting process, avoiding excessive vibration, heat accumulation, and tool wear.II、Relationship Between Feed Rate and Surface Quality

Feed rate is one of the key factors influencing surface quality, directly affecting surface roughness, smoothness, and cutting marks.

Effects of Low Feed Rate

Low feed rates usually result in smoother and finer cutting, leading to a smoother surface. However, excessively low feed rates can cause some issues:Longer Machining Time: The cutting time increases, potentially reducing machining efficiency.

Increased Tool Wear: Low feed rates can lead toheat accumulation, increasing the risk of tool wear.

Effects of High Feed Rate

Conversely, higher feed rates typically improve machining efficiency but may have adverse effects:Increased Surface Roughness: Excessive cutting forces can cause surface scratches, burrs, and irregular cutting marks.

Heat Accumulation and Shortened Tool Life: High-speed cutting generates excessive heat, affecting surface quality and accelerating tool wear.

III、Technical Methods for Adjusting Feed Rate

Modern vertical CNC milling machines utilize advanced technologies to help operators precisely adjust feed rates and dynamically modify them based on feedback during the machining process:

Closed-Loop Control Systems: These systems monitor feed rate, cutting forces, and vibrations in real-time, automatically adjusting the feed rate to ensure surface quality.

Smart Sensor Technology: Sensors monitoring cutting forces, temperature, and vibrations adjust the feed rate in real-time to avoid surface defects.

CNC Programming Optimization: Properly programming CNC routines to set dynamic feed rate adjustment rules helps adapt to different machining stages.

IV、What Are the Effects of Improper Feed Rate on Other Aspects?

Improper feed rate settings can affect more than just surface quality. Here are several common negative impacts:

Increased Tool Wear: High feed rates increase tool load, causing excessive wear and even tool breakage.

Vibration and Resonance: Incorrect feed rates can cause machine vibrations or resonance, increasing surface roughness and machining errors.

Reduced Machining Accuracy: Excessively fast feed rates may result in insufficient contact between the tool and workpiece, affecting machining accuracy, leading to dimensional errors or surface defects.

Waste of Machining Time: Low feed rates may lead to prolonged machining times, reducing production efficiency and increasing costs.

How to Choose the Correct Feed Rate for Different Materials?

Each material has different cutting characteristics, so the choice of feed rate must be tailored to each material. Selecting the correct feed rate not only enhances machining efficiency but also avoids surface damage.

V、Common Materials and Feed Rate Recommendations

Material | Recommended Feed Rate | Influencing Factors |

Aluminum Alloys | High Feed Rate | Aluminum alloys are soft, suitable for higher feed rates to improve machining efficiency. |

Steel | Medium Feed Rate | Steel is hard, and a moderate feed rate helps balance cutting forces and tool life. |

Low to Medium Feed Rate | Titanium alloys are hard and brittle, requiring lower feed rates to reduce cutting heat and tool wear. | |

Composite Materials | Low to Medium Feed Rate | Composite materials are complex, requiring lower feed rates to minimize surface damage. |

Key Selection Factors

Hardness: Harder materials typically require lower feed rates to reduce cutting forces.

Toughness: Tougher materials can tolerate higher feed rates to improve machining efficiency.

Thermal Conductivity: Materials with low thermal conductivity (such as titanium alloys) need controlled feed rates to avoid excessive heat accumulation.

VI、How to Choose the Correct Feed Rate for Different Tools?

The type and geometry of the tool directly influence the feed rate during cutting. Incorrect tool selection and mismatched feed rates can lead to tool wear, workpiece damage, and surface defects.

Tool Type and Feed Rate Matching

Carbide Tools: Suitable for high-hardness materials, carbide tools can withstand higher feed rates and provide a longer tool life.

High-Speed Steel Tools: Suitable for medium to low hardness materials, requiring moderate feed rates to balance surface quality and tool life.

Coated Tools: Coated tools have excellent wear resistance and can handle higher feed rates, but should be adjusted based on specific machining tasks.

Tool Geometry Impact on Feed Rate

Rake Angle: Larger rake angles help reduce cutting forces and can support higher feed rates.

Relief Angle: Larger relief angles reduce friction between the tool and workpiece, suitable for high feed rate operations.

Cutting Edge Shape: Round cutting edges are suitable for stable feed rates, while sharp cutting edges are ideal for fine machining.

VII、Other Cutting Parameters to Consider Besides Feed Rate

When optimizing surface quality in vertical CNC milling machines, other cutting parameters must also be considered in a coordinated optimization process:

Spindle Speed: Spindle speed, along with feed rate, determines cutting speed. Low spindle speed with low feed rate can yield smoother surfaces, but too low may lead to heat buildup.

Cutting Depth: A larger cutting depth increases cutting forces, affecting surface quality. Typically, shallow cuts improve surface finish.

Cutting Force and Vibration: Excessive cutting forces cause vibrations that affect machining accuracy. Using appropriate cooling fluids and reducing cutting forces improves surface quality.

VIII、Difference Between Cutting Speed and Feed Rate

Cutting speed refers to the relative speed at the contact point between the tool and workpiece, usually measured in meters per minute (m/min) or feet per minute (ft/min).

Cutting speed is closely related to tool diameter, spindle speed, and other parameters, with the formula:

Vc==π×D×n

Where:

Vc is the cutting speed (m/min),

D is the tool diameter (m),

n is the spindle speed (rpm).

Summary of Differences

Parameter | Cutting Speed (Vc) | Feed Rate (F) |

Definition | Relative speed at the tool-workpiece contact point | Speed at which the tool moves along the workpiece |

Units | m/min or ft/min | mm/min |

Influencing Factors | Tool speed, tool diameter, material type | Cutting depth, tool geometry, material properties |

Effect | Primarily affects tool wear, cutting heat, and material removal | Directly influences cutting load, machining accuracy, and surface quality |

IX、Conclusion

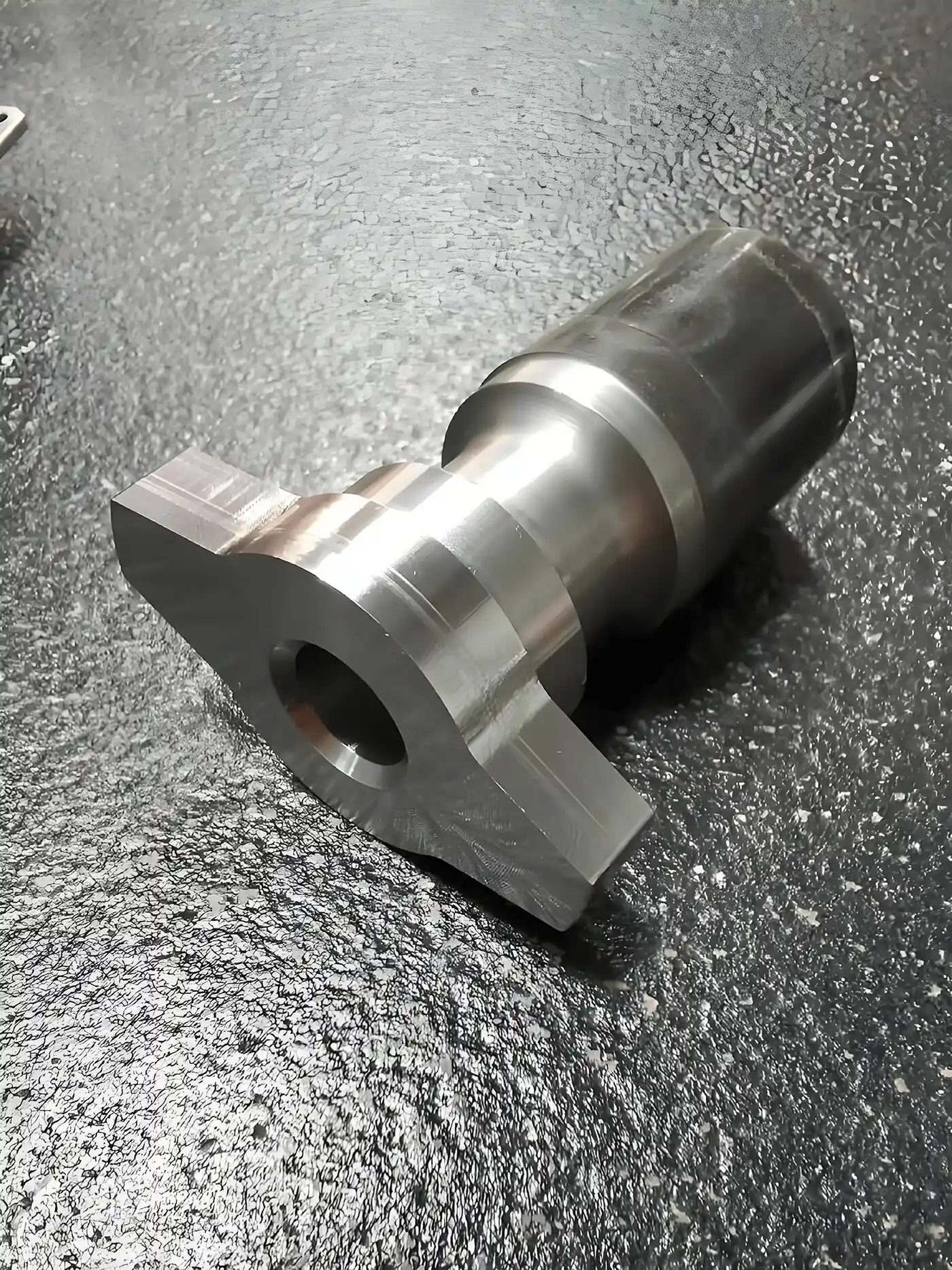

In vertical CNC milling machine operations, adjusting feed rate is crucial for surface quality. By properly selecting and precisely controlling the feed rate, surface finish can be significantly improved, tool wear minimized, and production efficiency increased. However, feed rate is not the only influencing factor. Material type, tool selection, cutting depth, and other parameters must be considered in coordination.

If you encounter any issues or have questions about adjusting feed rates in your machining process, feel free to contact us at Minnuo. As a solution-oriented machine tool manufacturer with years of experience, we offer professional technical support and solutions to help you improve machining quality and productivity.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763