How to Solve the Taper Problem in CNC Lathe Machining?

In CNC lathe machining, taper refers to the phenomenon where the diameter of a workpiece gradually changes along the axial direction. For those of us pursuing precision manufacturing, eliminating taper is crucial—it directly affects the assembly accuracy and performance of parts.

To solve taper problems in CNC lathes, you can start from multiple aspects such as machine calibration, tool adjustment, and workpiece clamping. By conducting precise inspections to find the root cause, targeted measures can then be taken.

Next, I will give you a detailed introduction to the concept of taper—from its causes to detection, and then to specific solutions and preventive measures—helping you fully master the techniques for dealing with taper issues.

1. What is Taper?

Taper is the condition where there is a diameter difference between the two ends of a workpiece, showing a regular change along the axial direction. In practice, you may find that the diameter near the spindle end and the diameter far from the spindle end of the same workpiece are not the same; this can be clearly detected when measuring with calipers.

2. Different Types of Taper

Type | Characteristics |

Intentional Taper | A taper deliberately machined according to design requirements, such as tapered shafts or tapered holes, with specific angle and dimension requirements. |

Unintentional Taper | A taper accidentally produced during machining due to various factors, which does not meet design standards and affects part quality. |

3. Impact of Taper on Part Function and Quality

Unintentional taper can cause parts to fail in proper assembly. For example, when fitting a bearing to a shaft, taper can result in uneven fit clearance, affecting transmission accuracy; for sealing parts, taper may cause poor sealing and leakage.

4. Common Causes of Taper in CNC Lathe Machining

Machine-related factors

Spindle axis misalignment: When the spindle rotation center is not parallel to the guideways, the workpiece will develop a taper during machining.

Guideway wear or damage: After long-term use, guideway precision decreases, causing tool movement trajectory deviation and thus taper

Tailstock alignment issues: If the tailstock center is not coaxial with the spindle center, the workpiece will be unevenly stressed during machining, forming taper.

Tool-related issues

Dull or improperly sharpened cutting tools: A blunt tool increases cutting force, causing slight tool deflection and taper.

Incorrect tool post alignment: If the tool post is not perpendicular to the spindle axis during installation, the workpiece will have a taper.

Tool deflection due to improper settings: Excessive tool overhang or insufficient clamping force can cause the tool to deflect under cutting force, producing taper.

Workpiece-related factors

Workpiece deflection under cutting force: Long, slender workpieces with poor rigidity can bend during cutting, leading to taper.

Insufficient clamping or improper fixturing: Loose clamping can cause workpiece movement during machining, producing taper.

Material inconsistency: Uneven material hardness can cause unstable cutting forces, resulting in taper.

Operating parameter issues

Incorrect feed rate and spindle speed: Excessively high feed rates or improper spindle speeds can cause large changes in cutting force, leading to tool or workpiece deflection.

Improper cutting depth: Excessive cutting depth increases cutting force, making deformation of the workpiece or tool more likely.

5. How to Detect Taper in CNC Lathe Workpieces

Measurement tools and techniques

How to accurately measure taper on a workpiece:

1.Place the finished workpiece on a horizontal support to ensure stability.

2.Use a micrometer to measure the diameter near the spindle end (D1) and record the value.

3.Measure the diameter at the far end (tailstock end) of the workpiece (D2) and record the value.

4.Measure the distance (L) between the two measuring points.

5.Calculate taper using the formula:

Taper = (D1 - D2) / L

Determining the severity of taper from measurements:

Generally, when the calculated taper value exceeds the design tolerance of the part, adjustments are necessary. If the taper is small, slight adjustments to machining parameters may suffice; if large, check machine alignment, tooling, and other factors.6. Steps to Solve Taper Problems in CNC Lathe Machining

Adjusting machine alignment

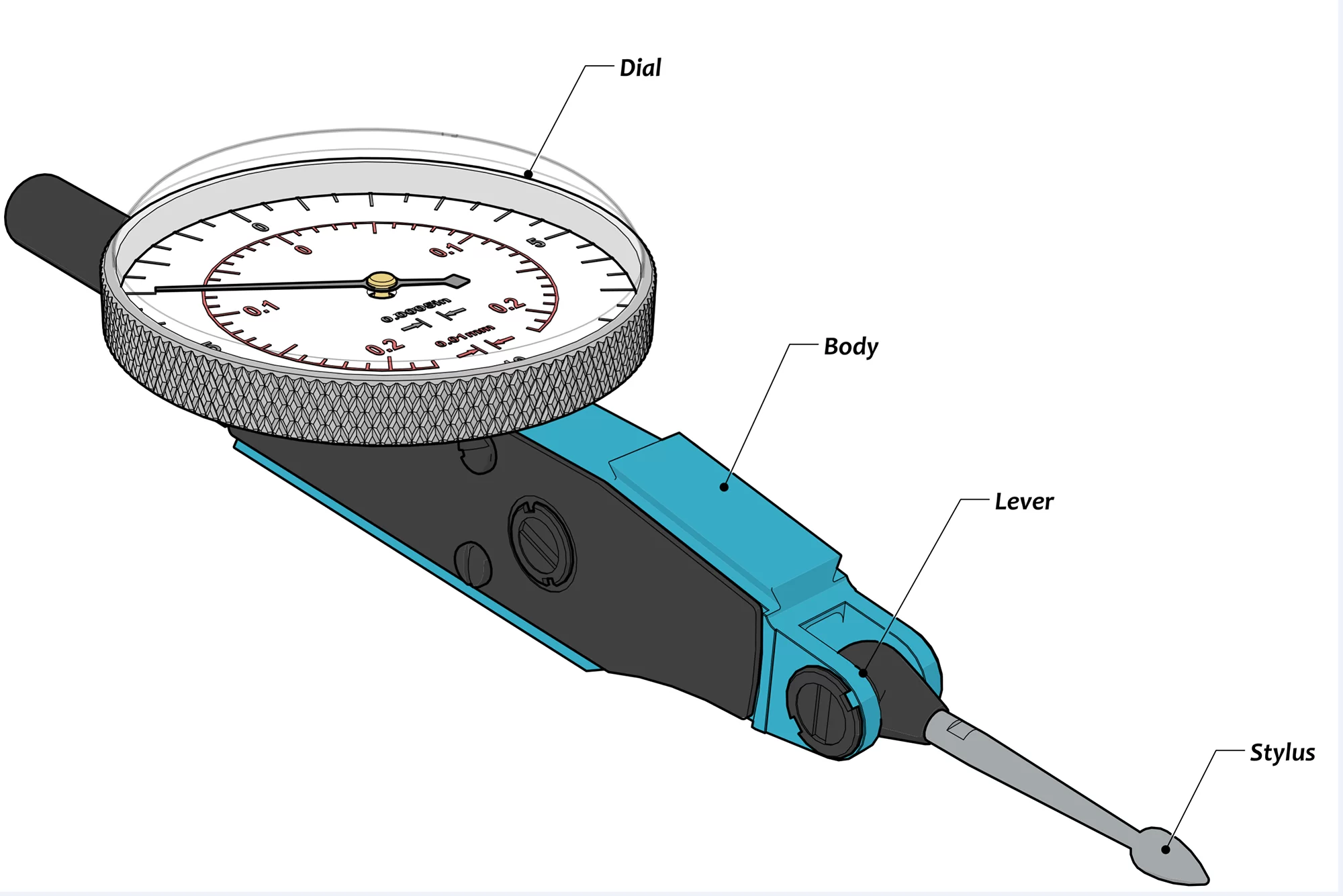

Align spindle axis with guideways: Loosen the spindle box fixing bolts, use a dial indicator to check spindle-to-guideway parallelism, adjust shims as needed, and retighten bolts.

Correct tailstock alignment: Fix a dial indicator on the tool post with the stylus touching the tailstock center. Move the tool post and observe reading changes. Adjust tailstock position until readings are within allowable limits.

Solving tool-related issues

Replace or repair cutting tools: Regularly inspect tools for wear, replace blunt or damaged tools, and sharpen resharpenable tools to the correct angles to ensure sharpness.

Adjust tool post alignment: Fix a dial indicator to the spindle with the stylus touching the tool post side. Rotate the spindle and adjust the tool post until it is perpendicular to the spindle axis.

Improving workpiece setup

Strengthen clamping: Select suitable fixtures according to workpiece shape, increase clamping points, and ensure firm clamping; use additional supports if necessary.

Reduce workpiece deflection: For slender workpieces, use a follow rest or steady rest to improve rigidity and reduce deformation during cutting.

Optimizing operating parameters

Adjust feed rate, spindle speed, and cutting depth: Select parameters based on material and tool performance to avoid excessive cutting force; use step cutting to reduce deformation.

7. Preventive Measures to Avoid Taper in CNC Lathe Machining

Regular machine maintenance and calibration: Lubricate, clean, and calibrate guideways, spindles, tailstocks, and other components according to the machine manual.

Proper tool selection, handling, and storage: Choose tools according to material and process requirements, clean after use, and store on dedicated racks.

Correct workpiece setup and clamping procedure: Clean positioning and clamping surfaces before fixturing, ensure accurate positioning, and apply appropriate clamping force.

Operator training and best practices: Provide regular training so operators understand machine performance, machining processes, and troubleshooting techniques.

8. Measurement Technologies that Help Reduce Taper Problems

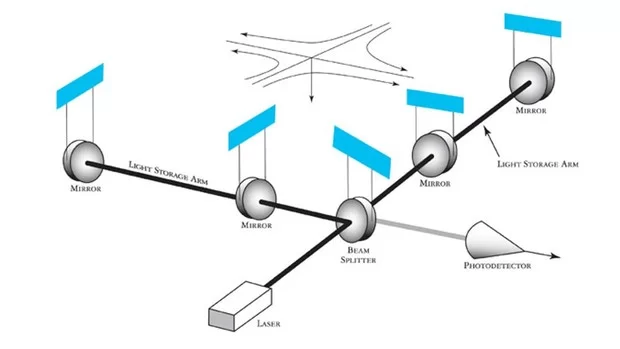

Laser interferometry:

Uses a laser interferometer to monitor axis movement accuracy in real time, capturing displacement errors and enabling precise machine adjustments to reduce taper caused by motion deviations.

Coordinate measuring machine (CMM):

Measures workpiece blanks before machining to detect initial deviations, and inspects semi-finished parts during processing to detect taper trends early.

In-process real-time measurement:

Integrates sensors into the CNC lathe to measure dimensions during cutting and feed back data to the control system for automatic tool path and parameter adjustments.

Ballbar testing:

Quickly checks servo performance and backlash, analyzing results to optimize servo parameters and reduce taper caused by servo lag or excessive backlash.

9. Conclusion

In CNC lathe machining, maintaining precision is the key to producing high-quality parts, and effectively addressing taper problems is an important part of this process. Accurate detection, root cause analysis, appropriate corrective measures, and preventive actions will ensure machining accuracy and quality.

If, after reading this article, you still cannot resolve the taper issue in your workpiece machining, feel free to contact our technical staff. Minnuo will provide you with professional solutions to support your production.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763