Machine Tool Selection Guide in the Context of Steel Industry Transformation

Nippon Steel has announced that after completing the acquisition of U.S. Steel, it will invest an additional $1.3 billion, focusing on upgrading high-grade steel production capacity and equipment systems. Although this is an industrial merger news, it reflects an important trend: steel companies are shifting from the traditional paradigm of controlling raw materials, building large blast furnaces, and reducing costs to emphasizing higher performance and stronger integration capabilities in core equipment, especially machine tool systems.

For the typical application needs of the steel industry, machine tool selection should focus on three major directions: mold parts require attention to five-axis linkage and precision control, large structural components emphasize stroke, torque, and load-bearing capacity, while mass repetitive processing tasks should prioritize automation collaboration efficiency.

This article will delve into this trend, analyze the critical role of machine tool systems in steel manufacturing, and provide a practical "Machine Tool Selection Guide" that focuses on selection logic, common pitfalls, and matching strategies for steel companies.

I. Machines Behind High-Grade Steel

1.Steel Product Upgrades and the Higher Precision Manufacturing Requirement

With the rapid development of emerging sectors like new energy vehicles, high-end equipment, and green buildings, traditional steel products can no longer meet increasingly complex performance requirements. Automotive-grade high-strength steel, corrosion-resistant stainless steel, electrical steel, and other "high-grade steels" have become the focus of competition among major steel manufacturers.Manufacturing these materials demands extremely high technical standards for processing equipment — from smelting and rolling to mold manufacturing and forming, each step requires higher processing precision and more stable system response.

2.High-End Machine Tools as the Key to Enhancing Steel Manufacturing Capability

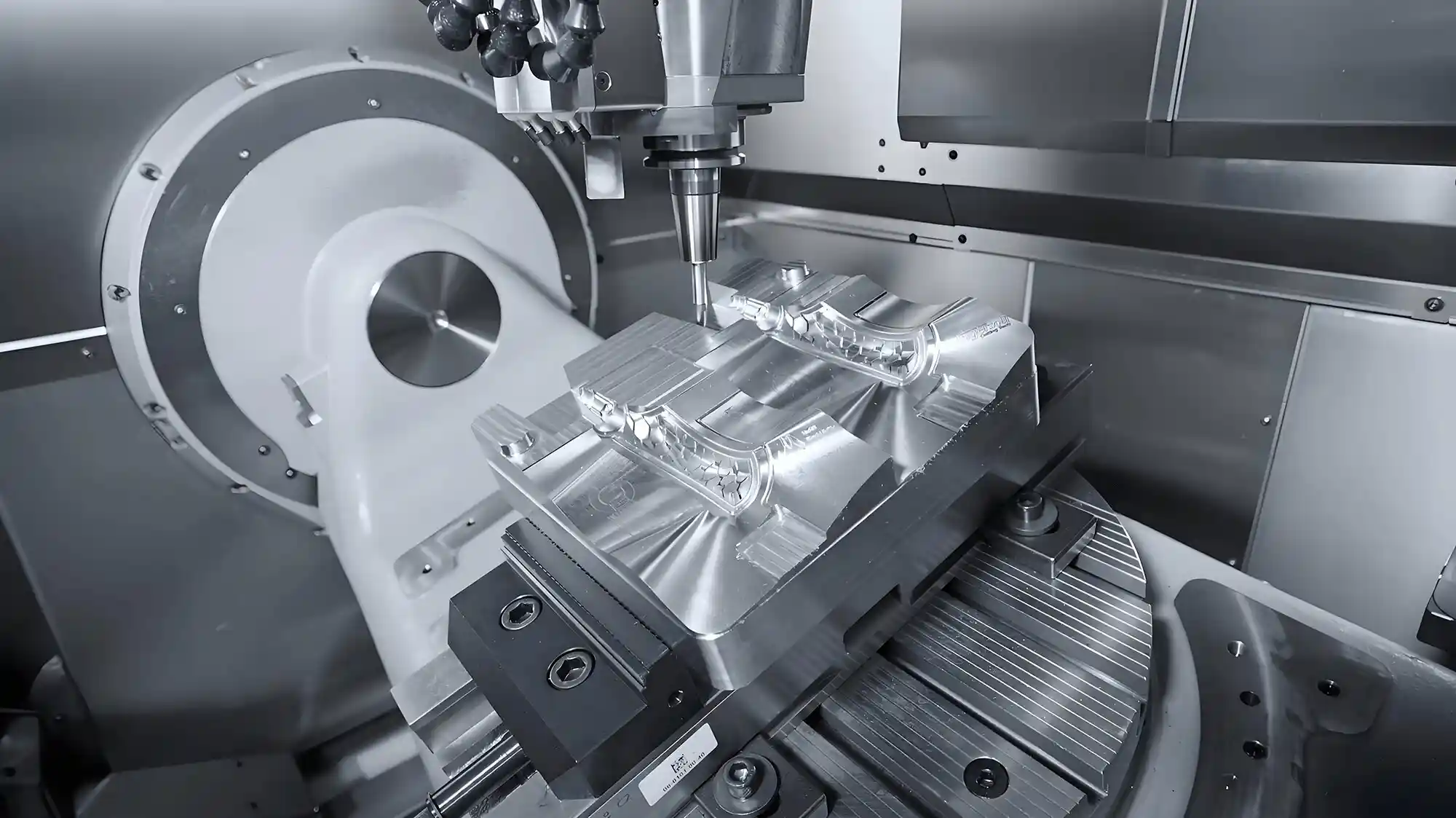

-Five-axis machining centers are the core equipment for machining complex geometries of mold steel.

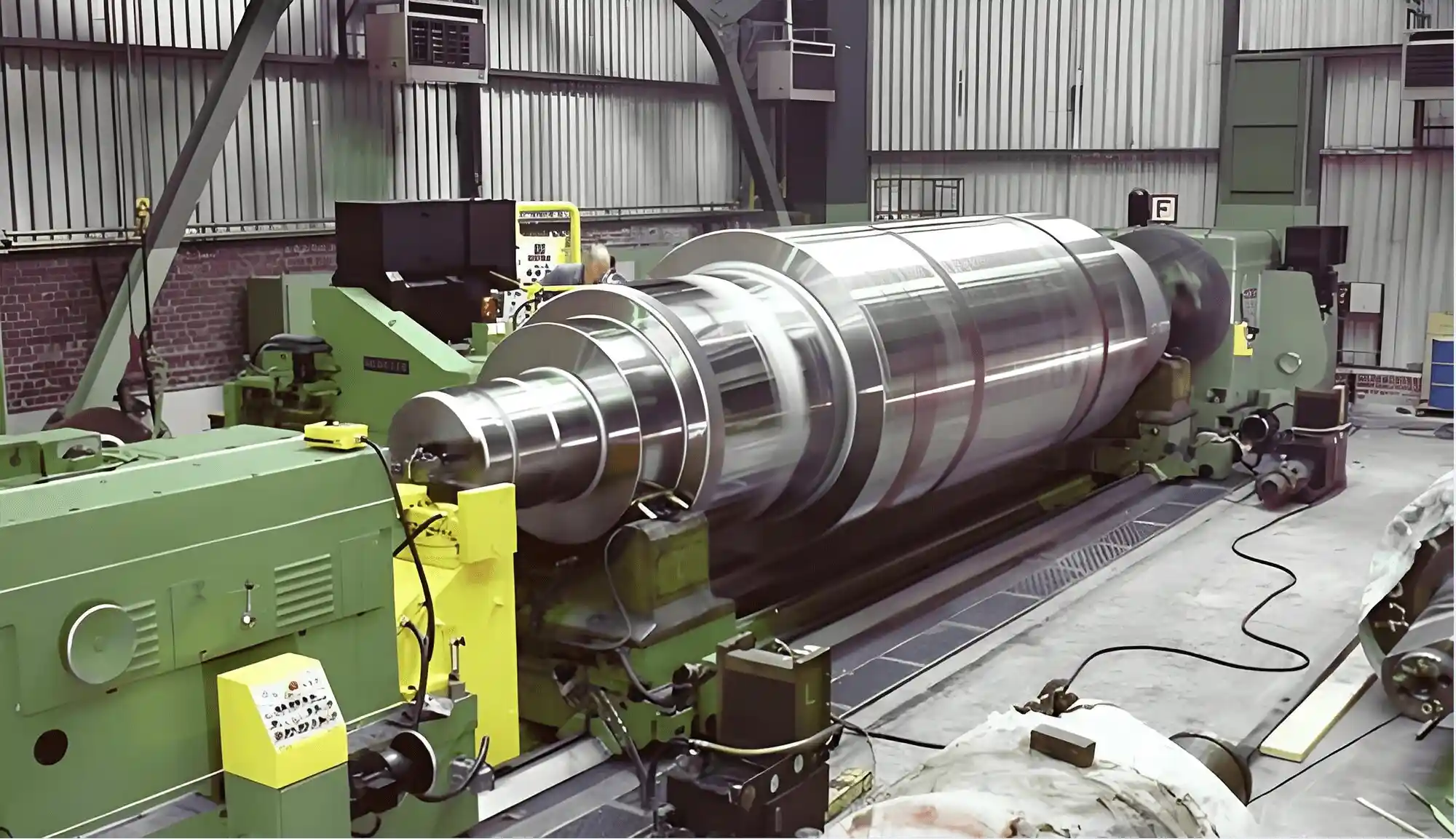

-CNC horizontal boring mills are the main machine types for processing large parts like rollers and furnace shells.

-Vertical lathes and heavy-duty gantry milling machines are essential in the finishing process of thick steel plates.

-Flexible manufacturing systems (FMS) + automatic loading and unloading serve as the infrastructure for efficient, high-consistency mass production.

Without the support of these machines, even the greatest investment in raw materials and funds will be futile.

II. User Selection: How Should Steel Manufacturers Choose Machine Tools?

Based on Nippon Steel's investment moves, we have summarized a machine tool selection logic for steel industry users:

▶ Application Scenario 1: Large Mold and Forming Parts Manufacturing

Key Indicators: Repeat positioning accuracy ≤ ±5μm; Spindle speed ≥ 12000rpm; Wide interference range

Applicable Fields: Automotive outer mold, electrical steel rolling mold, forming tools

Recommended Configuration: Coupled with automatic tool changers and probe systems to improve the machining efficiency of complex structures

▶ Application Scenario 2: Furnace Shell, Roller, and Other Structural Part Processing

Key Indicators: X/Y/Z travel ≥ 3 meters; Spindle torque ≥ 2000Nm; Load-bearing ≥ 15 tons

Applicable Fields: Smelting equipment cylinders, continuous casting equipment, metallurgical roller systems

Recommended Configuration: Equipped with high-rigidity worktables and real-time workpiece temperature monitoring systems

▶ Application Scenario 3: High Consistency Batch Production

Recommended Model: Horizontal machining center + Flexible manufacturing unit (FMS)Key Indicators: Tool change speed ≤ 2 seconds; Station switch time ≤ 15 seconds; MES system interface

Applicable Fields: High-grade steel structural part duplicate machining

Recommended Configuration: Automated loading, remote monitoring, and 24-hour unmanned systems

III. Three Major Pitfalls to Avoid in Machine Tool Selection

Although many steel companies have realized the importance of equipment upgrades, there are still common mistakes in the machine tool selection and procurement process, which affect production efficiency and return on investment.

1.Using "Price" Instead of "Fit"

Many users still tend to base their purchasing decisions solely on price, overlooking the equipment's stability and adaptability in real applications. As a result, they end up purchasing equipment that either has excessive specifications but unstable structures or is inexpensive but lacks support services, leading to increased long-term operational costs and even production line interruptions.

Recommendation: During the selection process, prioritize matching the process requirements, clarify the actual needs for positioning accuracy, rigidity, dynamic response, etc., and then consider budget and service capabilities.

2.Ignoring System Integration and Automation Compatibility

With the rise of flexible manufacturing and unmanned processing trends, selecting a single machine tool is no longer an isolated decision. Whether the equipment supports FMS, has MES interface capability, and is easy to expand in the future are key factors in system-level performance.

Recommendation: During the procurement phase, include "upstream and downstream interaction needs" in the overall planning, and deeply communicate interface specifications and expansion capabilities with the equipment supplier.

3.Over-Reliance on "Past Experience" and Overlooking "Material Changes"

Many companies continue to use past configurations to process new materials, such as using three-axis vertical machining to process high-strength mold steel and stainless steel shells. This results in long processing times, excessive tool wear, and fluctuating accuracy.

Recommendation: When dealing with high-grade steels and new materials, re-evaluate processing difficulty and choose CNC machines with high dynamic precision, rigid structures, and excellent process libraries.

Minnuo’s Technical Suggestions:

In our actual selection projects, we found that over 60% of production line issues arise not from equipment quality but from inadequate initial matching and blind selection of parameters. We recommend that companies conduct process validation testing at the early stages of selection and, if necessary, introduce digital twin simulations for layout rehearsals to minimize decision-making blind spots. Additionally, Minnuo provides high-level operation and maintenance support through the iNC-Cloud intelligent service platform. After each machine is connected to the cloud, the system can automatically push fault alerts, and remote engineers will respond promptly, ensuring that "equipment never stops, and service never ends." This helps customers minimize operational pressure and unplanned downtime risks.

IV. Conclusion

Nippon Steel’s actions are just the beginning. Over the next few years, the demand for high-grade steel will only continue to rise. Those who possess efficient, stable, and intelligent manufacturing equipment will take the lead in the market.

As equipment providers, we should closely follow this trend and provide customers with machine tool solutions that are not only "usable" but also "reliable," "durable," and "long-term dependable." Steel companies should also reassess machine tool selection from a strategic perspective, viewing equipment not just as a "cost" but as a "capability" and making it a core asset for competitive advantage.

If you are planning a production line upgrade or are confused about selecting machine tools for steel processing, feel free to contact Minnuo’s technical consulting team. We will provide you with a one-on-one customized solution, from selection evaluation, solution design, to delivery support and lifetime after-sales assistance, fully supporting your manufacturing upgrade.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763