Milling-turning machine tools: One-step clamping, multiple precision machining operations, unlocking a new paradigm for efficient production

In the workshop of a domestic automotive parts factory, the factory manager recently solved a problem that had plagued them for six months: previously, machining the transmission input shaft required rotating between three machines: a lathe, a milling machine, and a drilling machine. Workers would spend two hours setting up and debugging the machine, often resulting in misaligned coaxiality due to repeated positioning, resulting in a scrap rate as high as 8%. However, after switching to a milling-turning machine, the workpiece can be clamped once, and the entire process from blank to finished product can be completed in 25 minutes, with the scrap rate dropping to 1.2%. This reflects the current trend of many small and medium-sized manufacturers introducing milling-turning machines. "Precision machining multiple steps in a single clamping" is no longer the exclusive domain of high-end factories, but a practical solution that addresses the pain points of traditional machining and adapts to actual production needs. This article, drawing on real-world factory scenarios, analyzes the application value, common problems, and key selection criteria of milling-turning machines, helping companies avoid unnecessary mistakes.

Ⅰ. What is a milling machine? A versatile tool that can be used directly in the workshop

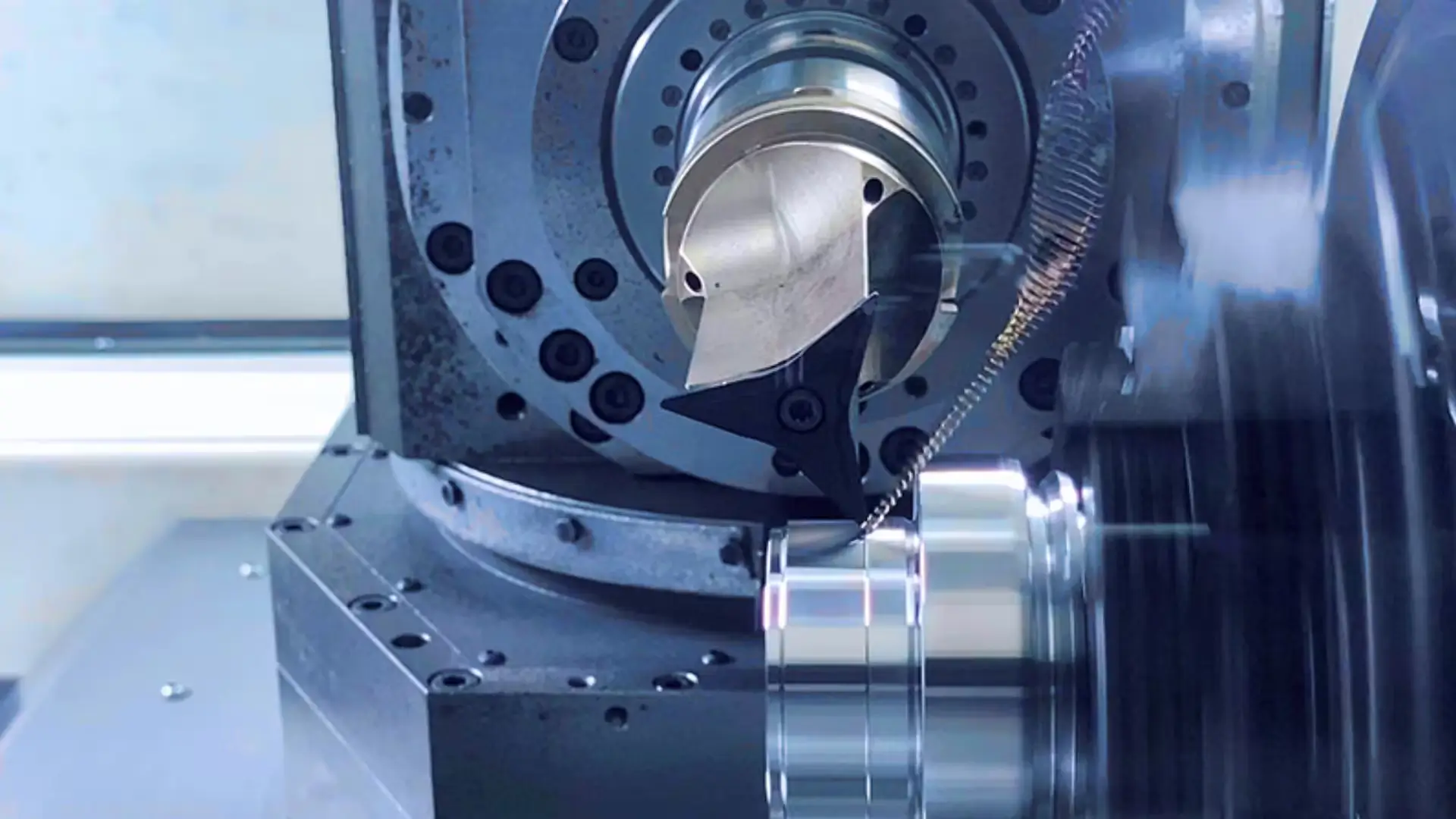

Many new bosses mistakenly believe that "turn-milling is just a lathe and milling machine combined," but those who have actually used it will realize that it is an "integrated machining center" that can be directly put into production. For example, a mold factory in Wuxi, Jiangsu uses a CK6150 turn-milling machine. After the workpiece is mounted on the spindle, it can use a turning tool to turn the external diameter and end face. After replacing the power turret, it can mill keyways, drill locating holes, and finally directly tap. The entire process does not require disassembly to change equipment. Workers only need to monitor the operation of the equipment, saving at least three manual steps compared to traditional processing.

From a practical perspective, the key configurations that support "one-time clamping, multiple processes" are actually these designs that can solve practical problems:

Dual-spindle design: When machining long shaft parts, the front spindle turns one end, and the rear spindle can directly take over to machine the other end, eliminating the need for manual workpiece flipping and avoiding bumps and positioning errors during flipping. For example, when machining a 1-meter-long motor shaft, the efficiency is 40% higher than with a single spindle.

Power turrets with 12 or more workstations: They can hold at least 12 different tools, ranging from turning tools and milling cutters to drills and taps. Tool changes are automatic during processing, eliminating the need for workers to frequently change tools manually. For example, when processing flanges with holes, tool change time is reduced from the traditional 5 minutes per change to 30 seconds per change.

Intuitive CNC system: Many factories have chosen the Fanuc 0i-TF system, which displays the machining trajectory directly on the screen. New users can learn by following the preset programs in just three days, eliminating the need for repeated debugging by experienced technicians like with traditional equipment.

Automatic chip conveyor: The iron chips generated during processing are automatically discharged to the chip collection box, without the need for workers to stop the machine from time to time to clean them. Especially when processing cast iron parts, it can prevent iron chips from scratching the workpiece surface and reduce rework.

(MINNUO High-Performance Mill and Turn Machine MNT50M)

Ⅱ. The actual value of a clamping: three accounts that workshop owners can calculate clearly

For factories, the ultimate consideration when selecting equipment is whether it can generate profits and reduce worry. The "one-time clamping" of a milling machine isn't just an abstract technical concept; it's a straightforward calculation of efficiency, precision, and cost.

1. Efficiency: Small and medium-sized batch production can cut cycle time in half

An agricultural machinery parts factory in Taizhou, Zhejiang, previously processed tractor transmission gear shafts for an order of 50 pieces. Traditionally, the process involved: turning on a lathe (one person per machine, 20 pieces per day) → keyway milling on a milling machine (one person per machine, 15 pieces per day) → drilling on a drilling machine (one person per machine, 18 pieces per day). Including waiting time, the 50 pieces took four days to complete. After switching to a milling machine, one person operated a single machine, and the machine could process 35 pieces per day, completing the 50 pieces in two days. This reduced the cycle time by 50% and saved two workers.

This is particularly suitable for the "multi-variety, small-batch" order characteristics of many factories today. For example, processing a motor shaft today and a flange tomorrow. When changing products, there is no need to change equipment. Only the program and tool need to be adjusted, and production can be switched within 1 hour. This is much more flexible than the traditional "one machine for one product" method.

2. Accuracy Account: Solving the problem of scrap caused by multiple clamping

A medical device factory in Qingdao, Shandong, previously processed artificial joint components. Because they required three clamping steps (turning, milling, and polishing), cumulative errors often resulted in dimensional deviations, leading to scrapped components costing over 2,000 yuan. After switching to a turning-milling machine, all steps were completed in a single clamping step, with errors controlled to within ±0.003mm. The scrap rate dropped from 7% to 0.8%, saving nearly 30,000 yuan per month.

Workshop technicians know that when clamping multiple times, even a 0.001mm deviation in the fixture can magnify the error in the final product. A milling machine is like "the workpiece is fixed, and the tool rotates around it," fundamentally eliminating clamping deviations. For example, a hydraulic valve core with high machining requirements can achieve a finish of Ra0.4μm, eliminating the need for subsequent polishing.

3. Cost Account: A cost-effective option for small and medium-sized factories to buy one unit for the price of three.

Many small and medium-sized factory owners worry that turning and milling machines are too expensive, but after calculating the overall cost, they realize they're a steal. For example, a hardware factory in Zhengzhou, Henan, previously spent 450,000 yuan each on a lathe, milling machine, and drilling machine, requiring three workers (each earning 8,000 yuan a month). They now have a VTC600 turning and milling machine (costing approximately 380,000 yuan), which can be operated by a single worker. This saves 70,000 yuan in equipment costs, 16,000 yuan in monthly labor costs, and an additional 192,000 yuan in annual profits.

It also takes up a small space, with one device taking up only 20 square meters, saving 25 square meters compared to three traditional devices (taking up 45 square meters). This makes it very practical for small factories with limited workshop space. Furthermore, it reduces the flow of workpieces, saves coordination time between work groups, and reduces management costs.

Ⅲ.Practical application scenarios: These industries use it most conveniently

Not all industries are suitable for turning and milling machine tools. Based on practical experience in the workshop, the following three types of industries can maximize their value:

1. Automotive parts: Batch processing of "multi-feature shaft parts"

Parts like engine crankshafts, transmission input shafts, and suspension connecting rods are often long and feature-rich (with external diameters, keyways, oil holes, and threads), requiring multiple setups for traditional machining. For example, an auto parts factory in Shiyan, Hubei, uses a CK6163 turning-milling machine to machine crankshafts. This allows them to complete turning the main journal, milling the balancing weights, and drilling the oil holes in a single setup. They can process 80 parts per day, 30 more than traditional methods, without having to worry about crankshaft vibration caused by balancing weight misalignment.

2. Hydraulic and pneumatic components: Solving the challenge of high-precision hole machining

Parts like hydraulic valve blocks and cylinder piston rods require not only high external diameter precision but also multiple holes drilled in different locations with stringent requirements for hole perpendicularity and coaxiality. A hydraulics factory in Suzhou, Jiangsu, uses a five-axis turning-milling machine to machine hydraulic valve blocks. This allows the machine to drill six holes in different directions in a single setup, with a verticality error of ≤0.005mm. This eliminates the previous "drilling the front first, then turning it over and drilling the back," improving efficiency by 60%.

3. Small and medium-volume hardware: meeting the needs of "multi-variety orders"

Many small factories producing custom hardware often receive orders in small batches of 10 or 20 pieces, making bearing sleeves one day and connecting shafts the next. The owner of a hardware factory in Wenzhou, Zhejiang, said, "Changing products used to require adjusting three machines. Now, with a milling machine, I can simply adjust the program and change the tool. For example, switching from machining a bearing sleeve (turning and drilling the inner hole) to machining a connecting shaft (turning and flattening) takes only 40 minutes, saving two hours. I can now confidently quote prices for small orders."

IV. Avoid pitfalls in model selection: 3 practical suggestions for small and medium-sized factories to avoid wasting money

Many factory owners regret buying a milling machine, not because the equipment is bad, but because they chose the wrong one. Based on the selection experience of over 100 small and medium-sized factories, we have three key points to keep in mind:

1. Don’t blindly pursue “high configuration”, choose according to “actual processing needs”

If you only want to process simple shaft parts (such as optical shafts and shafts with keyways), you can choose a "two-axis turning and milling machine" (such as CK6140), which costs about 250,000 to 350,000 yuan. There is no need to spend 500,000 yuan on a five-axis machine.

If you are processing complex curved parts (such as special-shaped joints), choose a five-axis machine model, but be sure to choose one with "RTCP function", otherwise it is easy to make mistakes when processing the curved surface;

You don't have to blindly pursue "±0.001mm" accuracy requirements. For most civilian parts (such as auto parts and hardware), "±0.005mm" accuracy is sufficient, which can save 100,000 to 150,000 yuan.

2. Always test the machine: Use your own workpiece for testing

Many manufacturers demonstrate machining using standard parts, but problems can arise when machining their own parts. For example, a machinery factory in Cangzhou, Hebei, failed to test a machine before purchasing it. When it purchased it, it discovered that the tool library was insufficient (only eight stations) for machining its own custom flanges. This meant that each machining process required tool changes midway, which was inefficient. They later upgraded to a 12-station model, which resolved the issue.

When testing the machine, it is best to bring your own factory's blanks and have the manufacturer process them on site to see: ① Is the processing time shorter than the traditional method; ② Can the finished product meet the precision standards; ③ Is the tool change smooth and the chip removal clean? Only buy if there are no problems with these.

3. After-sales service is more important than brand: choose a manufacturer with local service points

Milling machines are more complex than traditional equipment. If a problem arises, waiting for a repair from an out-of-town manufacturer can take anywhere from three days to a week, significantly impacting production. For example, a factory in Hefei, Anhui, previously purchased equipment from an out-of-town brand. When the spindle failed, the manufacturer's technicians took five days to come and repair it, resulting in five days of downtime and losses exceeding 100,000 yuan. They later switched to a brand with local service points, offering on-site repairs within 24 hours, offering greater peace of mind.

In addition, you should ask whether the manufacturer provides "operator training". Many workers in small factories have no experience with CNC equipment. If the manufacturer can send a trainer to provide on-site training for 3-5 days, workers will get started faster and avoid equipment damage due to improper operation.

Ⅴ. For small and medium-sized factories, it is a "tool for solving practical problems", not a "face-saving project"

Many small and medium-sized factory owners are buying turning and milling machines based on what others are buying, without really understanding whether they actually need them. In reality, these machines aren't synonymous with "high-end equipment," but rather practical tools that help factories address issues like low efficiency, poor precision, and high costs.

If your factory has these problems: ① machining parts requires more than two clampings; ② there are many small batch and multi-variety orders, and product changeovers are slow; ③ high precision requirements and multiple clampings lead to high scrap rates, then a turning-milling machine tool is likely to solve the problem; if you are only machining simple optical axes that can be completed in one clamping, then a traditional lathe is more cost-effective.

Choosing the right equipment is more important than buying expensive equipment. We hope this article will help small and medium-sized factory owners choose a milling machine that is profitable, easy to operate, and offers reliable after-sales service, tailored to their specific production needs. This will truly achieve "one-time setup, efficient production."

Email

Email sales1: +86 13295238763

sales1: +86 13295238763