How to choose a boring machine? 2025 CNC and ordinary boring machine purchase guide, avoid pitfalls to spend money

In the field of mechanical processing, boring machines serve as core equipment for achieving high-precision hole machining, directly determining product quality and production efficiency. However, when faced with a wide variety of CNC boring machines, conventional horizontal boring machines, and floor-standing boring machines available on the market, many procurement personnel and workshop owners find themselves in a dilemma: Should they choose CNC models or standard models? How can precision parameters be interpreted to avoid being misled? When budgets are limited, how to balance performance and costs?

Based on the actual needs of machining, this paper comprehensively disassembles the problems in the selection of boring machine, from the core preparation before purchase, key index judgment, different scenario model recommendation to avoid pitfalls, and helps you choose the "processing tool" suitable for production.

I. Before the selection of boring machine: 3 steps to clarify the core needs (avoid blindly following the trend)

The choice of a lathe is not "the more expensive, the better", but "the more suitable, the better". Three key questions can be identified before purchasing to greatly reduce the scope of selection and avoid buying "useless" or "insufficient" equipment.

1. Clarify processing requirements: reverse-engineer equipment capabilities from "workpiece"

The core function of boring machine is to process holes, end faces and threads, etc., which requires the equipment specification to be determined according to the specific parameters of the workpiece:

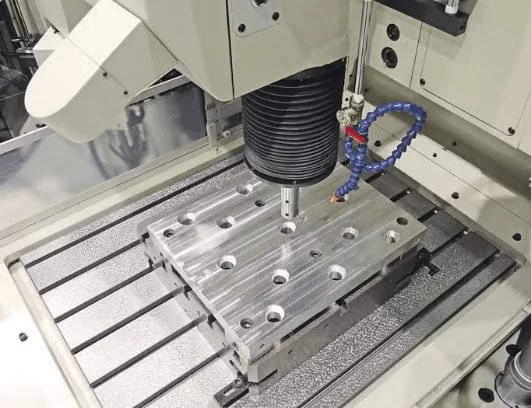

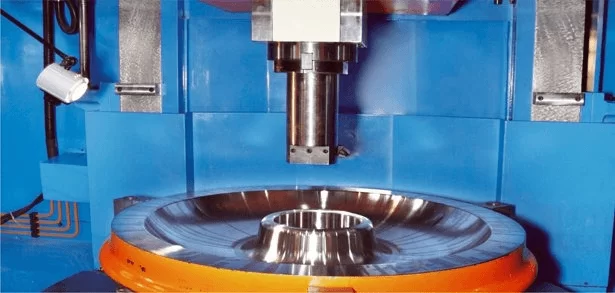

Workpiece dimensions: For processing large box-type components (e.g., machine tool beds, engine blocks), floor-standing boring machines or milling-boring machines are required. Their spindle travel (typically ≥1000mm) and load-bearing capacity (reaching several tons) enable large-scale machining. For small-to-medium workpieces (e.g., mold components, hydraulic valve blocks), horizontal boring machines (spindle travel 300-800mm) or CNC boring/milling machines offer greater flexibility and occupy less space.

Processing precision requirements: For general mechanical processing (e.g., standard bearing holes with IT7-IT8 grade accuracy), conventional horizontal boring machines are recommended for their cost-effectiveness. When handling precision molds or aerospace components requiring IT5-IT6 grade accuracy (with surface roughness ≤1.6μm), CNC boring machines must be selected, with particular attention to positioning accuracy (≤0.005mm/300mm) and repeat positioning accuracy (≤0.003mm).

Processing Batch Sizes and Complexity: Small-batch, multi-variety operations (e.g., custom-made components) can be handled by conventional boring machines with manual operation. For large-scale, complex-profile processing (such as mass-produced gearbox housings requiring continuous multi-station machining), CNC boring machines (particularly horizontal machining center-type boring machines with tool magazines) enable automated production through programming. This approach reduces manual intervention, enhancing both efficiency and consistency.

2. Determine the budget scope: different grades of equipment price difference is large

The price range of boring machine is very wide, ranging from hundreds of thousands to tens of millions. The equipment type should be locked according to the budget:

Economical (100,000 to 500,000 yuan): mainly based on ordinary horizontal boring machine, suitable for small processing workshops and start-up enterprises, meeting the basic hole processing needs, relying on manual operation, and the processing efficiency is medium.

Advanced (500,000 to 2 million yuan): covers economical CNC boring machine and vertical CNC boring and milling machine, with basic automation functions, can realize simple programming and processing, suitable for the precision machining scene of small and medium-sized enterprises.

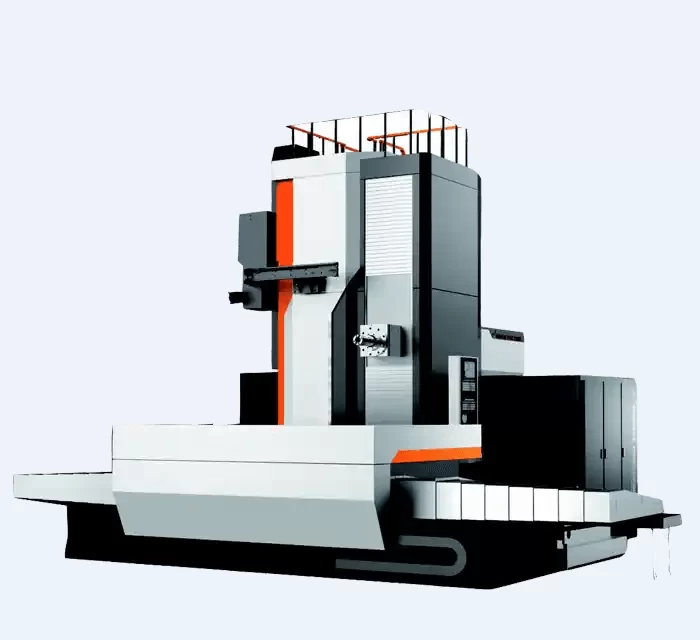

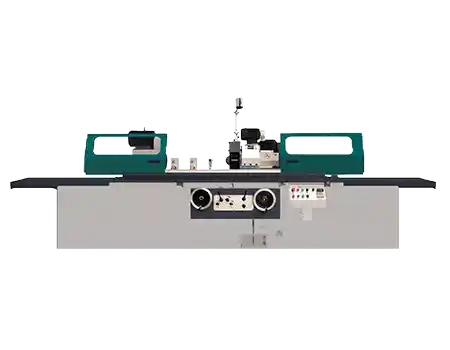

(Minnuo Horizon Boring Machine)

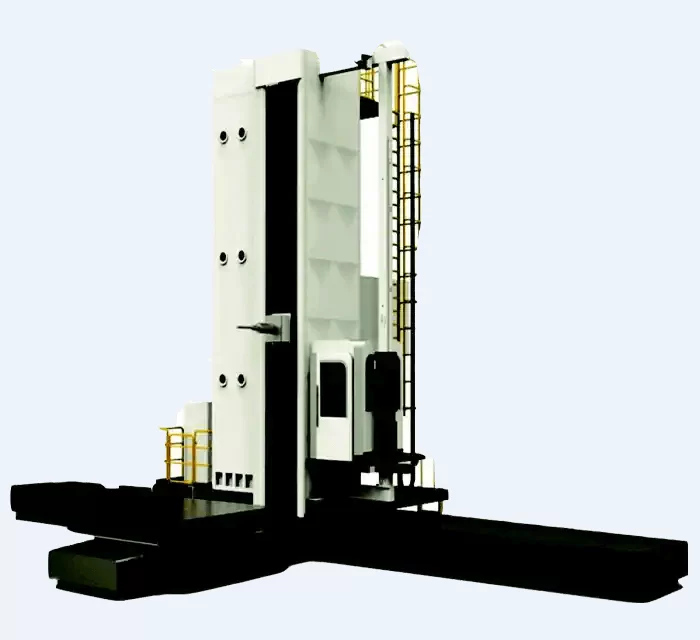

High-end (more than 2 million yuan): including high-precision CNC horizontal boring machine, floor milling boring machine, five-axis boring machine, etc., which are mainly used in large manufacturing enterprises, military and aerospace fields, and can meet the high-precision machining of complex curved surfaces and oversized workpieces.

3. Consider site and supporting conditions: avoid "affordable but unusable"

Site space: the floor boring machine is huge (the length and width are often more than 5 meters), so enough installation space should be reserved, and the ground should be reinforced (bearing capacity ≥5 tons /㎡); the horizontal boring machine occupies a small area (about 3-5㎡), which can be accommodated in ordinary factory buildings.

Power Supply and Supporting Systems: CNC boring machines require stable three-phase power (380V/50Hz). High-precision models with strict voltage stability requirements (fluctuation ≤±5%) must be equipped with voltage stabilizers. Additionally, if significant chip generation occurs during machining, the installation location of chip removal systems (e.g., chain-type chip collectors) should be planned in advance.

Operators' skills: Ordinary boring machine depends on the practical experience of technicians, and requires high skills of personnel; CNC boring machine requires operators to master programming (such as G code, M code) and equipment debugging skills. If the enterprise lacks relevant talents, it is necessary to arrange training in advance or choose manufacturers that can provide after-sales training.

II. Five core indicators: Teach you to understand the boring machine parameter table and avoid "wordplay"

Many purchasers are confused by the parameters of a boring machine (e.g., spindle speed, feed rate, positioning accuracy), and even misled by the manufacturer's "vague statements". The following 5 key indicators are the core of the performance of a boring machine, which should be paid attention to:

1. Spindle performance: determines processing efficiency and stability

The spindle is the "heart" of the boring machine, directly affecting the precision and surface quality of hole machining:

Spindle speed specifications: Conventional horizontal boring machines typically operate at 50-1500 rpm, suitable for machining standard materials like cast iron and steel. CNC boring machines feature higher speeds (3000-6000 rpm), which, when paired with high-speed cutting tools, enable processing of difficult-to-machine materials such as aluminum alloys andtitanium alloys, significantly improving efficiency. Important note: The "maximum speed" indicated by manufacturers should be verified as "continuous stable speed". Some products may display "instantaneous maximum speed", but these values are often unattainable in practical applications.

Spindle bore diameter: A larger spindle bore allows for thicker tool shank diameters, providing enhanced rigidity during machining of large-diameter holes. For example, boring machines with spindles ≥80mm are required for holes ≥100mm in diameter, while smaller bore sizes (≤50mm) can be processed effectively using spindles with 50-60mm diameters.

Spindle rigidity: The maximum output torque of the spindle (unit: N·m) determines its rigidity. Higher torque means greater rigidity, which reduces vibration during machining (especially for deep hole machining). Conventional boring machines typically have a torque of 200-500 N·m, while CNC floor boring machines can achieve over 1000 N·m.

2. Positioning accuracy and repeated positioning accuracy: the "hard indicator" of accuracy

These two parameters directly determine the "accuracy" of boring machine processing, and are the core assessment standards of precision machining:

Positioning accuracy: This refers to the deviation between the actual distance traveled by a machine tool's spindle from one position to another and the theoretical distance. A smaller deviation indicates higher precision. For example, the specification "Positioning accuracy ≤0.008mm/1000mm" means the spindle's movement within 1000mm should have a maximum deviation of no more than 0.008mm. While conventional boring machines typically achieve 0.02-0.05mm/1000mm positioning accuracy, CNC boring machines must meet 0.005-0.01mm/1000mm precision standards (precision grade).

Repeat positioning accuracy: refers to the maximum deviation of the actual position when the spindle moves to the same position for many times, reflecting the stability of the equipment. Repeat positioning accuracy is usually 1/2-1/3 of the positioning accuracy. For example, the repeat positioning accuracy of a CNC boring machine with positioning accuracy of 0.008mm should be ≤0.004mm.

Avoid pitfall: some manufacturers will mark the "factory precision", but in actual use, the precision may be reduced due to installation and ambient temperature. When purchasing, you can ask the manufacturer to provide the "precision test report after on-site installation", and agree on the after-sales solution for the precision attenuation during the warranty period.

3. Feed system: affects machining efficiency and surface roughness

The feed system controls the moving speed of the worktable or spindle, which is divided into manual feed (ordinary boring machine) and servo feed (numerical control boring machine):

Feed speed: In conventional boring machines, manual feed speed control by operators results in low efficiency and inconsistent performance. CNC boring machines feature adjustable servo feed speeds (typically 5-1000mm/min), with high-speed feeds (≥500mm/min) ideal for rough machining and low-speed feeds (≤50mm/min) for finish machining. This design reduces tool wear while improving surface roughness (Ra value can be reduced below 0.8μm).

Feed Motor Types: CNC boring machine feed motors are categorized into "stepper motors" and "servo motors". Stepper motors, while cost-effective, are prone to "step loss" during high-speed operation (causing machining errors), making them suitable only for budget CNC boring machines. Servo motors (such as Mitsubishi and FANUC servo systems) offer rapid response and precise positioning, serving as standard equipment for mid-to-high-end CNC boring machines. When purchasing, ensure to confirm the motor brand and model specifications.

4. Machine tool structure and material: determine stability and service life

The "skeleton" of the boring machine directly affects the stability of long-term use, so we need to pay attention to the material and structure of core components such as the bed and columns:

Bed Material Selection: High-strength cast iron (e.g., HT300)is the preferred choice, offering superior vibration damping and wear resistance compared to regular cast iron. Some high-end models employ a "cast iron + resin sand molding" process to reduce internal stress, ensuring long-term stability without deformation. Avoid "welded steel plate beds" (suitable only for small-scale portable boring machines), as their poor rigidity and stability may lead to precision drift over extended use.

Structural design: Horizontal boring machine should pay attention to "spindle box balance device" (such as weight balance or hydraulic balance) to reduce the vibration of spindle moving up and down; floor boring machine should check "beam locking mechanism" to ensure that the beam does not shake during processing (especially when processing large workpieces).

5. Supporting systems and accessories: improved processing convenience

Reasonable supporting systems can greatly improve processing efficiency. When purchasing, it is necessary to confirm according to the requirements:

Tool magazine capacity: the tool magazine capacity of CNC boring machine (especially machining center type) determines the continuous processing capacity. For small batch processing, a tool magazine with 16-24 tools can be selected, and for large batch complex processing, a tool magazine with 32-64 tools can be used to reduce the number of tool changes.

Cooling System: Deep hole machining (hole depth ≥5 times hole diameter) requires an "internal cooling system" (coolant flows through the tool holder to reach the cutting area), while shallow hole machining can use an "external cooling system". Additionally, ensure the cooling pump's flow rate is ≥50L/min, as insufficient flow may cause tool overheating and affect machining accuracy.

Measurement system: Precision machining It is recommended to choose a CNC boring machine with "grating scale" to realize real-time position detection and compensation, and further improve the positioning accuracy; economical CNC boring machine mostly uses "encoder", which has relatively low precision but lower cost.

III. Recommended boring machine for different scenarios: match according to needs and maximize cost performance

Combined with the processing requirements, budget and site conditions, the following are three types of boring table selection schemes for common scenarios, which can be directly referenced:

1. Small workshops/Start-ups: basic processing, cost-effectiveness is a priority

Core requirements: small batch, small and medium size workpieces (such as bearing seat, flange), precision requirements IT7-IT8 grade, limited budget (100,000 to 300,000).

Recommended model: ordinary horizontal boring machine.

Advantages: simple structure, low operation threshold, low maintenance cost; spindle speed 50-1200r/min, spindle diameter 50-60mm, can meet the needs of conventional hole processing, end milling; floor space only 3-4㎡, ordinary plant can be installed.

Note: It needs to be equipped with skilled technicians, and the processing efficiency is medium, which is not suitable for complex contours and mass production.

2. Small and medium-sized manufacturing enterprises: precision machining + mass production

Core requirements: medium-sized workpieces (such as hydraulic valve block, motor housing), precision requirements IT6-IT7, batch production (daily output of 50-100 pieces), budget of 500,000 to 1.5 million yuan.

Recommended model: economical CNC horizontal boring machine.

Advantages:

Equipped with FANUC or Siemens basic CNC systems that support manual programming and CAD/CAM automatic programming; featuring positioning accuracy of 0.01mm/1000mm and repeat positioning accuracy of 0.005mm, capable of machining complex hole systems, threads, and planar contours. Some models come with 16-24 tool magazines for automatic tool change, boosting processing efficiency by 30%-50% compared to conventional boring machines.

Applicable scenarios: batch processing of auto parts, construction machinery parts, etc., which can be combined with automatic feeding mechanism to further improve the level of automation.

3. Large enterprises/ precision manufacturing: complex, oversized machining

Core requirements: large boxes, heavy parts (such as machine tool bed, wind power gearbox), precision requirements IT5-IT6, need to process deep holes, complex surfaces, budget more than 2 million yuan.

Recommended model: CNC floor milling and boring machine.

Key Advantages: The spindle has a travel range of ≥2000mm and can handle loads of 5-20 tons, enabling processing of large workpieces over 3 meters in length. Equipped with high-precision linear guides and a five-axis linkage system, it achieves multi-angle and complex surface machining (e.g., aviation engine casings). With spindle torque ≥1000N·m, the machine ensures stable rigidity during deep-hole machining (hole depth ≥10 times diameter), delivering surface roughness as low as Ra0.8μm.

Suggested accessories: plant layout should be planned in advance (reserve lifting equipment location), special foundation and constant temperature system (temperature fluctuation ≤±2℃) should be provided to avoid environmental impact on processing precision.

IV. Boring machine selection guide: 80% of purchasers will fall into the four minefields

1. Look only at the "parameter table" and ignore the "field test"

Many buyers evaluate equipment performance solely based on manufacturer-provided specifications, overlooking the critical importance of field testing. Key recommendations: When conducting tests, bring your own typical workpieces (e.g., components with complex hole systems). After processing them on-site, measure precision using dial indicators and surface roughness testers. Simultaneously monitor operational noise levels (normal values should not exceed 75 dB) and spindle vibration conditions. This approach helps avoid purchasing products that are "visually appealing in specs but underperforming in reality."

2.Blindly pursuing "numerical control" at the expense of their own needs

Some manufacturers assume "numerical control (NC) boring machines must outperform conventional models," but when processing simple hole systems for small-batch production, their exorbitant price tag (3-5 times higher than standard models) and operational complexity become significant burdens. For instance, when machining standardized flanges requiring only boring and end face milling, conventional boring machines using specialized tooling can achieve higher efficiency and lower costs compared to NC equipment.

3. Neglect "after-sales service" and high cost of later maintenance

Boring machine is a large equipment, and the maintenance (such as spindle maintenance and CNC system debugging) depends on the manufacturer's support. When purchasing, it is necessary to confirm:

Warranty period: The warranty period of core components (spindle, bed and CNC system) should be at least 1 year, and the warranty period of the whole machine should be at least 6 months;

After-sales response time: whether to provide door-to-door service within 48 hours (especially in remote areas);

Supplies: Whether the wear parts (such as guide rail slider, bearing) are in stock, and the supply cycle is less than 7 days.

Avoid choosing "small workshop manufacturers", which may lack spare parts inventory and professional after-sales team, equipment problems are difficult to repair, resulting in downtime losses.

4. Ignore "energy consumption and environmental protection" and long-term costs exceed expectations

Conventional boring machines operate with relatively low energy consumption (5-10 kW), whereas CNC boring machines (particularly floor-standing models) can reach 20-50kW power output, resulting in higher long-term electricity costs. Additionally, the chips and coolant waste generated during machining must meet environmental protection standards. When purchasing equipment, buyers should verify whether it is equipped with oil mist separators (to reduce fume pollution) and liquid recovery systems to avoid penalties from environmental authorities.

V. Summary: The "3-step decision method" for the selection of boring machine

Determine the demand: according to the size (large/medium/small), precision (IT5-IT8 grade) and batch (single/many batches) of the workpiece, determine whether to choose a general boring machine or a CNC boring machine, and lock the equipment type;

Focus on the core: focus on checking spindle performance (speed, aperture, torque), precision parameters (positioning/repeated positioning accuracy), bed material, and eliminate products with non-compliant parameters;

Compare details: compare prices, after-sales service, energy consumption, environmental protection facilities, and give priority to the model that "fits the parameters + perfect after-sales service + controllable long-term cost", rather than simply pursuing "high price and high-end".

By following these proven strategies, you can avoid 90% of common pitfalls in equipment selection and choose boring machine tools that not only meet current production needs but also support future capacity upgrades. If you're still unsure about the right model, feel free to share your machining parameters, budget, and facility conditions in the comments section – we'll provide tailored recommendations based on your specific requirements.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763