Precision Deterioration Prevention Manual for Vertical Machining Centers: A Comprehensive Practical Guide from Daily Cleaning to Annual Calibration | Repeatability Stability ±0.003mm

In manufacturing production, precision degradation in vertical machining centers poses a critical risk to part quality and production efficiency. At best, it drives up scrap rates; at worst, it accelerates equipment depreciation. This article focuses on the core issue of precision maintenance for vertical machining centers, presenting a comprehensive, hands-on approach to preventing accuracy loss—from daily cleaning and guideway lubrication to laser interferometer calibration. It empowers workshops to stabilize machining precision and reduce costs.

Are you struggling with high scrap rates caused by accuracy degradation in your vertical machining center? Don't worry. This guide not only details critical daily cleaning steps, lubricant selection for guideways, and operational essentials but also shares practical laser interferometer calibration procedures. It includes accuracy warning standards for equipment of varying service lives, helping you maintain repeat positioning accuracy within ±0.003mm and effectively extend equipment precision lifespan by 30%.

These methods aren't theoretical concepts—they're proven, actionable techniques validated across numerous workshops. From daily 10-minute cleaning routines to annual calibration protocols, each step includes specific operational guidelines and tool recommendations. Continue reading to master the core secrets for maintaining long-term precision in vertical machining centers, safeguarding both production efficiency and product quality.

I. Why is Accuracy Degradation the Workshop's “Invisible Profit Killer”?

1. Three Direct Losses from Accuracy Degradation

Increased Scrap Rate: For machining a φ50mm precision shaft, a repeat positioning accuracy drop from ±0.005mm to ±0.01mm raises scrap rate from 2% to 8%, resulting in over ¥12,000 monthly losses.

Increased Rework Costs: Parts exceeding tolerances require secondary processing, with average rework time per piece increasing by 15 minutes, wasting 2.5 hours of labor time daily;

Accelerated Equipment Depreciation: Failure to prevent accuracy degradation may shorten a machine's 5-year precision lifespan to just 3 years, prematurely initiating its “countdown to obsolescence.”

2. Four Core Causes of Precision Degradation in Vertical Machining Centers

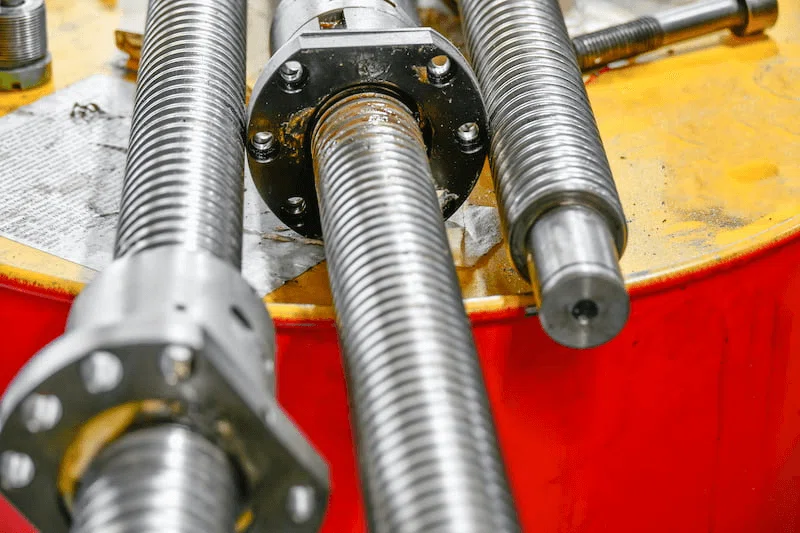

Contaminated/Worn Guideways/Leadscrews: Chip and coolant residue entering guideway gaps increases sliding resistance and accumulates positioning errors;

Spindle Taper Hole Misalignment: Wear or contaminants on tool holder/taper interface cause tool runout (up to 0.008mm);

Lubrication Failure: Degraded or insufficient guideway/lead screw oil causes dry friction, accelerating component wear;

Accumulated Thermal Deformation: Untreated thermal distortion in the spindle and bed after prolonged operation shifts precision benchmarks.

3.Precision Warning Standards for Equipment of Different Service Lifespans

| Service Life | Repeatability Warning Threshold | Typical Symptoms | Response Priority |

|---|---|---|---|

| 1–3 years (New) | > ±0.005 mm | Occasional dimensional out-of-tolerance parts; surface roughness variation | Medium (inspect within 2 weeks) |

| 3–5 years (Mature) | > ±0.008 mm | Dimensional drift in batch production; accuracy deviation after tool changes | High (resolve within 1 week) |

| Over 5 years (Aging) | > ±0.012 mm | Frequent tolerance failures; accuracy reverts shortly after calibration | Critical (intervene within 3 days) |

II. Basic Defense: Daily Cleaning — 10 Minutes a Day to Block the Source of Precision Decline

1. Guide Rail Cleaning: 3 Steps to Eliminate “Hidden Wear Sources”

Tools Required: Lint-free cloth, specialized guide rail cleaner (e.g., WD-40 Machine Tool Formula), scraper;

Procedure:

Manually move the axis to both ends of its travel. Use the scraper to remove accumulated chips inside the guide rail cover (focus on cleaning the guide rail grooves).

Spray cleaner onto the guide rail surface. Wipe along the rail direction with a lint-free cloth (avoid back-and-forth motion to prevent debris from scratching the rail).

After cleaning, manually move the axis 2-3 times to confirm smooth operation without sticking. Then replenish guide rail oil.

Critical Reminder: Enhanced cleaning is required after machining aluminum or cast iron parts. Aluminum chips readily oxidize and adhere to rails, while cast iron chips' high hardness can scratch surfaces.

2. Spindle Taper Hole Cleaning: Critical for Avoiding “Millimeter-Level Errors”

Contamination Hazards: Residual chips/oil in taper holes cause tool holder runout, exceeding hole coaxiality tolerances (e.g., φ10mm hole coaxiality increases from 0.005mm to 0.015mm);

Cleaning Procedure:

After spindle stops, blow out loose dust from the taper hole using compressed air (0.4-0.6MPa pressure);

Wrap a dedicated taper hole cleaning rod with an alcohol-soaked lint-free cloth, insert into the taper hole, and rotate to wipe 3 times (avoid contact with the spindle end face sensor);

Before installing the tool holder, clean its taper surface using the same method to ensure the mating surface is free of contaminants.

Frequency requirement: Clean once after every 5 tool holder changes or after machining 10 parts.

3. Cleaning of Lead Screw Guards and Sensors

Lead Screw Guards: Weekly, use a soft brush to remove chips from the folds of the guard and inspect for damage (damage allows chips to enter the lead screw, accelerating wear).

Linear Scale /Encoder: Monthly wipe the scale reading head with a lint-free cloth dampened in specialized cleaner to prevent coolant splashes (contamination causes positioning accuracy fluctuations).

III. Critical Maintenance: Regular Lubrication — Extending Precision Component Lifespan

1. Lubricant Selection: Choosing the right oil reduces wear by 50%.

| Lubrication Point | Recommended Oil Model | Viscosity Requirement | Replacement Interval |

|---|---|---|---|

| Linear Guideways | Mobil SHC Cibus 32 or equivalent guideway oil | 30–40 cSt @ 40°C | New machine: every 3 months |

Used machine: every 2 months | |||

| Ball Screws | Shell Omala S2 G 68 or equivalent gear oil | 65–75 cSt @ 40°C | New machine: every 6 months |

Used machine: every 4 months | |||

| Spindle Bearings | Castrol Hyspin AWS 46 or equivalent hydraulic oil | 45–50 cSt @ 40°C | Once a year (or every 2,000 hours of operation) |

2. The “Three Precisions” of Lubrication Operations

Precise Oil Volume: Apply 0.5-1ml of oil per meter of guide rail travel (excessive oil causes splattering and attracts chips); lubricate lead screws as specified in the manual, typically 5-8ml per application.

Timing Precision: Set automatic lubrication intervals (e.g., lubricate every 30 minutes of operation for 2 seconds per cycle) to prevent dry running;

Location Precision: Ensure lubricant reaches friction surfaces directly (e.g., guide rail oil must be injected into grooves, not applied superficially). Verify lubrication effectiveness via oil sight glasses.

3. Emergency Response to Lubrication Failure

If abnormal noise (e.g., squeaking) occurs on guideways/lead screws, immediately shut down for inspection;

For minor wear caused by oil deficiency, clean components first, apply specialized repair agents (e.g., SKF bearing repair compound), then resume lubrication;

For severe wear (e.g., scratches on guideway surfaces), contact the manufacturer for part replacement to prevent further accuracy degradation.

IV. Precision Reset: Annual Calibration — Restoring “Out-of-Tolerance Precision” with Professional Tools

1. Three Preparations Before Calibration

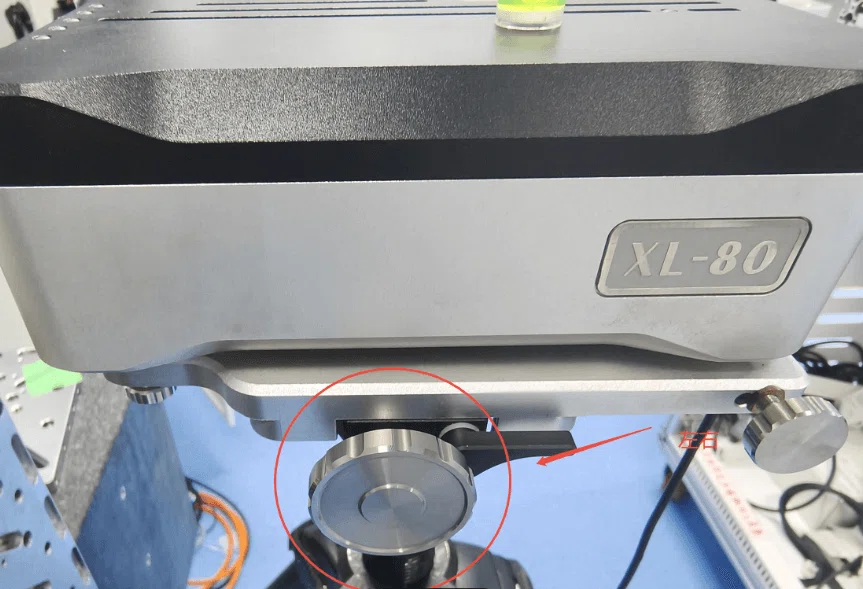

Tooling: Laser interferometer (e.g., Renishaw XL-80, accuracy ±0.5ppm), ball bar tester, leveling gauge (accuracy 0.02mm/m);

Environmental Preparation: Direct airflow from workshop air conditioning must be avoided. Ensure stable ambient temperature (20±2°C). Preheat equipment for 2 hours (to stabilize thermal deformation).

Part Preparation: Machine one standard test piece (e.g., 100×100×20mm rectangular block with flat surfaces, holes, and steps) for post-calibration accuracy verification.

2. Five-Step Laser Interferometer Calibration Procedure

Install laser head and reflector: Secure the laser head to the machine bed and the reflector to the spindle or worktable, ensuring optical path alignment.

Set calibration parameters: Input machine model, axis travel, and measurement point density (one point per 50mm), then select “Positioning Accuracy” and “Repeatability Accuracy” measurement modes.

Automatic Measurement: Initiate the machine tool's automatic operation program; the laser interferometer records real-time error data at each point;

Data Processing: Analyze data using dedicated software (e.g., Renishaw Laser10) to generate error curves and identify out-of-tolerance intervals (e.g., X-axis error of -0.007mm at 300mm);

Accuracy Compensation: Input error data into machine tool parameters (e.g., FANUC system parameter 1815, Siemens system MD32700). Restart the machine tool after completing compensation.

3. Calibration Accuracy Verification

Test Cutting Verification: Process standard test pieces, measuring flatness (≤0.003mm), hole position accuracy (≤0.005mm), and step dimension tolerance (±0.002mm);

Ballbar Inspection: Test machine dynamic accuracy (e.g., roundness error ≤0.004mm) via ballbar to confirm feed system backlash-free;

Continuous Production Validation: Process 10-20 parts in small batches, monitor dimensional consistency, ensuring repeat positioning accuracy remains stable within ±0.003mm.

V. Special Scenarios: Precision Emergency Solutions — Addressing Sudden Deviations

1. 5-Minute Troubleshooting for Sudden Deviations During Machining

Check if the tool holder is loose (re-tighten the holder to the specified torque, e.g., BT40 holder torque: 80-100 N・m);

Clean the spindle taper hole and tool holder taper surface to eliminate poor contact issues;

Manually move the axes to detect any binding (indicating debris on the guideways/lead screws);

Check lubrication system for alarms (oil shortage causes accuracy fluctuations);

Measure ambient temperature for sudden spikes/drops (e.g., air conditioner activation).

2. Precision Restoration Techniques for Aging Equipment

Minor guide rail wear: Apply “plastic coating” restoration (0.1-0.2mm thickness) to restore clearance;

Excessive ball screw backlash: Compensate via machine parameters (e.g., FANUC parameter 1851—input backlash value), with single compensation ≤0.005mm;

Spindle thermal deformation: Install a temperature sensor at the spindle front and enable dynamic thermal compensation (e.g., set parameter 3750 to 1) to offset thermal elongation errors.

FAQ: Workshop's Top Precision Maintenance Concerns

Q1: Is spending 10 minutes daily on routine cleaning worthwhile? A: Absolutely! A precision parts manufacturer reported that consistent daily cleaning reduced guideway wear by 40%, extended precision lifespan from 3 to 4.5 years, and cut annual component replacement costs by ¥23,000.

Q2: How can I perform a simple accuracy calibration without a laser interferometer? A: Use the “Standard Bar Comparison Method”: Measure the diameter of a standard bar (e.g., φ50×300mm) with accuracy ≤0.001mm at different positions on the machine tool. Calculate the deviation values and manually adjust the compensation parameters (suitable for emergencies, though less accurate than a laser interferometer).

Q3: Do new machines require annual calibration? A: Yes! After one year of operation, the bed and guideways may experience slight deformation. Calibration optimizes initial precision (e.g., ±0.004mm) to ±0.003mm, establishing a foundation for subsequent machining.

Q4: Are there precision maintenance differences when machining aluminum and steel parts? A: Yes! Aluminum chips oxidize and stick easily, requiring enhanced guideway/spindle cleaning (clean after every 5 parts). Steel parts involve higher cutting forces, necessitating focused checks on lubrication and spindle rigidity to prevent component overload and wear.

Conclusion

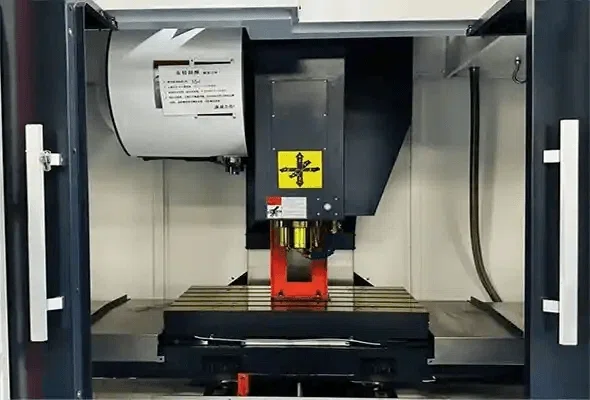

Precision degradation in vertical machining centers is a gradual process. The three-step approach—daily cleaning to block contamination sources, regular lubrication to delay wear, and annual calibration to reset accuracy—is key to maintaining repeat positioning accuracy within ±0.003mm and extending equipment precision lifespan by over 30%. MINNUO vertical machining centers incorporate precision-preserving design from the outset: The spindle taper hole undergoes ultra-precision grinding, paired with a proprietary taper hole cleaning solution, to sustain long-term runout within ≤0.002mm.

For lubrication and calibration,MINNUO machinesfeature an intelligent adaptive lubrication system that automatically adjusts oil volume and lubrication intervals based on machining load and ambient temperature, eliminating human maintenance errors and oversights. Additionally, the machine's high-precision calibration interface and standardized parameter system seamlessly integrate with laser interferometer calibration processes, significantly reducing the difficulty and time required for accuracy reset. These design and technological advantages enable workshops to implement precision maintenance measures more efficiently, further amplifying the precision retention effects of the “Three-Step Method.”

To ensure your vertical machining center maintains optimal precision long-term, start today by inspecting your equipment according to the “Daily Cleaning” steps outlined in this article. Optimize your maintenance workflow by combining these practices with MINNUO's complimentary “Exclusive Cleaning and Lubrication Guide” (available upon contacting customer service). Additionally, remember to schedule laser interferometer calibration through MINNUO's nationwide professional calibration service network when your equipment reaches one year of operation. MINNUO is committed to being your reliable partner for stable workshop precision, cost reduction, and efficiency gains through professional machine tool design and full-cycle service support.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763