The Ultimate Guide to What is a CNC Machine

CNC machines are now ubiquitous in modern manufacturing—they are crucial in industries such as aerospace, automotive, electronics, and more. These machines have drastically changed the way we design, prototype, and manufacture products, offering unmatched precision, efficiency, and flexibility.

CNC (Computer Numerical Control) technology is a sophisticated tool that utilizes computer programming to control machinery. With its ability to perform tasks such as cutting, drilling, and milling, CNC machines ensure high accuracy and repeatability. Understanding CNC machines is essential for professionals in modern manufacturing, as they significantly improve production efficiency and product quality.

Want to learn more about CNC machines and how they are transforming manufacturing? Read on!

I.A Brief History of CNC Machine Tools

CNC machines have been pivotal in revolutionizing manufacturing processes since their inception in the mid-20th century. Prior to CNC, manual machining was the norm, where skilled operators controlled the machines using handwheels and levers. This was not only time-consuming but also prone to human error.

The idea for automated control emerged during World War II, when manufacturing processes needed to be more precise and efficient. In the late 1940s, John T. Parsons developed the first numerical control (NC) machine, using punched cards to control machine movements. This breakthrough laid the foundation for CNC technology.

In the 1950s, MIT partnered with the U.S. Air Force to create the first true CNC machine. By using a computer to control the tool paths, CNC technology enabled complex and precise machining. This transformation drastically improved manufacturing accuracy, repeatability, and automation.

II.What is CNC?

CNC stands for Computer Numerical Control. It involves the automated control of machining tools via a computer. A CNC machine reads a digital file containing instructions (known as G-code) that direct the machine’s movements, including speed, path, and feed rate.

Key components of a CNC system include:

Computer: The brain that runs specialized software to interpret the instructions.

Controller: The interface between the computer and the machine, converting instructions into signals that control machine operations.

Drive Motors: These move the machine’s components along the X, Y, and Z axes and rotate the spindle.

Machine Tool: The part that does the actual machining—whether it’s cutting, drilling, milling, etc.

CNC technology is critical for achieving high precision and repeatability, which is why it’s foundational in modern manufacturing.

III.What is a CNC Machine?

A CNC machine is an automated tool controlled by a computer. These machines perform a variety of functions, including cutting, drilling, milling, turning, and more. Different CNC machines are designed for specific tasks and materials.

Here’s how a CNC machine works:

Design the Part: Use CAD software to create a digital model of the part.

Generate the CNC Program: Convert the CAD model into G-code using CAM software.

Load the Program: Transfer the CNC program to the machine’s controller.

Set Up the Machine: Install the appropriate tools, secure the workpiece, and configure machine settings.

Run the Program: The controller directs the machine tool to follow the programmed path and perform the desired machining operations.

IV.Main CNC Machine Functions:

Cutting: Removing material to create a shape.

Drilling: Creating holes in the workpiece.

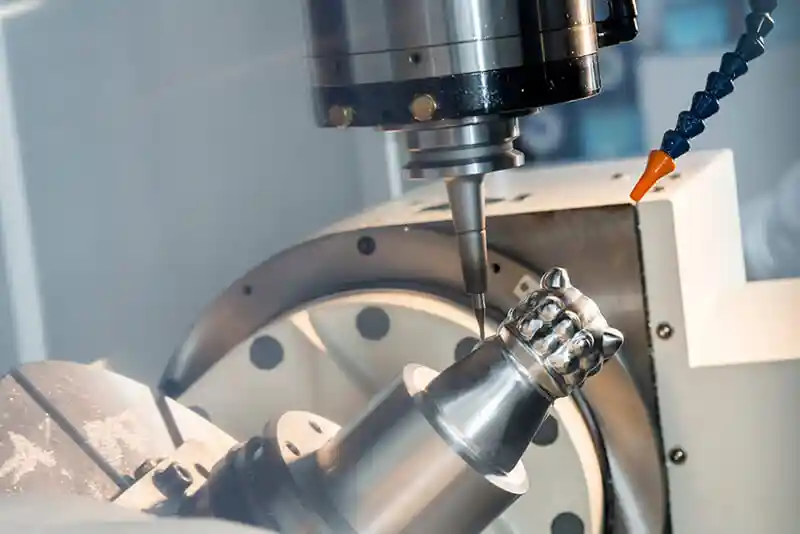

Milling: Removing material to create complex shapes and features.

Turning: Rotating a workpiece while a stationary cutting tool removes material to form cylindrical parts.

CNC machines can handle a wide range of materials such as metals, plastics, composites, and wood. They are commonly used in automotive, aerospace, electronics, medical, and consumer goods manufacturing.

V.The Importance of CNC Machining

CNC machining has become essential in modern manufacturing due to several key advantages:

High Precision: CNC machines achieve micron-level precision, making them ideal for manufacturing intricate parts.

Consistency: CNC machines can produce parts with consistent quality, minimizing errors and defects.

Increased Speed: These machines can operate 24/7, improving productivity and reducing lead times.

Complex Parts: CNC machining can create complex geometries and parts with detailed features that would be impossible with manual machining.

VI.6 Common Types of CNC Machines

• CNC Milling Machines: Used for cutting and drilling.

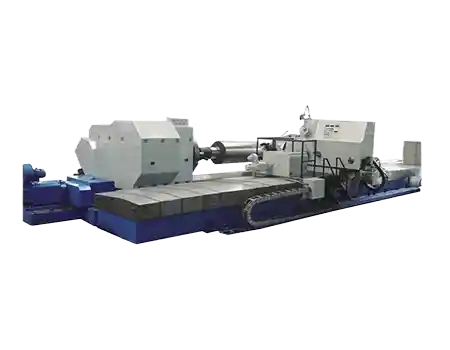

• CNC Lathes: Used for turning operations.

• CNC Routers: Used for cutting wood, plastics, and composite materials.

• CNC Plasma Cutters: Used for cutting metal with a plasma torch.

• CNC Electric Discharge Machines (EDM): Used for shaping hard metals and creating complex cavities.

• CNC Laser Cutters: Used for precise cutting using a focused laser beam.

VII.How Does a CNC Machine Tool Work?

CNC machine tools follow a set of programmed instructions to perform specific operations. Here’s the process:

• Design Creation: Use CAD software to design the part.

• CNC Program Generation: Convert the CAD design to G-code using CAM software.

• Program Loading: Load the program into the machine’s controller.

• Machine Setup: Install necessary tools, secure the workpiece, and configure machine settings.

• Execution: The machine follows the program’s instructions to cut, drill, or mill the part.

• Monitoring: Throughout the process, feedback systems monitor performance and adjust for any variations, ensuring accuracy.

VIII.How Does CNC Milling Work?

CNC milling uses a rotary cutter that moves along multiple axes to shape the workpiece as specified in the CNC program. This method allows for the creation of complex shapes from a variety of materials, including metals, plastics, and composites.

IX.How Does CNC Turning Work?

CNC turning involves rotating the workpiece while a stationary cutting tool removes material. This process is used to create cylindrical parts such as shafts and rods.

X.Advantages and Disadvantages of CNC Machining

Advantages:

• High precision and accuracy

• Consistent quality

• Increased production speed

• Reduced human error

• Ability to create complex parts

Disadvantages:

• High initial cost

• Requires skilled operators and programmers

• Maintenance can be expensive

• Limited by machine and tool capabilities

XI.What Are the Most Common Cutting Tools for CNC Machining?

CNC machining uses various cutting tools, including:

-End mills

-Drills

-Turning tools

-Taps

-Reamers

-Boring bars

These tools are made from materials such as high-speed steel (HSS), carbide, and ceramics, capable of withstanding the demands of machining.

XII.What Materials Can Be CNC Machined?

CNC machines can process a wide range of materials:

-Metals: Aluminum, Steel, Titanium

-Plastics: Acrylic, Nylon, Polycarbonate

-Composites: Carbon fiber, Fiberglass

-Wood

-Foam

XIII.CNC Machining Parts with Geometric Complexity: What Are the Design Limitations?

Certain design limitations should be considered when creating parts for CNC machining:

Deep cavities and sharp internal corners can be difficult to machine.

Consider the accessibility of tools for parts with complex undercuts or sharp features.

XIV.What Are the Trends in the CNC Machining Industry?

Key trends influencing the CNC machining industry include:

• Increased Automation: The use of robots and automated systems is improving efficiency and precision.

• IoT Integration: Real-time monitoring, data collection, and predictive maintenance are becoming commonplace.

• Improved Software: Advances in CAD/CAM software streamline design and programming.

• Additive Manufacturing: A combination of CNC machining and 3D printing offers greater design flexibility.

• Sustainability: Eco-friendly practices and energy-efficient machines are becoming more prevalent.

Conclusion

CNC technology is indispensable in modern manufacturing, offering unrivaled precision and efficiency across various industries. As technology continues to evolve, the capabilities and applications of CNC machines will only expand, driving further innovation in manufacturing processes worldwide.

FAQs

How do I select the best CNC machine type?

Consider factors like the material, part complexity, and production volume. Different types of CNC machines are suited to different tasks, so choosing the right one depends on your specific needs.

Are CNC machines difficult to operate?

While CNC machines require skilled operators, they are relatively easy to use once programmed. With proper training, most operators can effectively manage CNC systems.

Is CNC machining fully automated?

While CNC machining is highly automated, operators still need to monitor and program machines. Additionally, some tasks may require manual adjustments or interventions.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763