The Difference Between Linear Guides and Hard Rails

Why do some machine tools achieve high-speed cutting like a breeze, while others remain as stable as a rock under heavy loads? The answer often lies in a component that's easily overlooked: the guide rails. They determine the machine's movement precision, load-bearing capacity, and operational efficiency. But the key point is: not all guide rails are created equal.

In essence, both linear guides and hard rails are tools—each with its own specialization. Linear guides are precision experts, excelling in high-speed, high-precision, and low-maintenance light to medium cutting. Hard rails are load-bearing champions, providing exceptional stability in heavy-duty and high-cutting-force scenarios.

In this article, we'll explore the core differences between these two types of guide rails to help you find the most suitable choice.

1. What Are Linear Guides and Hard Rails?

Before we dive into the comparison, let's establish some common understanding. Both linear guides and hard rails are used to guide the movement of machine tool axes (e.g., X, Y, Z axes), but their design principles and internal structures are completely different.

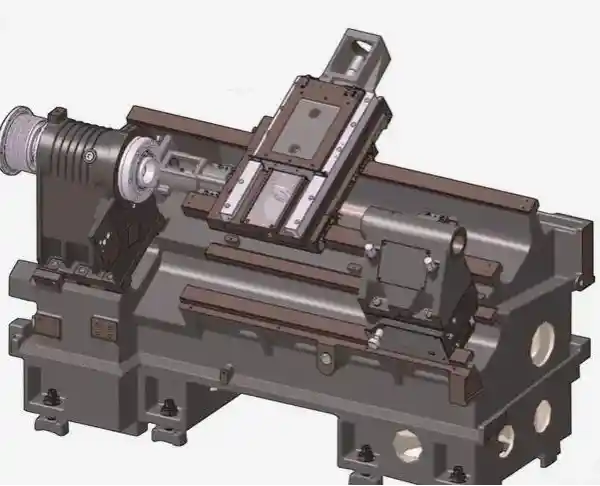

Linear Guides are designed for speed and precision. They operate based on rolling friction, where rolling elements significantly reduce resistance (similar to ball bearings). They are heat-treated to enhance hardness and then precision-ground to achieve micron-level tolerance, ensuring stable and reliable motion.

A modular structure includes:

Rigid ground guide rails

Sliding blocks that connect to moving components like the spindle slide

Rolling elements (balls or roller bearings) between the guide rails and blocks, fixed by retainers

Hard Rails, on the other hand, feature an integrated design, typically cast into the cast-iron bed or fitted with iron strips to form a long, flat surface. The moving parts rely on sliding friction and lubrication to reduce resistance. To enhance wear resistance, the guide rail surfaces are heat-treated to a Rockwell hardness of 50-60 HRC and then precision-ground or hand scraped to ensure flatness. Unlike linear guides, hard rails are a fixed part of the machine bed and have no modular design.

2. Performance Differences Between Linear Guides and Hard Rails

Now that we have the basic definitions, let's look at the actual performance differences. These aren't just technical parameters—they directly impact what your machine tool can and cannot do.

Precision: Linear guides can achieve an initial precision of ±0.001mm/1000mm. Due to their low friction and low wear properties, they maintain high precision over the long term, making them ideal for ultra-precise machining. Hard rails, with an initial precision of ±0.005mm/1000mm, depend on scraping quality and may experience wear from sliding friction, requiring regular maintenance to maintain accuracy.

Speed: Linear guides have a low coefficient of friction (0.001-0.005), enabling speeds of 60m/min or higher, suitable for mass automated production. Hard rails have a higher coefficient of friction (0.1-0.3), and when exceeding speeds of 15m/min, they generate excess heat, causing lubrication failure and metal-on-metal contact. Hard rails are better suited for heavy load stability than high-speed performance.

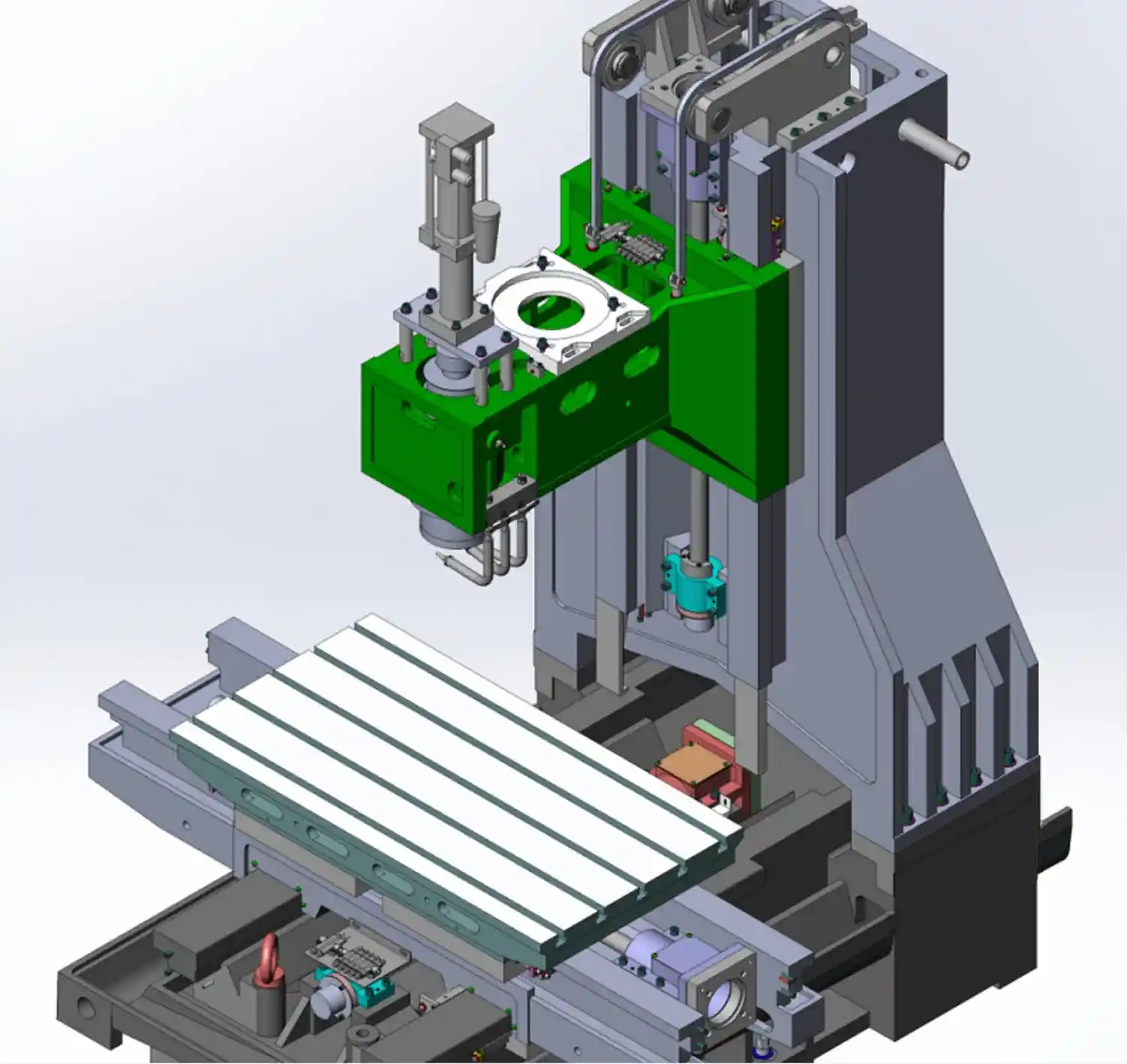

Load Capacity: Hard rails disperse the load over a large contact area, with a static load-bearing capacity exceeding 100kN, making them suitable for rough machining. Linear guides, with point contact from the rolling elements, have a static load capacity around 50kN, suited for dynamic loads. Heavy-duty models can improve load capacity by using larger roller bearings.

Rigidity: The large contact area of hard rails provides strong rigidity, effectively suppressing vibration during deep cutting. Linear guides, being less rigid, can balance precision and rigidity by adjusting preload and gap tolerance, making them suitable for medium cutting demands.

3. How to Choose Between Linear Guides and Hard Rails?

There is no "one-size-fits-all" solution—it's all about selecting the best fit for your needs.

Core Requirement | Choose Linear Guides if... | Choose Hard Rails if... |

Machining Materials | Aluminum, plastics, composite materials (light to medium cutting) | Steel, cast iron, titanium alloys (heavy cutting/high cutting forces) |

Machining Type | High-speed milling, 3D contouring, precision engraving | Rough machining, boring, heavy-duty milling (stability prioritized) |

Precision Requirements | ±0.001mm tolerance with long-term stability | ±0.01mm tolerance, prioritizing heavy load stability |

Production Volume | Mass production (automation, high throughput) | Small-batch custom parts (single or low-batch production) |

Machine Type | Vertical Machining Centers (VMCs, primarily for high-speed precision) | Horizontal Machining Centers (HMCs), Boring Mills (primarily for heavy-duty machining) |

Cost Considerations:

Purchase Cost: Hard rail machines are cheaper by 30-50% due to simpler manufacturing, making them ideal for budget-limited scenarios. Linear guides, due to the higher cost of precision components and brand premiums (e.g.,THK, HIWIN), have a higher price but offer significant advantages in speed and precision.

Maintenance Costs: Hard rails experience faster wear due to sliding friction, requiring frequent lubrication and periodic scraping (each service can cost thousands). Linear guides, with sealed designs that reduce contamination, experience low wear on the rolling elements. The sliding blocks are replaceable, and the lifespan can be predicted using the L10 formula.

4. Frequently Asked Questions

Here are some common questions we often receive:

Q: Are linear guides always more precise than hard rails?

A: Not necessarily. Well-maintained hard rails can achieve ±0.005mm precision, meeting most machining needs. However, linear guides maintain higher precision over time, especially under high-speed or dynamic loads, where sliding friction accelerates wear on hard rails.

Q: Can hard rail machines be used for high-speed machining in emergencies?

A: It is not recommended. Exceeding 15m/min on hard rails generates excessive heat, causing lubrication failure and direct metal contact, leading to surface quality degradation, accelerated wear, and expensive repairs. High-speed machining should be reserved for linear guide machines.

Q: How can I tell if my machine uses linear guides or hard rails?

A: It’s easy to spot! Linear guides have distinct sliding blocks (square or rectangular components) fixed to the rails, with end caps for circulating the rolling elements. Hard rails are smooth cast-iron strips on the machine bed with visible lubrication grooves.

Q: Can a machine use both types of guides?

A: Rare, but possible! Some custom machines use a combination: for example, hard rails on the X-axis for load-bearing and linear guides on the Z-axis for high-speed precision. This configuration solves specific scenario requirements but increases complexity and cost.

Conclusion

When making a decision, ask yourself: What materials do I most often machine? Do I prioritize speed and precision, or heavy-load stability? If you’re still unsure, feel free to contact Minnuo. We can provide scenario-based simulations (like load finite element analysis) to test the performance of different guide rails under your machining materials and cutting parameters to help you select the right guide rail.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763