What Role Do Servo Motors and Stepper Motors Play in Machine Tools?

Hello, as an engineer with years of experience at Minnuo, a one-stop solution provider for machine tool needs, I deeply understand that the precision and efficiency of machine tools are critical in every production process.

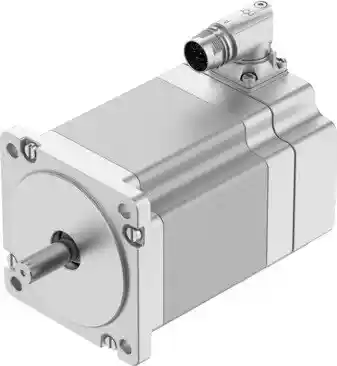

Servo motors (Servo Motors) and stepper motors (Stepper Motors) are key components that impact everything. When selecting a motor, it's not just about precision; factors such as load, speed, and cost also play important roles.

Let’s take a detailed look at how to make the most suitable motor choice based on the specific requirements of the machine tool.

I. Servo Motors and Stepper Motors: Working Principle and Application Comparison

Let’s first quickly understand the basic characteristics of these two types of motors to make the right choice.

• Servo Motors: Servo motors are driven by a closed-loop control system that adjusts position, speed, and torque based on real-time feedback, making them suitable for high-load and high-precision applications.

• Stepper Motors: Stepper motors operate through open-loop control, rotating by fixed steps. They do not have a feedback system and are suitable for low-load tasks with moderate precision requirements.

Feature | Servo Motor (Servo Motor) | Stepper Motor (Stepper Motor) |

Control Method | Closed-loop control, real-time feedback adjustment | Open-loop control, controlled by fixed steps |

Precision | High precision, suitable for complex motion control | Moderate precision, suitable for simple positioning tasks |

Application | High-load, high-precision machine tools and automation systems | Low-load, low-speed automation equipment and small machine tools |

Cost | Higher | Lower |

Dynamic Response | Fast, adapts to load changes | Slower, suitable for stable low-speed applications |

II. How Stepper Motors and Servo Motors Affect Machine Tool Precision?

In my experience, controlling precision is essential for every machine tool. The choice between servo and stepper motors directly affects the machine's positioning accuracy and processing quality.

Precision of Servo Motors

• Servo motors use closed-loop control, adjusting the motor's speed, position, and torque in real-time.

• Even under high speed or load variations, servo motors can maintain precise control.

• They are ideal for high-precision tasks, such as high-speed CNC milling machines and lathes, ensuring that each cut is precise.

Precision of Stepper Motors

• Stepper motors rotate in fixed steps and are suitable for low-load and low-speed applications.

• In such scenarios, stepper motors can provide sufficient precision to meet requirements.

• However, stepper motors may not achieve the same level of precision as servo motors when load variations are high or when higher precision is required.

Impact of Control Precision on Processing

• If your machine tool needs high-precision processing, the closed-loop feedback system in a servo motor ensures precise control during the process.

• Conversely, if your application involves lighter loads and has less stringent precision requirements, a stepper motor can still provide adequate precision while reducing equipment costs.

III. How to Choose the Right Motor Based on Machine Tool Requirements?

When selecting a machine tool, there are many factors to consider in addition to precision. Based on my years of experience, the following aspects are key factors in deciding which motor to choose:

1. Precision Requirements

• High Precision: If your machine tool requires high-precision cutting, such as in aerospace, medical, or high-end mold manufacturing, a servo motor is undoubtedly the best choice. It can maintain extremely high precision even with fluctuating loads.

• Medium/Low Precision: Stepper motors are very suitable for applications with lighter loads and moderate precision requirements, such as small automation equipment or simple engraving machines. In this case, stepper motors can not only meet the demand but also reduce costs.

2. Load Requirements

• High Load: Servo motors can adjust power based on load variations, ensuring high efficiency and stability under heavy load conditions. For large CNC machine tools or heavy automation equipment, servo motors can provide continuous power support.

• Low Load: Stepper motors are ideal for light-load applications, such as small machine tools and 3D printers. They provide adequate precision and are very cost-effective.

3. Speed Requirements

• High-Speed Processing: If your work requires high-speed cutting or rapid movement, the fast dynamic response of servo motors makes them the best choice for high-speed CNC equipment. They can accelerate quickly and maintain precise position control, making them ideal for high-speed cutting and processing.

• Low-Speed Operation: Stepper motors are more suitable for low-speed precision tasks, such as low-speed automation assembly lines. Stepper motors can maintain stable operation at lower speeds without affecting precision.

4. Cost Considerations

• Adequate Budget: Servo motors are relatively expensive, but their high precision, high load capacity, and fast dynamic response make them well worth the investment for machines that require high performance. If your equipment demands high precision and efficiency, a servo motor is the right choice.

• Limited Budget: Stepper motors are a very cost-effective choice, especially for low-load, moderate precision applications. For small equipment or tasks that don't require high performance, stepper motors provide an excellent cost-to-performance ratio.

5. Maintenance and Service Life

• Low Maintenance Requirements: Stepper motors have a relatively simple structure and require little adjustment or maintenance, making them suitable for devices where maintenance costs need to be controlled.

• High Performance and Maintenance: Servo motors, while requiring more maintenance and calibration, are indispensable in high-precision processing due to their high performance and long-term stable operation.

Conclusion:

Choosing the right motor is not only a technical issue but also crucial for optimizing the entire production process. If you are purchasing a high-precision, high-load machine tool, a servo motor is undoubtedly the better choice. On the other hand, if you need a small, low-load, cost-effective machine, a stepper motor is more suitable.

If you have any doubts about how to choose or are currently selecting the right machine, feel free to contact us at Minnuo. We are a one-stop solution provider for machine tools, not only capable of answering your questions but also helping you select the most suitable machine.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763