Breaking Through Under Tax Pressure: How China’s Manufacturing is Regaining Global Influence Through Technology

As former U.S. President Donald Trump once again pushes for increased tariffs on Chinese goods, concerns rise over whether China’s manufacturing sector will fall into a passive position. Amid intensifying international trade tensions and mounting tariff pressure, can China’s high-end machine tools break through the siege and gain recognition in the global market?

This time, however, is different. Unlike in the past, China’s manufacturing sector is not passively enduring the narrative storm but is instead experiencing a surge in technological validation. For the machine tool industry—at the very heart of manufacturing—this “tariff storm” presents not only pressure but also a rare opportunity to test its technological maturity and market resilience.

This apparent crisis might well be the turning point that heralds a new era—where China’s manufacturing regains its voice on the global stage through technology.

I. Core Technology Breakthroughs: From "Bottlenecks" to "Autonomous Control"

1. Significant Progress in Core Component Localization

Chinese machine tool manufacturers have achieved key breakthroughs through collaborative innovation among industry, academia, and research institutes. For example, Jiangsu Okada Intelligent developed a high-precision tool magazine through in-house design and cooperation with universities, reducing costs by over 30% while matching the lifespan and accuracy of leading international brands.

Shenyang Jianzhu University developed an intelligent ceramic electric spindle featuring axial cooling and circumferential jet technologies, achieving thermal expansion control within ±0.002mm. The product has passed national-level testing, filling a critical gap in China’s high-end spindle segment.

In CNC systems, Huazhong CNC launched the world’s first "Huazhong 10" intelligent CNC system. Integrating AI algorithms, it supports tool life prediction and energy consumption optimization. Comparable to Siemens, it is now in use in advanced machining centers at companies like Qinchuan Machine Tool and Shenyang Machine Tool. In 2024, domestic CNC systems’ market share in the mid-to-high-end segment increased by 8 percentage points year-on-year, with key technologies such as 5-axis RTCPand inclined surface machining reaching international standards.

Domestic replacements for ball screws and linear guides are accelerating. According to CITIC Construction Investment, Chinese-made ball screws used in humanoid robotics deliver 3–5 times higher load capacity and 2–3 times longer service life, with accuracy within ±0.002mm. These products have entered Tesla’s Optimus supply chain. In Tengzhou’s Intelligent Manufacturing Park, CNC machine tools now hold 35% of the domestic market share, with exports up 22% year-on-year. Locally produced ball screws are widely used in new energy auto parts machining.

2. Key Process Capabilities Now Align with Global Frontiers

China’s 5-axis CNC machines are widely adopted in high-demand sectors such as aerospace and medical equipment.

Gree Electric’s “High-Speed Dual 5-Axis Gantry Machining Center” won gold at the 2025 Geneva International Invention Exhibition. It achieves ±0.003mm machining accuracy and thermal drift under 0.001mm during 24-hour continuous operation, improving precision mold efficiency by 40%.

Kede CNC’s horizontal 5-axis mill-turn center, developed for aircraft engine blisks, adopts an innovative 6-axis 5-linkage structure, enhancing efficiency by 600% and breaking the monopoly of Western enterprises.

In the medical field, domestic machines are proving reliable. Everfine’s 5-axis machine processed orthopedic instrument molds with consistent ±0.003mm precision. Supporting 24/7 production, it outperforms some Japanese brands in thermal stability, while users report a 30% increase in system responsiveness and repair response times of under 4 hours.

3. Digital Capabilities Powering Smart Manufacturing Upgrades

The new generation of Chinese machine tools leverages industrial internet technologies for full-process optimization. Qizhong CNC’s precision vertical turn-mill-grind center adopts a direct-drive table to eliminate multi-stage transmission errors. It achieves ±0.005mm positioning accuracy and connects with MES systems for coordinated production optimization.

Haier’s factory, powered by smart machine tools and AI-based vision inspection, increased inspection precision from 0.1mm to 0.01mm, boosting production efficiency by 40%. Remote equipment monitoring and energy diagnostics are also supported.

II. Supply Chain Restructuring: From "Import Reliance" to "Localized Loop"

1. Coordinated Development of Regional Industrial Clusters

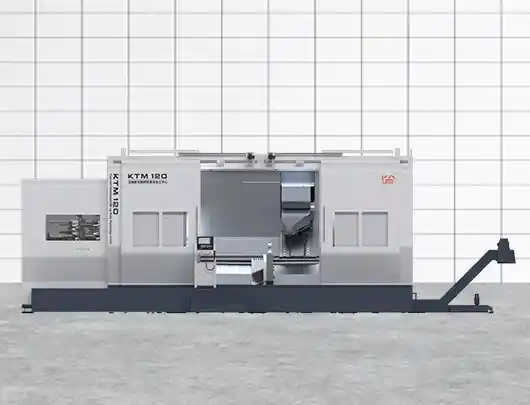

The Shenyang-Dalian industrial mother machine cluster, backed by Shenyang Machine Tool and Dalian Guangyang, has built a full-chain system from core component R&D to complete machine manufacturing. By 2024, the cluster leads nationally in 5-axis high-speed machining and intelligent CNC systems. High-end CNC exports account for 40% of the national total, covering critical sectors like aerospace and shipbuilding.

Tengzhou, dubbed “China’s Capital of Small-to-Medium Machine Tools,” is home to over 300 supporting enterprises in its smart manufacturing park. It offers localized supply from ball screws to CNC systems, cutting supply chain response times by 50% compared to imports.

2. Accelerated Domestic Substitution of Core Components

Qizhong CNC, a subsidiary of Huizhou Intelligent, developed high-precision hydrostatic guideway crossbeams. Its multi-channel independent oil supply system achieves micron-level control, reducing tool holder friction to just 0.001N. It’s used in wind power equipment processing, lowering costs by 40% compared to imports.

Kede CNC’s spindles and servo motors now serve energy and automotive sectors. In 2024 alone, new motor orders exceeded 10 million RMB, driving collaborative growth throughout the value chain.

III. Market Strategy Shift: From "Price Wars" to "Value Creation"

1. Technical Suitability Assessment Systems

Procurement decisions must focus on how well equipment meets industry-specific needs. For example, the new energy vehicle (NEV) sector demands versatile 5-axis capabilities. Everfine’s K7 5-axis model, designed for NEVs, features a mobile-column structure and rear chip discharge system, boosting efficiency by 50% in aluminum casting machining.

In aerospace, compound machining capabilities are essential. Kede CNC’s 5-axis horizontal mill-turn center integrates turning, milling, and grinding, enabling single-setup processing of complex parts like landing gear. This reduces equipment changeover time by 80%.

2. Supply Chain Stability Management

Local sourcing mitigates trade policy risks. Qizhong CNC’s hydrostatic guideway technology, now locally produced, cut spare part lead times from six months (for imports) to two weeks, with 24-hour maintenance response. Gree Smart Equipment and Guangdong Hongtu formed deep collaborations for NEV parts machining, achieving full-process integration and reducing equipment failure by 60%.

3. Unlocking the Potential of Digital Transformation

Smart factory upgrades must emphasize equipment openness and scalability. The “Huazhong 10” system offers open interfaces for easy industrial internet integration, enabling real-time monitoring and deep production analytics.

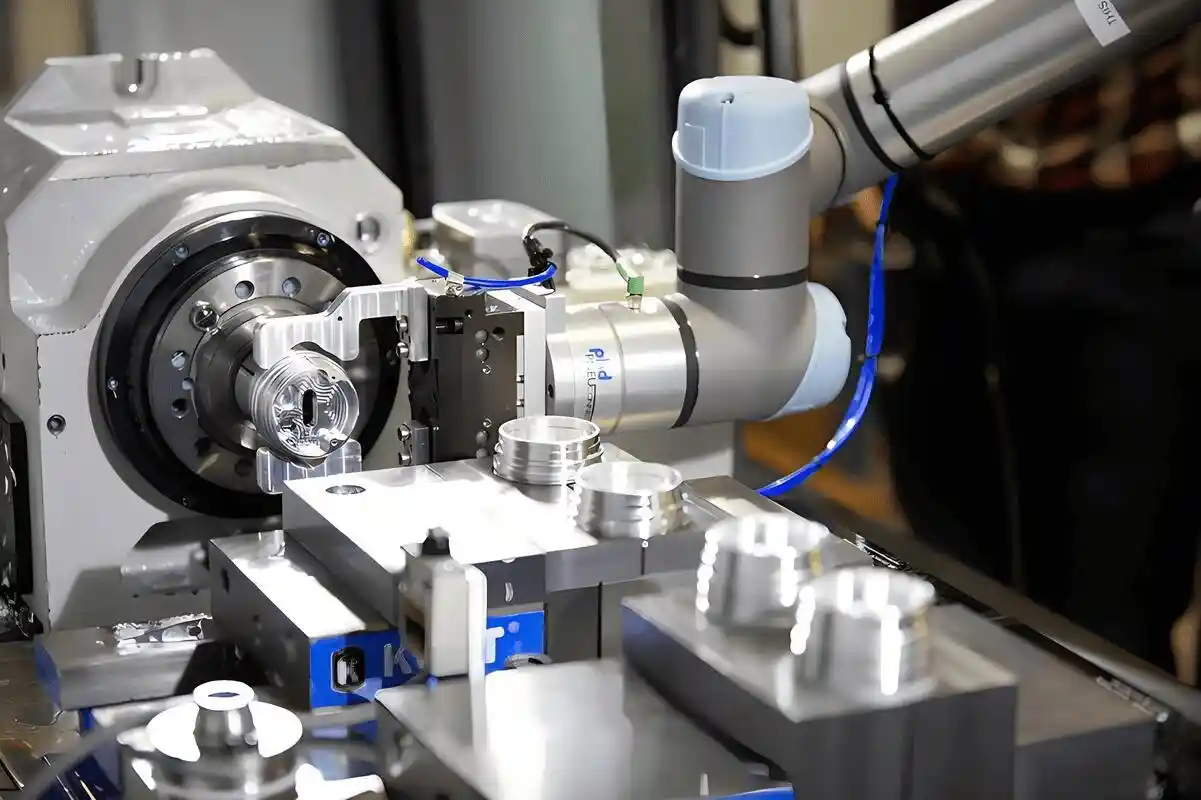

Kede CNC’s flexible automation lines, incorporating multiple 5-axis machines and intelligent logistics, dynamically adjust based on orders. This reduces changeover time by 70%, supporting the transition to “dark factories.”

IV. Systematic Capability Evolution: From "Single-Point Breakthroughs" to "Ecosystem Building"

The brands mentioned above highlight that China’s machine tool breakthrough is fundamentally about evolving full manufacturing systems.

Gree Electric, which entered high-end equipment from home appliances, has spent over a decade building an ecosystem from R&D to services. Its success with high-speed dual 5-axis gantry machines shows that China now has the capability to compete head-to-head with German and Japanese brands.

Kede CNC’s “Machine + Components + Services” business model yielded a 27.37% YoY profit increase in 2024, with average sales prices for 5-axis machines up by 27.49%, proving the market’s willingness to pay for technology. This evolution is not just technical but reflects broader synergy and standards advancement across the industry.

The Shenyang-Dalian cluster, together with universities and research institutes, co-developed standards like the “Precision Testing Specification for 5-Axis CNC Machines,” helping boost international acceptance of domestic equipment. In 2024, Chinese machine tools’ global high-end market share rose by 3 points, with 5-axis exports up 45%, becoming a new global symbol of "Made in China" technology.

V. Minnuo: Scenario-Driven Innovation as a Breakthrough Strategy

Minnuo is a representative of industrial transformation through scenario-based innovation. It focuses on high-end manufacturing use cases to build technical superiority:

5-Axis Machining Systems: Utilizing torque motor direct-drive and thermal compensation algorithms, Minnuo’s systems eliminate transmission gaps and correct thermal errors in real-time, achieving ±0.002mm positioning—ideal for complex aerospace titanium components.

Modular Flexible Units: With efficient quick-change structures and smart vision positioning, modules can be swapped in under 5 minutes. Supports multi-material machining (aluminum/carbon fiber), ideal for NEV small-batch, multi-variety flexible production.

Digital Twin Technology: Full-scale virtual modeling pre-optimizes stress distribution. Edge computing collects 30+ real-time parameters like vibration/temperature. Machine learning predicts tool life and diagnoses faults, extending component life by 25% and cutting machining deviations by 60%.

Ultra-Precision Processes: For semiconductors and thin-walled energy components, Minnuo uses hydrostatic guides and deformation compensation to control aluminum housing deformation within 0.05mm, maintaining table straightness error ≤1μm/m—matching the best international standards.

With a tightly coupled “Technology–Scenario–Application” development strategy, and a supply chain built on 85% localized core components, Minnuo demonstrates robust resilience and technical competitiveness amid global trade volatility. It exemplifies China’s shift from exporting equipment to exporting value.

Conclusion

China’s machine tool industry is undergoing a transformation—from follower to leader—through continuous technical upgrades and systematic capability development.

At this turning point of global industrial restructuring, “Made in China” is no longer just about cost advantage. It is becoming a comprehensive solution provider driven by innovation, collaboration, and ecosystem development.

If you have any questions about the technologies, application scenarios, or models mentioned in this article, feel free to contact Minnuo. We’re here to provide customized intelligent manufacturing solutions tailored to your needs, and to join hands in ushering in a new era of advanced equipment manufacturing.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763