CNC Turning and Milling Centers vs Standard CNC Lathes: What Makes Turn-Mill More Capable?

The manufacturing industry is gradually shifting towards "high complexity + high efficiency" processing. Traditional CNC lathes are gradually struggling to handle tasks that require multiple processes in a single setup. At this point, the CNC turning and milling center, with its "multi-in-one" processing advantages, has become a new favorite in modern machining centers. But is it truly stronger? Is it worth the investment to upgrade?

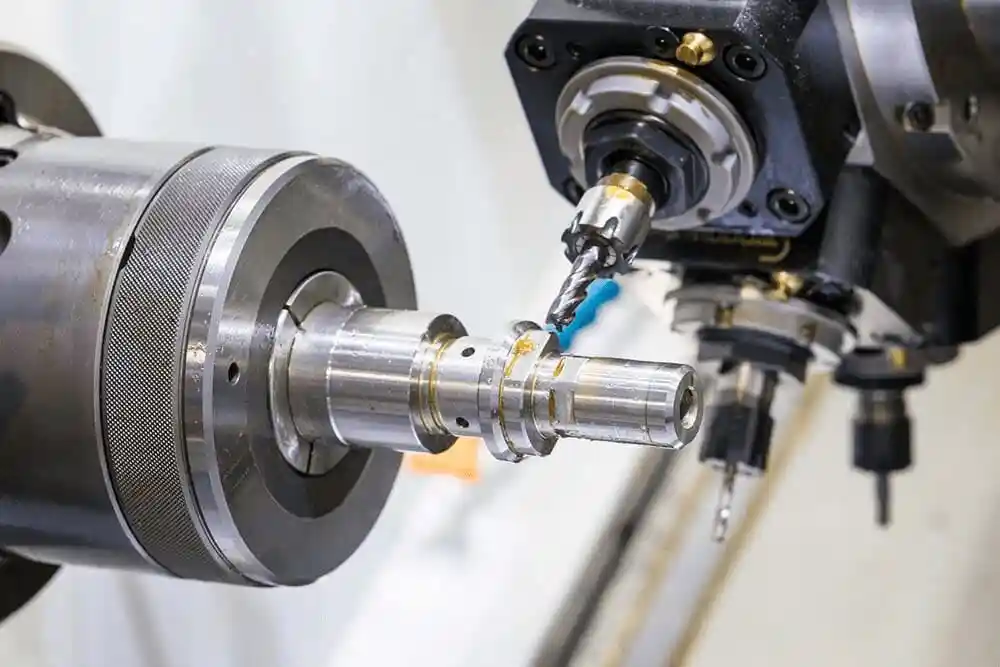

The CNC turning and milling center integrates various processes such as turning, milling, drilling, etc., allowing complex tasks to be completed with a single setup. Compared to standard CNC lathes, it features multi-axis structures, including Y-axis, multi-surface machining, and sub-spindles.

Can the arrival of turning and milling centers truly solve the limitations of traditional CNC lathes? Let’s take a closer look today.

1. Standard Lathe vs. Turn-Mill: What's the Difference?

Let’s compare the two machines with a clear table:

Comparison Dimension | Standard CNC Lathe | turning and milling center |

Processing Capability | Turning Only | Turning, Milling, Drilling, Tapping, and More |

Processing Efficiency | Multi-machine coordination, frequent tool changes | All processes in one setup, significantly improving efficiency |

Accuracy Consistency | Multiple setups lead to accumulated errors | One setup ensures overall consistency |

Ability to Handle Complex Structures | Weak, mainly suitable for rotational bodies | Strong, capable of machining complex features like non-circular holes, grooves, and inclined surfaces |

Programming and Operation | Simple programming, requires frequent manual intervention | Slightly more complex programming, but higher automation |

2. What is a Turning and Milling Center? How Does It Achieve These Advantages?

Turn-Mill is a type of compound CNC machine that integrates turning, milling, drilling, and other functions. Its core advantage is the ability to “complete all processing operations in one setup.”

Common configurations include:

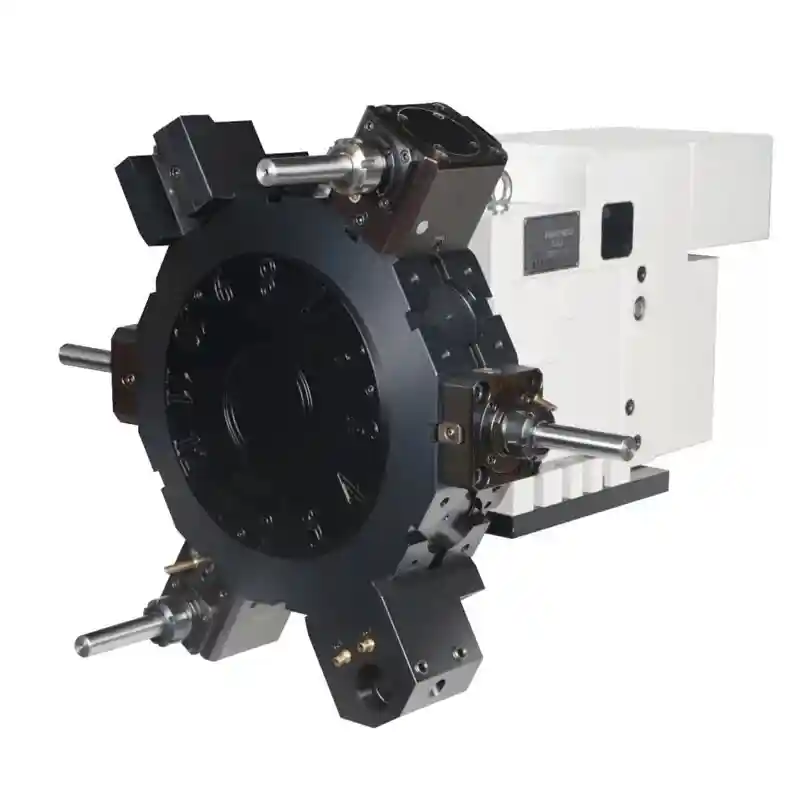

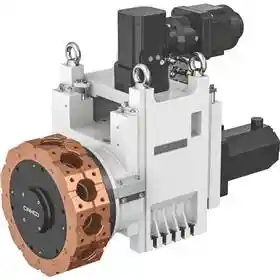

Power Tool Turret: Allows the tool not only to move but also to rotate for milling operations.

Sub-Spindle: Supports processing both sides of a workpiece.

Y-Axis: Allows eccentric and side machining (details below).

B-Axis (on some high-end models): Supports five-axis linkage for greater machining freedom.

3. What is the Meaning of the Y-Axis in a Turning and Milling Center?

The Y-axis is an important structure that standard lathes lack. It enables the machine to move not only "front to back" and "left to right," but also "up and down."

With the Y-axis, you can achieve:

Eccentric hole machining: No need for manual offsets or fixture adjustments.

Eccentric hole machining: No need for manual offsets or fixture adjustments.

Groove, cavity, and step structure machining: Tools can move horizontally.

Inclined surface or side milling: No longer a process blind spot.

Machining Task | Without Y-Axis | With Y-Axis |

Eccentric hole drilling | Fixture change or error compensation | Directly set eccentric position and complete the machining automatically |

Step grooves | Multiple setups or additional processes | Easily control lateral feed for cutting with Y-axis |

Asymmetric structure machining | Requires manual positioning and multiple tool adjustments | Machine automatically compensates with multi-axis machining |

The Y-axis upgrades your machining capability from 2D to 3D. For more complex parts, tasks without the Y-axis are either impossible or too costly and inaccurate to make sense.

4. What Tasks Can Turning and Milling Center Handle Beyond Basic Turning and Milling?

Its power goes beyond “turning and milling.” It can also handle:

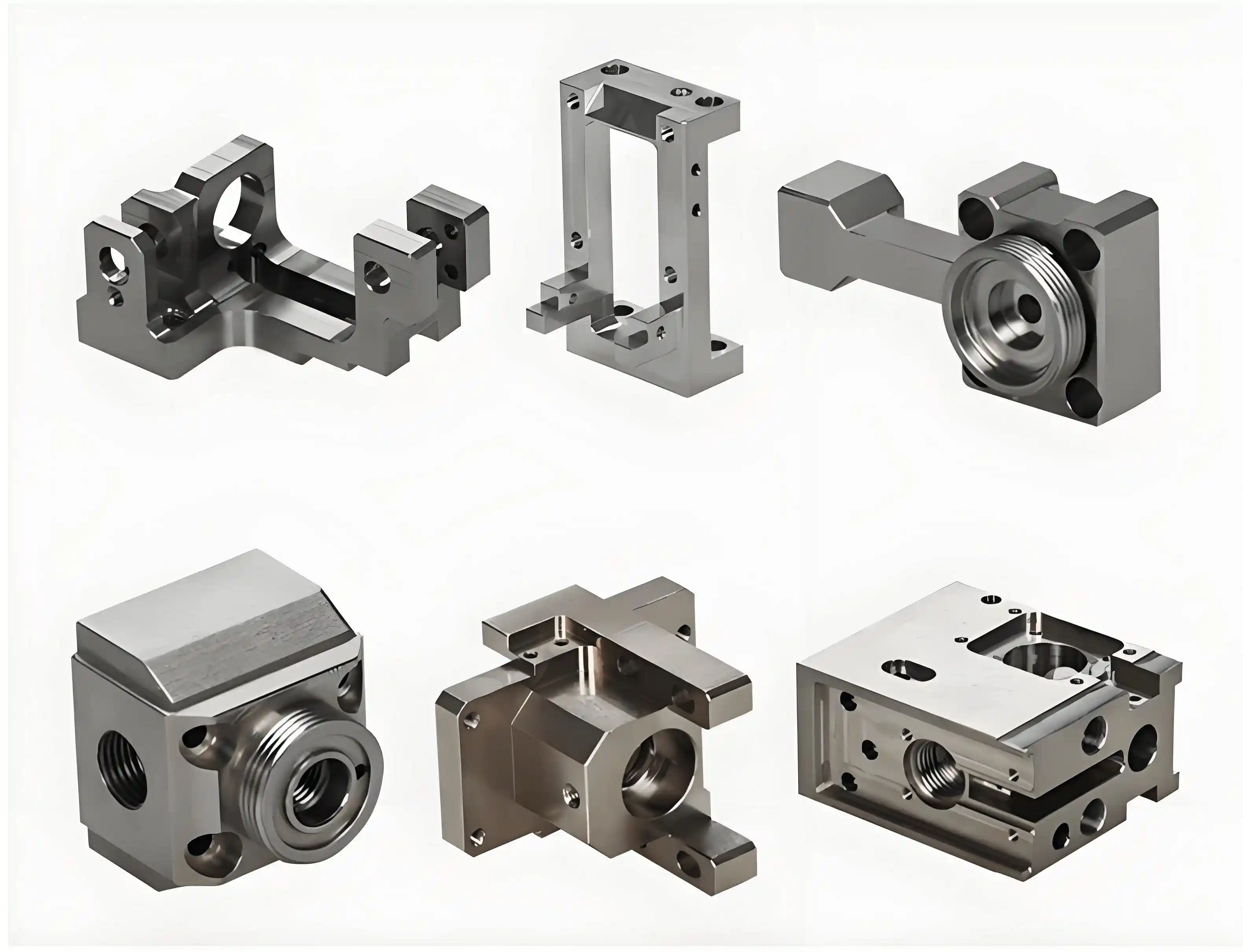

Inclined holes, grooves, step compounds.

Uneven-depth cavities, eccentric structure combinations.

Spiral channels, cooling grooves, multi-surface hole parts.

Front and back interlocking structures (via sub-spindle).

Irregular geometric contours and internal composite structures simultaneously machined.

5. Which Industries are Best Suited for Turning and Milling Center?

High-adaptability industry scenarios:

Medical devices: Bone screws, joint brackets, precision fittings, one-piece complex structures.

Aerospace parts: Multi-inclined surfaces, multi-axis holes, multi-surface structural parts.

Precision molds: Small batch, high variability, high structural precision requirements.

Electronic connectors: High-complexity small parts, where the compound machine doubles the efficiency.

6. Is Turning and Milling Center Worth Buying? You’ll Understand After These Four Steps

Many people’s biggest concern when buying is cost. Is it really worth purchasing?

We won’t just speak from feelings, but here’s the “Scientific Selection Method” for you to figure out if Turn-Mill is suitable for you:

Scientific Selection Method:

Clarify the processing needs of the parts:

Are the geometries complex? Do they involve multiple directions and processes?

Are the precision requirements strict (e.g., ±0.01mm)?

Identify existing bottlenecks in the shop: Are there frequent tool changes, positioning errors? Do workers switch between different machines?

Calculate ROI and optimize labor costs:

Can the single-part machining cost be covered by Turn-Mill's efficiency?

Can it reduce fixtures, transportation, and labor costs?

Choose a model with Y-axis and multi-surface processing capabilities:

Does it have a Y-axis? Can it process both sides automatically?

Does the manufacturer provide programming training, after-sales support, and process consulting?

If you identify pain points in the first three steps, step 4 is when you should seriously consider a solution provider like Minnuo.

7. Conclusion:

Upgrading your workshop is not about “stacking machine tools,” but about “smart collaboration” and “efficiency integration.” If you're still deciding which machine to choose, feel free to contact Minnuo. As a solution-oriented machine tool manufacturer, Minnuo provides one-stop services to help you select the best machine model and configuration, efficiently handling complex machining challenges.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763