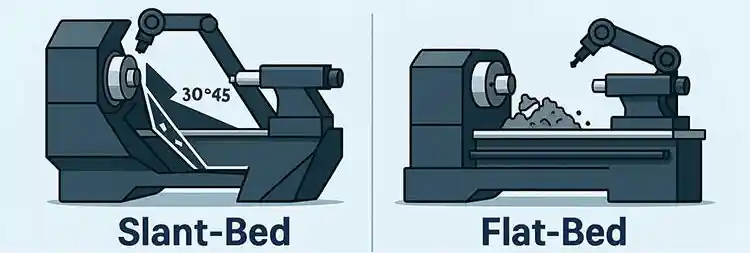

Difference Between Slant Bed and Flat Bed CNC Lathes

In modern manufacturing, CNC lathes are widely used for various machining tasks, whether for mass production or custom parts. The bed design, being the foundation of a CNC lathe, directly impacts machining precision, production efficiency, and machine stability. Therefore, choosing the right type of bed design is crucial.

Flat bed lathes have a simple structure, are suitable for conventional machining tasks, easy to maintain, and cost-effective. On the other hand, slant bed lathes, with their inclined design, enhance chip removal efficiency, improve rigidity and stability, making them more suitable for high-speed and high-precision machining, especially for high-load and complex tasks.

Today, we’ll dive into the differences between slant bed and flat bed CNC lathe designs. Whether you're purchasing a lathe for the first time or looking to optimize your existing equipment, it's worth understanding the distinct advantages behind these two designs.

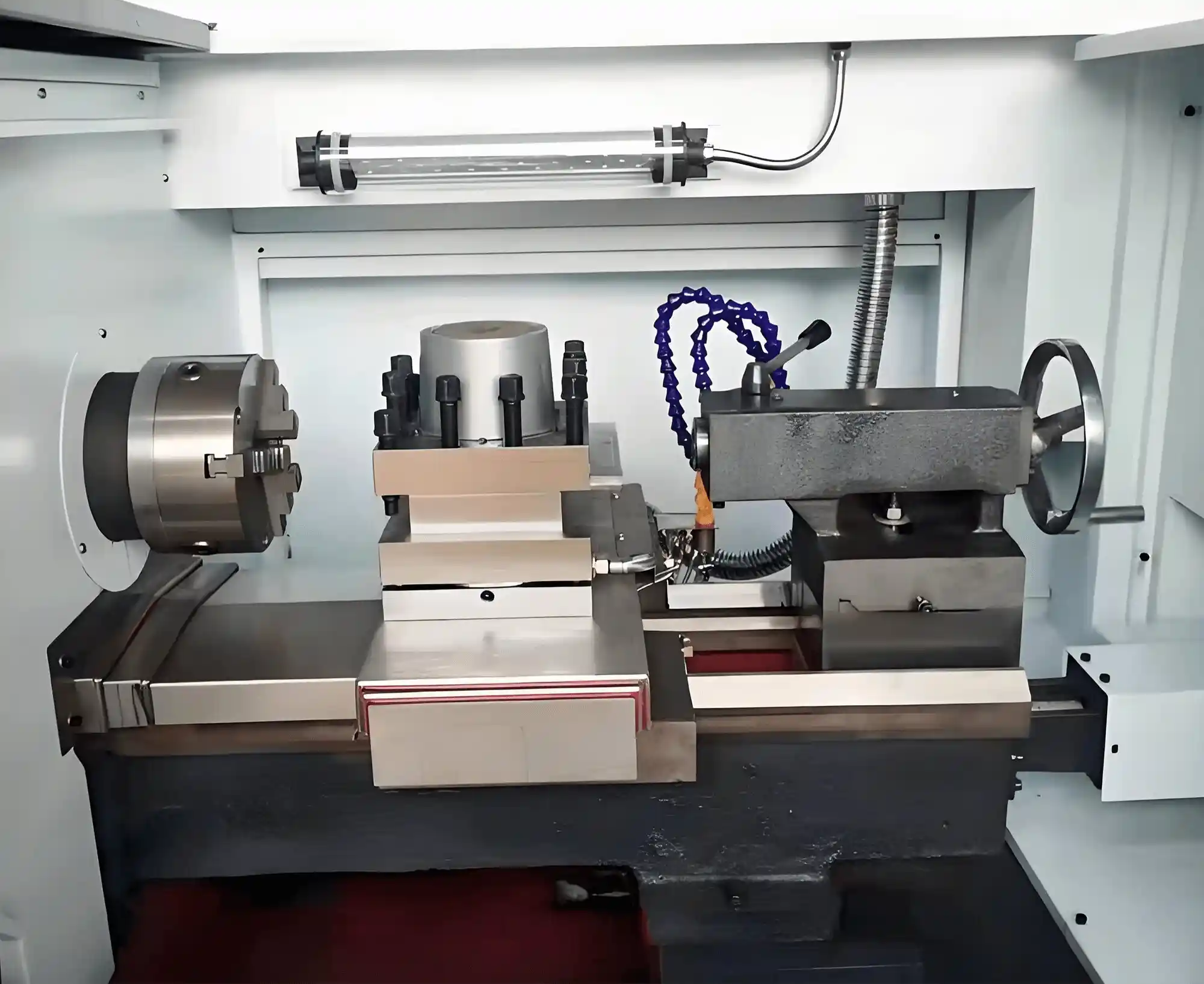

I. What is a Slant Bed CNC Lathe?

A slant bed CNC lathe features an inclined bed design, usually at an angle of 45° or 30°. This design enhances the lathe's structural stability, ensuring better precision, especially during high-load or high-speed cutting operations.

Key features of slant bed lathes:

Inclined Design: The slant angle helps optimize chip removal, preventing chip accumulation that could affect machining quality.

Enhanced Rigidity: The slant bed design increases the machine's rigidity, ensuring high machining precision.

Improved Efficiency: Slant bed lathes are typically more compact and designed for high-efficiency, high-precision machining tasks.

Applications:

High-precision machining

Complex part production

Large-volume production requirements

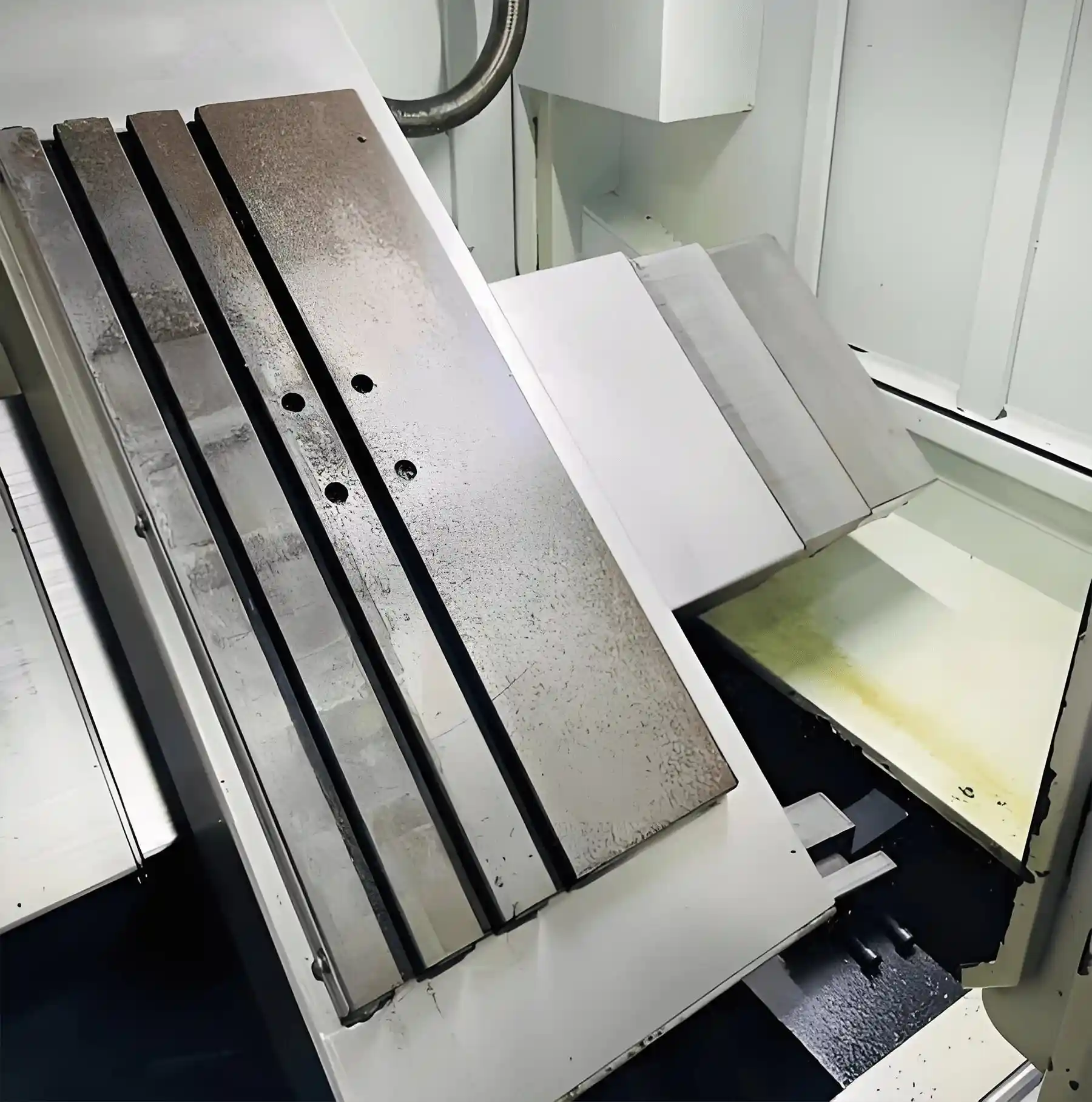

II. What is a Flat Bed CNC Lathe?

Unlike slant bed lathes, flat bed lathes feature a horizontal bed design. They are simple in structure, stable, and easy to maintain. The traditional flat bed design is generally used for more straightforward machining tasks.

Key features of flat bed lathes:

Traditional Design: Simple and direct, the structure is easy to understand, and operation is straightforward.

Wide Applicability: Ideal for most conventional machining tasks, especially when high precision is not a strict requirement.

Easy Maintenance: The simple structure leads to fewer maintenance needs.

Applications:

Machining tasks with standard precision requirements

Small to medium production volumes

Small workshops or startups

III. Key Differences Between Slant Bed and Flat Bed CNC Lathes

Let’s compare the slant bed and flat bed lathes in practical terms. By comparing their features, you’ll be able to understand their strengths more clearly and make a decision based on your specific production needs.

Comparison Item | Slant Bed CNC Lathe | Flat Bed CNC Lathe |

Bed Angle | 45° or 30° slanted design for optimized chip removal | Horizontal design, chip removal can be harder |

Rigidity & Stability | Stronger rigidity, ideal for high-speed and heavy-load machining | Good stability, suitable for lighter loads or conventional machining tasks |

Space & Ergonomics | Compact design, easy operation | Simple design, easy to maintain |

Applicability | High-precision machining, efficient production | General machining tasks, small batch production |

Machining Efficiency | Higher efficiency, especially for complex part machining | Lower efficiency, suitable for basic parts |

IV. Cost Comparison Between Slant Bed and Flat Bed CNC Lathes

Initial Investment:

Slant bed lathes come with a higher initial investment but provide better returns in terms of efficiency and precision over the long term.Flat bed lathes, while cheaper initially, may face more maintenance or production bottlenecks due to their limited efficiency and precision.

Long-term Maintenance Costs:

Slant bed lathes are designed with more advanced features and better chip removal systems, reducing the frequency of maintenance.Flat bed lathes, due to their simpler structure, are easier to maintain but may require more frequent maintenance for high-load or complex parts.

Production Efficiency:

Slant bed lathes are perfect for mass production, providing higher efficiency and precision. Over time, they yield significant economic benefits for high-volume production.

Flat bed lathes are suited for single or small-batch production, offering lower costs but may struggle to compete with slant bed lathes in large-scale manufacturing.

V. Advantages of Flat Bed CNC Lathes

Ideal for General Machining Needs: The simple design of flat bed lathes makes them great for machining tasks that don’t require extreme precision.

Low Cost: For smaller shops or single-piece production, flat bed lathes are a cost-effective solution.

Ease of Maintenance: Their simple structure ensures that maintenance is straightforward, making them ideal for workshops with less stringent maintenance requirements.

VI. Advantages of Slant Bed CNC Lathes

Improved Chip Management: The slant bed design ensures smooth chip removal, preventing accumulation that could compromise machining accuracy. This is particularly beneficial in high-output and complex machining operations.

Increased Rigidity and Stability: The slant bed design enhances machine rigidity, ensuring stable machining even under high-speed and heavy-load conditions, thereby maintaining high accuracy.

Enhanced Work Efficiency: The compact design and efficient chip removal of slant bed lathes make them ideal for processing long parts or complex components, particularly for large-volume production.

Extra Tip: Why Do CNC Turning Centers Use Slant Bed Configuration?

If you’ve ever wondered why many CNC turning centers use the slant bed design, here’s a quick explanation:

Slant bed lathes not only improve chip removal efficiency but also significantly increase machine rigidity. The slanted angle ensures greater stability during high-speed and heavy-load cutting, leading to better overall machining precision. This design is irreplaceable in industries requiring extremely high precision, such as aerospace and precision manufacturing.

VII. Choosing Between a Slant Bed CNC Lathe and a Flat Bed CNC Lathe

When selecting the right CNC lathe, we recommend considering the following factors:

Type of Material: For tougher or more complex materials, slant bed lathes generally perform better. Flat bed lathes can handle standard materials well.

Production Volume: In mass production, slant bed lathes excel with their efficient chip management and high precision.

Budget: If budget is tight, a flat bed lathe is a cost-effective choice. However, over time, the efficiency advantages of a slant bed lathe may provide better returns.

VIII. Common Misunderstandings and FAQs

Misunderstanding 1: Slant bed lathes are always better for high-precision machining?

Answer: While slant bed lathes perform excellently in high-load and high-speed operations, not all precision machining requires a slant bed. For low-load and simpler tasks, a flat bed lathe can offer sufficient accuracy.

Misunderstanding 2: Flat bed lathes are unsuitable for heavy-load machining?

Answer: Flat bed lathes are designed for conventional machining tasks and can handle certain loads well, especially for simpler components. In specific situations, they may still manage moderate loads effectively.

IX. Conclusion:

Whether you’re handling high-speed, high-precision production tasks, or simpler conventional machining, choosing the right lathe can significantly improve your production efficiency and machining quality. We hope today’s guide helps you make an informed decision.

If you still have questions regarding the differences between slant bed and flat bed lathes or are unsure which one suits your needs, feel free to reach out to Minnuo. We provide expert technical support and personalized consultation services to help you select the best equipment, enhancing your production efficiency and quality.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763