Regular maintenance

9-Axis / 5-Axis Simultaneous Multitasking Turning-Milling Centers MTN Series

-

Maximum swing diameter: φ700

-

Maximum turning diameter: φ700

-

Maximum processing length:1580/2500/3000mm

Full 6-face machining in one setup • Dual spindle & dual tool magazine configuration

The MTN Series is a third-generation multitasking horizontal turning and milling center, featuring up to 9 axes and 5-axis simultaneous machining for complete six-face processing in one setup. With an orthogonal Y-axis, dual spindles, and a hybrid tool system, it offers high flexibility for complex, high-precision parts in energy, automotive, and general machinery industries.

MTN Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Orthogonal Horizontal Y-Axis Layout: The machine adopts a space-optimized Y-axis structure that enables full-sided accessibility while ensuring rigidity and thermal symmetry during multi-surface machining.

- ● Integrated Multi-Function Machining: Supports turning, milling, boring, drilling, and tapping in one clamping. Full 6-face machining enabled by main spindle, sub-spindle, and B-axis milling head with 12000 rpm capability.

- ● Advanced Thermal & Cooling Control: Built-in thermal balance system and targeted coolant circulation prevent heat-induced deformation, enhancing long-cycle machining stability and precision.

- ● Dual Tool Magazine System: Standard 40-tool chain magazine (option for 80 tools) plus 6-slot auxiliary milling tool holder. This setup expands tool capacity for long and varied machining cycles without tool change delays.

- ● High Productivity Ergonomics: Features auto door, multi-position control panel, and programmable chip management for improved user comfort and productivity.

Recommended Configurations

- ● Spindle Configuration: High-speed electric spindle, dual-spindle system (including main spindle and sub-spindle)

- ● Tool System: Tool interfaces: HSK-T63, CAPTO C6、Tool magazine capacity: 40 tools, 80 tools, 120 tools、Auxiliary tool magazine capacity: 6 tools、Servo-driven turret、Tool compensation system

- ● Workholding System: Main spindle hydraulic chuck: 12-inch, 15-inch、Sub-spindle hydraulic chuck: 10-inch, 12-inch、Steady rests: K5.1 (SMW), K6 (SMW)、Servo-driven tailstock

- ● Feed and Drive System: Linear drive、Ball screws (XY/Z ball screws with oil cooling + oil-air lubrication)、Roller linear guideways、Servo motors

- ● Cooling and Chip Removal System: Internal coolant system (2 MPa and 7 MPa high-pressure options)、Magnetic scraper-type chip conveyor、One-touch self-cleaning system

- ● High-Precision System: XY/Z linear scales、X2/Z2 linear scales

- ● Control System: High-performance CNC systems (FANUC, Siemens, GSK, KND, SYNTEC, Mitsubishi, etc.)

Application Case

- ● Client: Precision Machinery Supplier – Southeast Asia

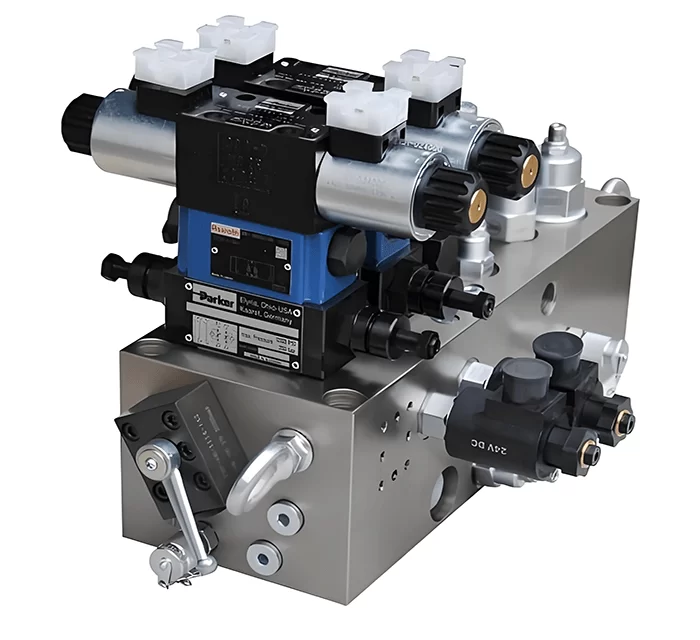

- ● Workpiece: Hydraulic control valve block (complex inner channels, multi-face machining)

- ● Setup: DTM-B70ST/1500 with B-axis head, 40+6 tool stations, main/sub spindle with synchronized control

- ● Results: • Process Integration: Reduced five-stage machining process into one setup • Accuracy Achieved: Surface finish Ra ≤ 0.8 µm, position tolerance ≤ ±0.015 mm • Efficiency Gain: 40% cycle time reduction and 50% labor savings

- ● Client Feedback: “The DTM multitasking center has helped us transition from conventional machining to high-precision, one-stop production. Its flexibility and accuracy have drastically improved our capacity and reduced lead times.”

Product Specifications

0

Catalog

Frequently Asked Questions

Turning and milling center can typically process various metals (such as aluminum alloys, steel, stainless steel, etc.), and some non-metallic materials. You can select a machine model that supports the specific materials you need.

For aluminum, it can reach Ra 0.8μm; for steel, Ra 1.6μm; for cast iron, Ra 3.2μm.

As a professional cnc milling and turning manufacturer, Minnuo offers direct factory sales. We will provide the most suitable quotation according to customers' requirements to ensure the highest cost - performance ratio.

Minnuo has a strong and responsive pre - sales department. As long as you have the drawings, for a single piece of equipment, we can recommend the equipment within 10 minutes. For production lines composed of multiple pieces of equipment, we will provide a solution within 5 working days!

We have complete basic production equipment. For turning and milling centers,we customize components such asmachine systems, spindle speeds, motor power, and outer shell sheet metal.

Our company has several processing mother machines from international top - tier brands, which ensures the processing accuracy of mill and turn machine components. Also, we provide a quality inspection report when the machine is dispatched from the factory.

For standard models, we keep stock and can deliver quickly. Custom models can be delivered within 30-45 working days.

Our CNC turning and milling center comes with a one-year warranty. During the warranty period, we provide free repair services. If the equipment malfunctions, customers can contact .

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763