Differences Between 3+2 Axis and 5-Axis Machining

In the field of CNC machining, choosing the right equipment is like picking the right tool for a craft — the right choice boosts efficiency, while the wrong one doubles the effort. The debate between 3+2 axis machining and 5-axis machining is a frequent one. Though both involve five axes, their performance differs significantly.

3+2 axis machining excels in static positioning, making it ideal for efficient machining of parts with fixed angles and medium complexity. In contrast, 5-axis machining offers dynamic simultaneous movement, making it the core solution for manufacturing complex curved surfaces and high-precision parts.

Let’s explore the key differences between 3+2 axis and 5-axis machining.

I. What Is 3+2 Axis Machining?

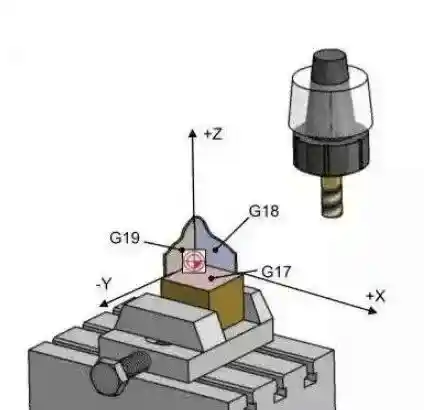

(3 axis)

Let’s start with 3+2 axis machining, which is an evolution of traditional 3-axis technology. A 3-axis machine uses X, Y, and Z movements to process flat surfaces and simple stepped geometries.

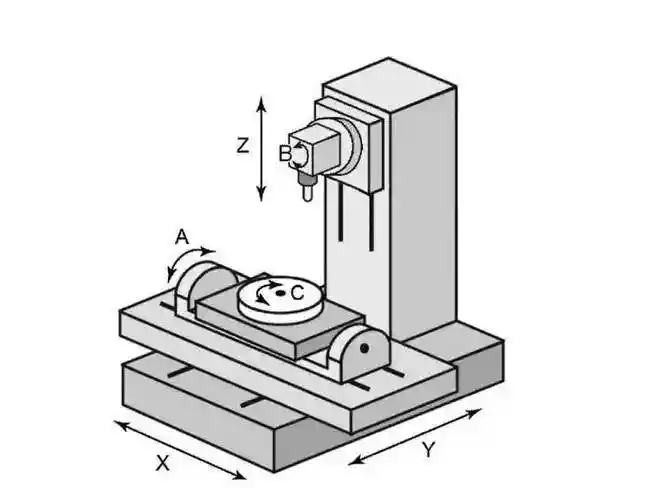

3+2 axis machining adds two rotary components — typically, an A axis that rotates around the X axis and a C axis that rotates around the Z axis.

A key characteristic of these rotary axes is that they position the workpiece before cutting begins. It’s like adjusting the camera angle before taking a picture: the machinist rotates the table to the required angle and locks it in place, and then the X, Y, and Z axes perform the cutting just like a standard 3-axis machine.

For example, to process an angled hole, the operator can rotate the worktable to 45 degrees and fix it, then use linear axes to move the tool — completing the task in one setup without multiple re-clampings.

This approach offers good cost performance and handles more angular needs than a standard 3-axis machine. However, it has limitations: for complex surfaces, multiple angle adjustments are needed, which may result in visible tool marks at seam lines.

II. What Is 5-Axis Machining?

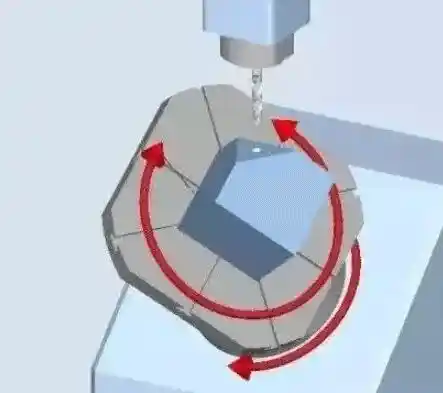

5-axis machining is a highly flexible system that also includes X, Y, and Z linear axes and two rotary axes. Its core advantage lies in all five axes working simultaneously during cutting. The rotary axes dynamically adjust angles during the cutting process according to programmed instructions, ensuring the tool always engages the workpiece at the optimal orientation.

Key Differences Between 3+2 Axis and 5-Axis Machining:

Feature | 3+2 Axis Machining | 5-Axis Machining |

Axis Movement | Rotary axes position first; then 3-axis cutting | All 5 axes move simultaneously |

Angle Adjustment Timing | Fixed before cutting; no change during | Continuously adjusted during cutting |

Curved Surface Capability | Requires multiple setups; may leave tool marks | One-pass smooth machining; no marks |

Operation Logic | Step-by-step: position → cut → reposition | Continuous, fluid operation start to finish |

Example:

When machining a propeller blade, a 5-axis machine can continuously adjust the tool angle to remain perpendicular to the surface. A 3+2 axis machine would require multiple setups, leaving visible seams where cuts from different angles meet. This highlights the essential difference between static positioning and dynamic motion.

III. Core Advantages of 5-Axis Machining

With its simultaneous multi-axis movement, 5-axis machining represents cutting-edge manufacturing technology, offering these real-world benefits:

1. Higher Machining Precision

Real-time angle adjustments maintain optimal cutting conditions:

Uniform cutting speed across the tool (eliminates speed discrepancies between tool center and edge)

Reduced tool overhang (minimizes vibration and error)

One-time setup machining (eliminates positioning errors from multiple re-clampings)

2.Capability for Complex Parts

Handles shapes that traditional machines struggle with:

No segmentation needed for parts like turbine blades

Avoids tool interference when processing complex cavities

Enables integrated part design (combining multiple functions into one part)

3. Improved Production Efficiency

Replaces multiple operations with single setup (reduces inter-machine transfer time)

Optimized tool angles reduce wear (extends tool life by ~20%)

Automated machining minimizes manual intervention (streamlines workflow)

4. Better Material Adaptability

For tough materials like titanium alloys or mold steel — or thin-walled parts — 5-axis machines can control cutting forces via angle adjustments, reducing the risk of part deformation.

V. Application Scenarios Comparison

Understanding the technical traits helps you choose the right application scenario:

Ideal Use Cases for 3+2 Axis Machining:

Mold roughing: Efficiently removes material from standard molds with fixed angles.

Box-type parts: Multi-directional hole machining (e.g., gearbox housings), minimizing setups.

Automotive parts: Mass production of parts with fixed inclined features (e.g., knuckles).

Medium-complexity parts: Moderate precision requirements, no need for 5-axis functionality.

Ideal Use Cases for 5-Axis Machining:

Aerospace parts: Complex structures with strict tolerances (e.g., engine blades, housings).

Medical instruments: Precision parts with smooth surfaces (e.g., prosthetics, surgical tools).

High-precision molds: Optical or automotive exterior molds requiring mirror finishes.

Custom art pieces: Sculptures or decorative items with freeform surfaces.

Thin-walled structures: UAV frames, aerospace parts needing deformation control.

Conclusion

3+2 axis machining is suitable for high-volume, fixed-angle applications, while 5-axis machining excels in complex, high-precision scenarios. Choosing the right technique for your specific application ensures optimal machining quality and efficiency.

If you're still undecided between a 3+2 axis or 5-axis machine for your parts, feel free to contact us at Minnuo. As a professional solution-oriented machine tool manufacturer, we look forward to learning about your specific machining needs — from part characteristics and precision requirements to production scale — and recommending the most suitable machine for you.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763