How to Adjust the Center Height of a CNC Vertical Lathe?

In precision machining, even a slight deviation in the center height can cause the entire batch of products to lose accuracy, or even halt the production line. For high-precision materials such as aerospace parts, tool steels, and carbide, any minor issue with the center height can affect the final machining quality, potentially leading to significant economic losses and equipment failures. This step is often the root cause of many production accidents, yet it is often overlooked.

Adjusting the center height of a CNC vertical lathe is critical. The key is to use precision measurement tools (such as a dial indicator or spirit level) to confirm the current height, then fine-tune it by adjusting the spindle support or tool holder height to ensure it matches the machining requirements, thereby guaranteeing machining accuracy and equipment stability.

Next, we will start by defining what center height is, then delve into its impact on machining accuracy and how to make adjustments in practice.

I. Concept and Impact of Center Height

What is Center Height?

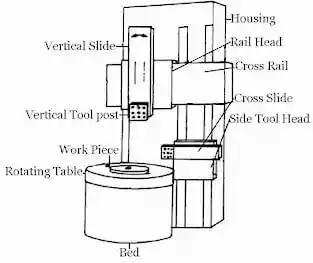

Center height refers to the vertical distance between the spindle centerline and the workpiece reference surface. This value is a key parameter that needs special attention during machine tool setup. It directly determines the relative position between the tool and the workpiece. On a single-column CNC vertical lathe, the correctness of the center height is especially important, as it affects the tool cutting angle, machining accuracy, and even tool life. Therefore, adjusting the center height must be done with great care to ensure its precision and stability.

Impact of Center Height on Machining

Machining Accuracy: If the center height is incorrect, the contact angle between the tool and the workpiece may change, leading to uneven machining or accuracy deviations. Whether it's simple turning or complex precision machining, any deviation in center height can cause dimensional errors, affecting product quality.

Tool Life: The cutting load distribution on the tool is directly influenced by the center height. If the center height is not adjusted properly, the tool may bear uneven cutting forces, leading to rapid wear or breakage, thus reducing production efficiency.

Equipment Load: Incorrect center height can increase the load on the spindle and feed system, causing unnecessary wear and tear during long-term operation and raising maintenance and part replacement costs.

Why is Adjusting Center Height So Important?

Many people might think that small deviations in center height won't cause significant machining differences, but in fact, these "slight differences" accumulate over time, often affecting machining accuracy, production efficiency, and even the stability of the equipment. Adjusting the center height is the foundation for ensuring efficient and precise production. It helps each machine stay in optimal working condition, thus saving time and costs in daily operations.

II. How to Adjust the Center Height of a Single-Column CNC Vertical Lathe?

Preliminary Preparations

The success of center height adjustment depends on meticulous preparation. Each step must ensure accuracy to avoid failure or compromise of subsequent adjustments due to insufficient preparation.

Check the Machine Condition: Before starting any operations, ensure that the spindle is free from looseness, and the guide rails are clean and well-lubricated. Check that all key components of the machine are functioning properly to avoid any interference with the adjustment process.

Prepare Measuring Tools: Precision measuring tools are key to achieving accurate adjustments. Generally, internal and external micrometersand digital spirit levels will help you measure the machine's level and center height precisely.

Consult the Operation Manual: The structure and adjustment methods for each CNC vertical lathe may differ. Therefore, consult the machine's operation manual and technical documentation from the manufacturer to ensure adjustments are made according to the manufacturer's recommended standards.

Adjustment Steps

When adjusting the center height of a CNC vertical lathe, the operation steps must be precise to avoid errors caused by improper actions. The detailed adjustment process is as follows:

Step 1: Remove the Workpiece and Tool

Before starting the adjustment, remove the workpiece and tool from the spindle to ensure the machine is in an unloaded state. This helps avoid interference from external forces during the adjustment process.

Step 2: Use a Spirit Level to Confirm Machine Level

Before adjusting the center height, confirm whether the machine is level. Use a spirit level to calibrate the machine base for horizontal alignment. If the machine is tilted, the adjustment result will be inaccurate, affecting subsequent machining precision.

Step 3: Measure the Current Center Height

Use a micrometer or other precision tools to measure the current center height. If there is a deviation, further adjustments are needed.

Step 4: Adjust the Center Height

This step is the core of the operation. Adjust the spindle support or tool holder height according to the machine's design. For manual machines, this is usually done by rotating adjustment screws. For machines with an electric adjustment system, fine-tuning can be done using the control panel.

Step 5: Recheck

After making adjustments, it is best to perform two or even three confirmation checks to ensure the accuracy of the center height. Use a micrometer to measure again, and also use the spirit level to check the machine's level, ensuring no errors have occurred.

Important Notes

Ensure Tool Accuracy: Any error in precision tools can affect the adjustment result. Regularly calibrate measuring tools to ensure their accuracy.

Avoid Over-Adjustment: During the adjustment process, avoid over-adjusting. Each adjustment should be small and precise, with gradual fine-tuning until the required accuracy is reached.

Check Post-Adjustment Machining Results: After the adjustment is complete, perform some simple test machining to check the machining accuracy and surface quality of the workpiece to ensure the adjustment's effectiveness.

III. Common Issues and Solutions

Center Height Still Deviates After Adjustment

Sometimes, even after adjustments, the deviation cannot be eliminated. The following reasons may apply:

Spindle or Tool Holder Damage: If the machine’s spindle or tool holder is worn or damaged, adjusting the center height may not completely eliminate the error. In this case, consider replacing the components.

Improper Operation: Improper operation or inaccurate use of measuring tools during the adjustment may also lead to failure. It is recommended to recheck the adjustment steps and perform careful checks.

Unbalanced Phenomenon During Center Height Adjustment

If an imbalance is found during the adjustment process, it may be due to improper installation or vibrations. In this case, check the machine's stability again or reinstall the spindle to solve the problem.

IV. Conclusion

To ensure long-term efficient production, it is recommended to regularly maintain and inspect the machine. Center height adjustment is not just a technical operation; it reflects ongoing attention to the machine's precision. If you encounter any difficulties or unsolved issues during the adjustment process, feel free to contact Minnuo. Our professional team will provide you with free technical support and solutions to ensure that your equipment remains in optimal working condition, improving production efficiency.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763