How to Choose the Most Suitable Cutting Tool for Your Machine Tools?

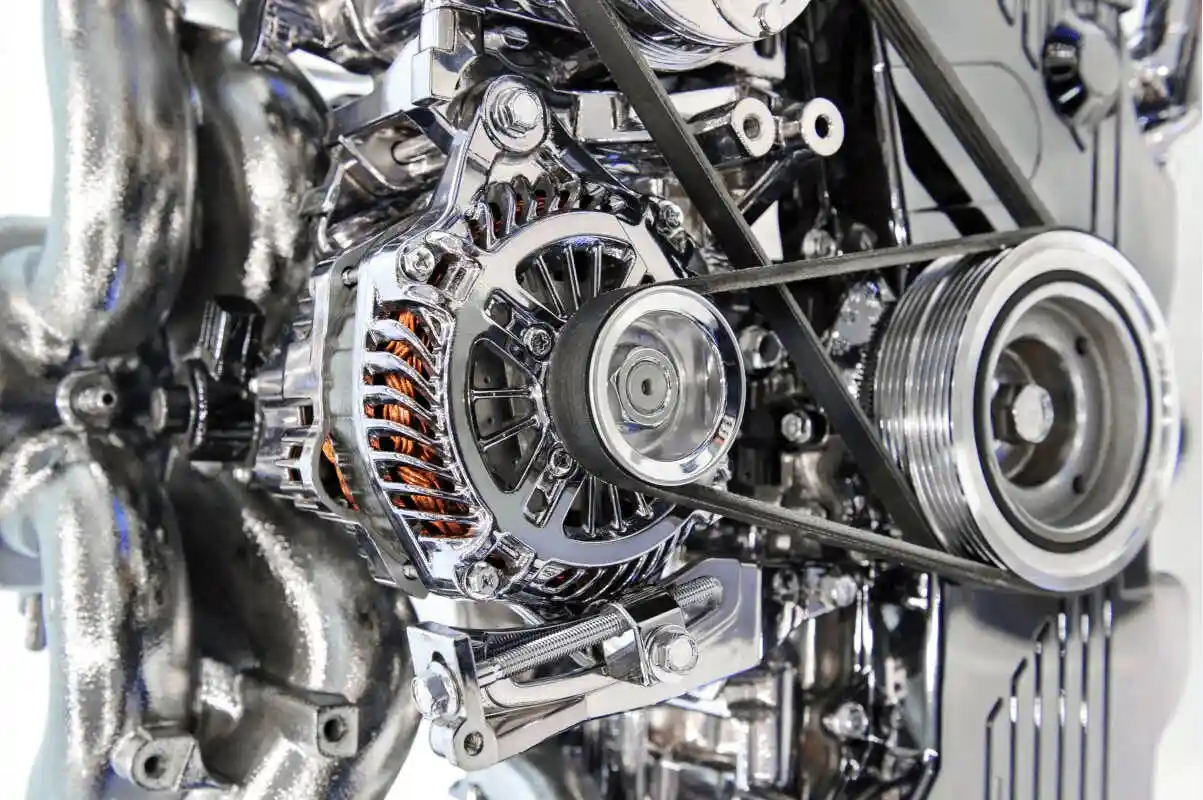

In mid-June, the $19 billion auto parts supplier Magneti Marelli announced its bankruptcy filing. Despite its significant position in the automotive industry, Magneti Marelli failed to adjust its strategy and optimize production methods in time, leading to a financial crisis. This incident serves as a reminder that making the right choices is crucial in both corporate strategy and day-to-day operations. In manufacturing, choosing the righ cutting tool for your machine tools is equally a key factor in determining production efficiency, product quality, and a company’s competitiveness.

Choosing the right cutting tool requires considering factors such as workpiece material, tool material and coating, tool geometry, and cutting conditions. By matching these factors, production efficiency can be improved, costs reduced, and tool life extended, ensuring processing quality.

Now, let's explore the most suitable cutting tool types for you.

1. Types of Cutting Tool

Milling Cutters:

Face Milling Cutter: Used for surface milling, suitable for large-area milling, commonly found in the automotive and aerospace industries.

End Mill: Used for milling slots, contours, and other fine processing, suitable for high-precision work.

Slot Cutter: Suitable for cutting narrow grooves, commonly used in mold manufacturing.

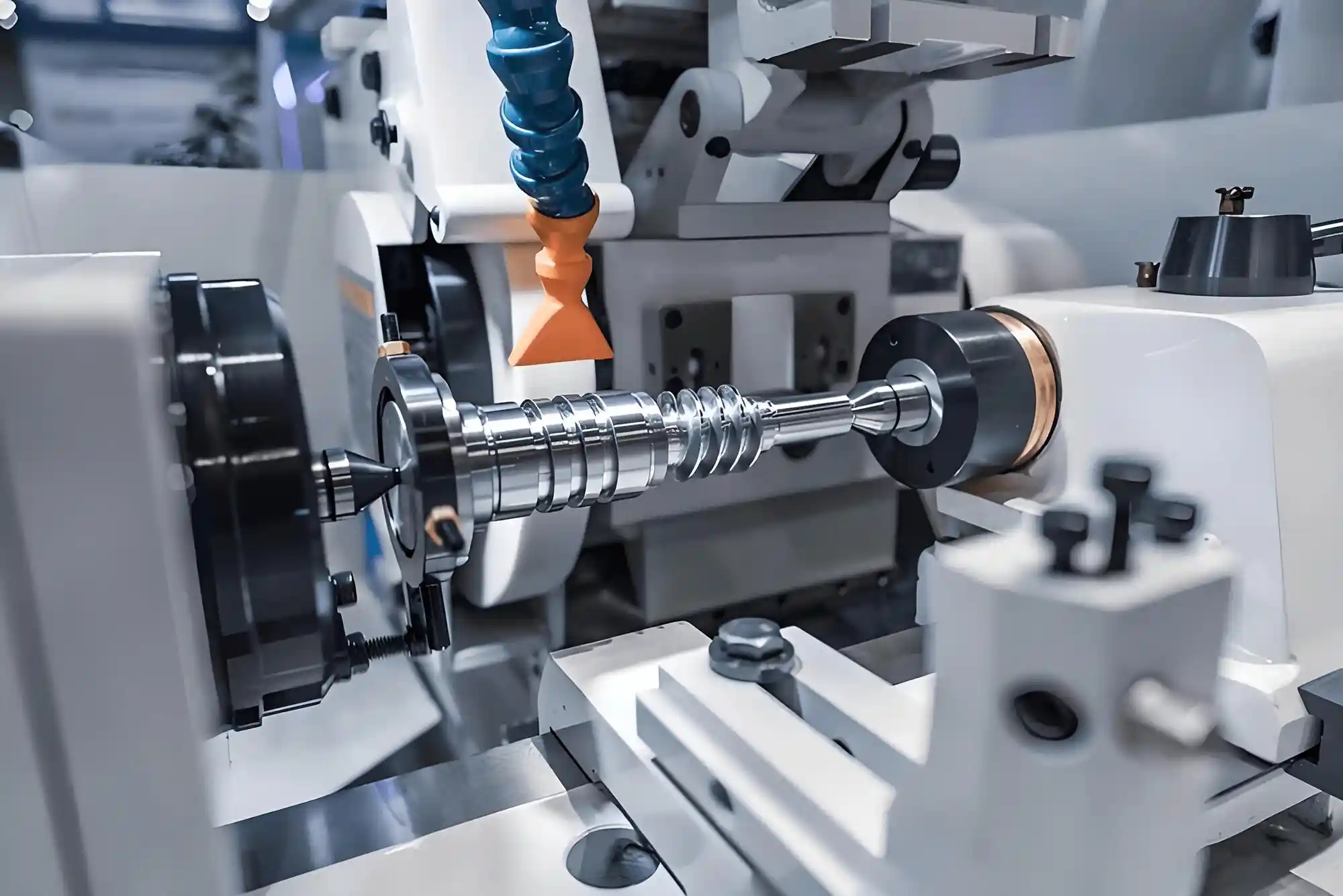

Turning Tools:

External Turning Tool: Mainly used for turning the outer diameter of a workpiece, widely used in shaft parts.

Internal Turning Tool: Used for turning the inner holes of workpieces, ensuring the dimensions and precision of the internal holes.

Parting Tool: Specially used for cutting workpieces, especially in mass production, offering high efficiency.

Drills:

Drills are common tools in manufacturing, and almost every industry relies on them. Did you know that choosing different types of drills can greatly improve processing efficiency?

Drills are common tools in manufacturing, and almost every industry relies on them. Did you know that choosing different types of drills can greatly improve processing efficiency?Twist Drill: A common multi-functional drill bit, suitable for general hole processing.

Spade Drill: Suitable for high-load deep hole drilling, offering stronger cutting forces.

Special Shape Drill: Such as center drills, deep hole drills, and others, effective for special needs.

Grinding Tools:

Sometimes, we need not only precision but also a smooth surface. Grinding tools help us achieve this.Grinding Wheels:

Flat Grinding Wheel: Mainly used for surface grinding, suitable for large-area workpiece surface processing, widely used in metal cutting and mechanical parts processing.

Form Grinding Wheel: Used for grinding special shapes, such as outer circles, inner holes, and curved surfaces, particularly important in precision part processing.

High-Speed Grinding Wheel: Suitable for high-speed grinding, commonly used in high-precision and rapid material removal processes.

Grinding Stones (Grindstones):

Grinding stones are common hand-held grinding tools, typically used for manual or small-batch fine grinding. They are useful for removing surface imperfections, smoothing surfaces, or removing rust. Grinding stones can be selected based on hardness, suitable for grinding different materials.Grinding Belts:

Grinding belts are commonly used for detail polishing and removing small surface defects of workpieces. Their advantage lies in providing a uniform grinding effect, widely applied in polishing materials such as aluminum and stainless steel.Specialized Tools:

Forming tools are specially used for making parts with specific shapes, such as gears and threads, and are essential for precision parts.Gear Cutting Tools: Used for gear processing, ensuring gear meshing accuracy and operational stability.

Thread Tools: Used for cutting internal and external threads, meeting high-precision requirements.

2. Factors to Consider When Choosing Cutting Tools

Workpiece Material:

First, understanding the material of the workpiece is a key step in choosing the right tool. Different materials require different tools, which directly affects cutting efficiency and the final result.Steel: Carbide tools are suitable for high-strength cutting of steel, offering higher wear resistance.

Aluminum Alloy: High-speed steel tools or coated tools are commonly used for aluminum alloy processing, improving processing speed and extending tool life.

Titanium Alloy: Due to its high hardness, titanium alloy requires ceramic or carbide tools.

Plastic: High-speed steel tools are typically used for plastics as their cutting requirements are relatively low.

Cutting Tool Material:

Different tool materials have different characteristics, and understanding their pros and cons is fundamental to choosing the right tool.Carbide: Carbide tools are highly reliable for high-speed cutting. They are heat-resistant and wear-resistant, making them ideal for high-speed machining.

High-Speed Steel (HSS): If you're working on low-load, low-speed tasks, high-speed steel tools are ideal, offering good toughness for various medium and low-speed cutting tasks.

Ceramic Tools: Ceramic tools are excellent for high-speed cutting, especially in processing hard materials. They provide outstanding cutting performance when machining very hard materials.

Diamond Tools: For machining ultra-hard materials, diamond tools are very suitable, especially in ultra-precision processing in the semiconductor industry.

Cutting Tool Geometry:

The geometry of the tool directly impacts cutting performance. Different cutting angles and tool shapes help you achieve the best results during processing.Cutting Edge Angle: Affects cutting force and surface quality. For example, a larger rake angle reduces cutting force but may affect tool life.

Point Angle: The point angle of drills affects hole quality and drilling speed. A smaller point angle is suitable for deep hole drilling, while a larger point angle is better for precision drilling.

Cutting Conditions:

When choosing tools, cutting conditions are crucial in determining tool life and machining efficiency.Cutting Speed and Feed Rate: Higher cutting speeds are suitable for hard materials or high-production-efficiency machining. The feed rate is chosen based on the workpiece material and tool durability.

Cutting Depth: A larger cutting depth may increase tool wear, so selecting tools with stronger wear resistance is necessary.

By optimizing tool geometry, you can achieve more efficient and stable machining.

3. Which Tools Are Best for Which Industries?

Tool Type | Applicable Industries | Application Areas |

Milling Cutter | Automotive, Aerospace, Molding | Used for face milling, end milling, slot milling, etc. |

Turning Tool | Metalworking, Automotive, Heavy Machinery | Mainly used for turning outer diameters, inner holes, and cutting operations, widely used in shaft parts production. |

Drill | Mechanical Processing, Electronics, Aerospace | Used for hole operations, widely used in metal, plastic, and other workpiece hole machining. |

Grinding Tool | Precision Machining, Automotive, Metal Manufacturing | Used for fine grinding of surfaces, improving workpiece surface quality and precision. |

Forming Tool | Molding, Gear Manufacturing, Aerospace | Used for processing specific shapes and precision parts, commonly used in gear and thread processing. |

Indexable Tool | Mass Production, Mechanical Manufacturing, Automotive | Widely used in high-efficiency, mass production, reducing tool change time, and increasing production efficiency. |

4. Tool Life and Wear Considerations

Understanding Tool Wear:

Tool wear is an inevitable phenomenon in any cutting process. As tools wear out during use, their cutting performance gradually declines, affecting machining accuracy, surface quality, and production efficiency. Overworn tools not only reduce cutting efficiency but may also lead to production stoppages and unstable quality. Therefore, timely detection of wear and replacement of tools are key to improving production efficiency and maintaining product quality.Signs of Wear:

How can you determine when to replace a tool? Here are common signs of wear:Increased Cutting Force: During processing, greater force is needed to push the tool, indicating that the tool may be worn.

Surface Quality Decline: If the workpiece's surface roughness fails to meet requirements, the tool's cutting edge may be worn.

Increased Heat: Tool overheating or smoke may be due to excessive wear, as friction generated during cutting becomes too high.

Dimensional Out-of-Spec: If the processed workpiece's dimensions no longer meet requirements, it is often due to the tool’s wear causing inaccurate cutting.

Recognizing these signs and replacing tools in time can avoid issues during processing, ensuring product quality and production efficiency.

Tips to Extend Tool Life:

Tool wear is unavoidable, but there are some techniques to extend tool life:Optimize Cutting Parameters: Properly setting cutting speed, feed rate, and cutting depth can reduce tool wear. Lower cutting speeds can reduce friction, thereby extending tool life.

Choose the Right Tool Material: Select the appropriate tool material based on the characteristics of the workpiece material. For example, carbide tools are suitable for hard material processing, while high-speed steel is suitable for general metal machining.

Use Coolants Properly: Using coolants can effectively reduce cutting temperatures and minimize tool wear.

Regular Maintenance and Care: Regularly check tool conditions and avoid using the same tool for extended periods. Timely sharpening or dressing can help extend tool life.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763