How to Correctly and Safely Start and Commission a New CNC Machine

When you first acquire a new CNC machine, there’s a sense of both excitement and apprehension — worried about operating it incorrectly and potentially impacting the machine's performance, or even creating safety hazards.

Before starting up and commissioning a new CNC machine, it’s crucial to first inspect the machine’s appearance, power supply voltage, and lubrication system. Only once everything checks out should you proceed to start the machine. During commissioning, safety must be a priority, and it's essential to configure parameters correctly, while also properly installing the tools and workpieces.

Here’s a detailed guide on the specific steps and precautions to take to help you get your new machine up and running with ease.

I. Pre-startup Preparations for a New CNC Machine

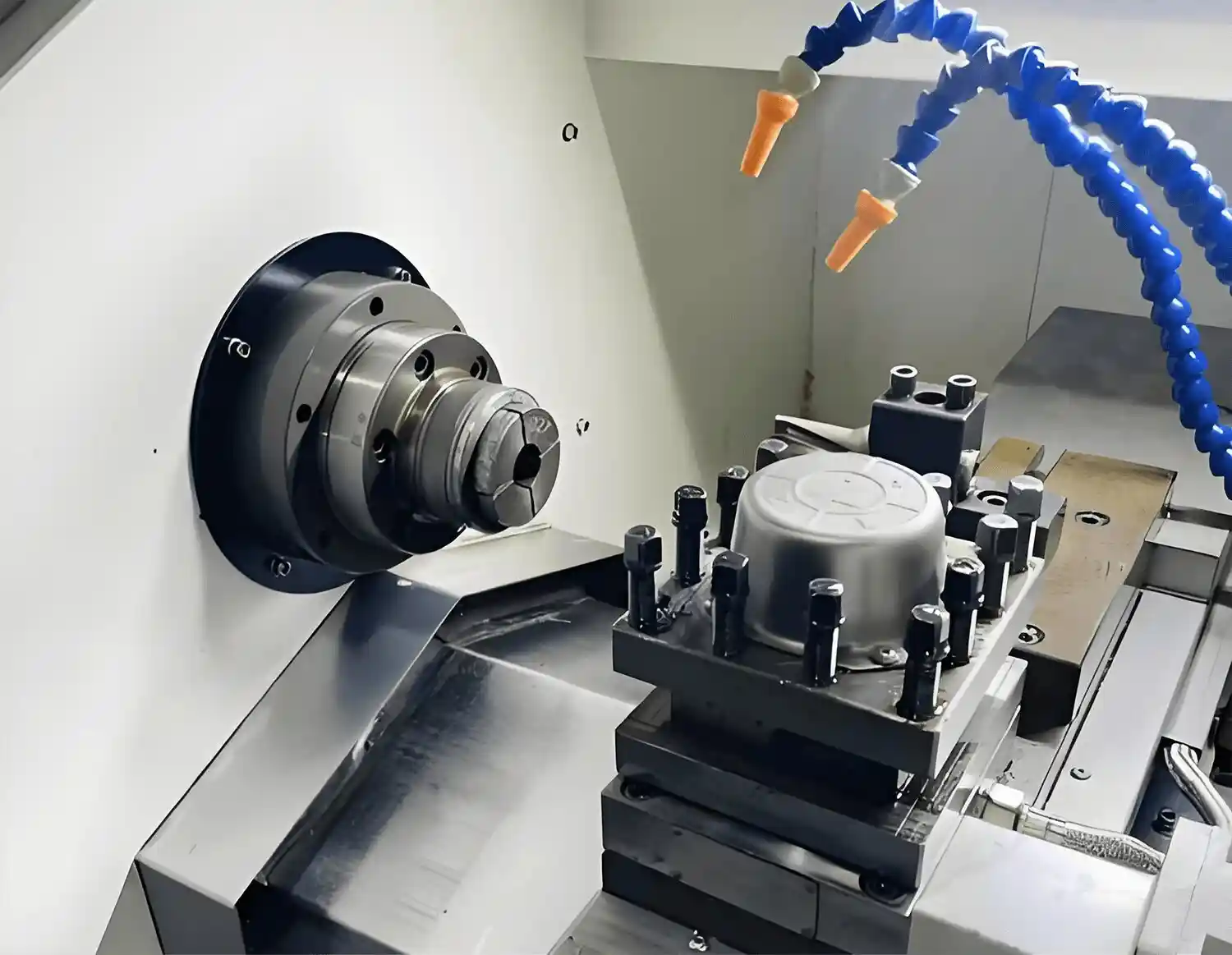

(Slant bed CNC Lathe)

The preparatory work before starting a CNC machine has a direct impact on the machine’s operational state. By following these steps, you can identify potential issues early and avoid unnecessary wear and tear.

Conduct a Thorough Visual Inspection of the Machine

Examine the machine's exterior for any damage, such as dents or deformations that may have occurred during transportation.

Check that all connections are secure. Open the protective doors to inspect the internal components, such as rails and ball screws, ensuring there are no foreign objects, particularly metal shavings or dust.

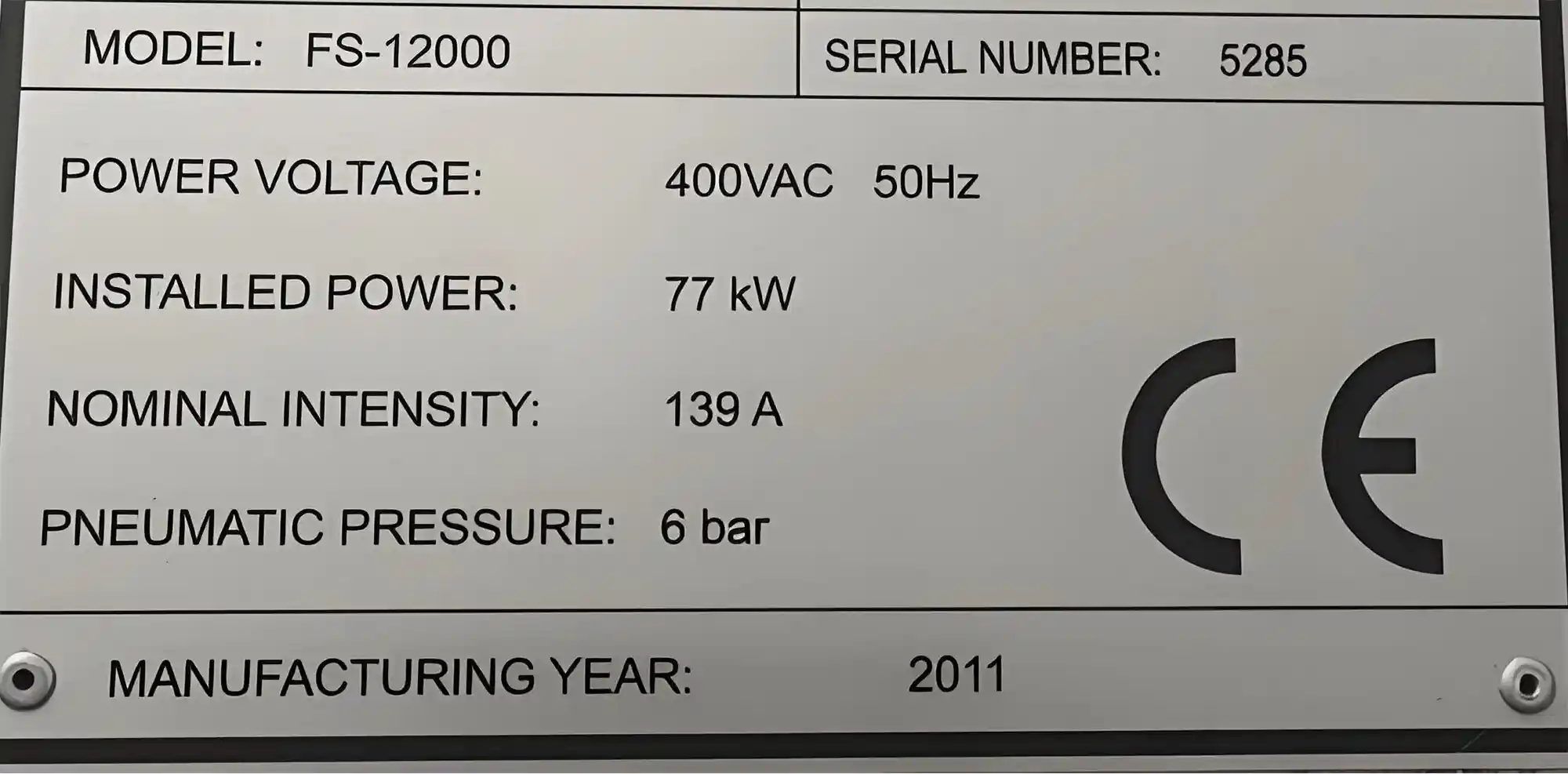

Check the Power Supply Voltage

CNC machines have strict voltage requirements.

Verify that the power supply voltage matches the machine's rated voltage, typically indicated on the machine’s nameplate(common values are 220V or 380V).

Use a multimeter to measure the actual voltage, ensuring it falls within the allowable range for the equipment.

Lubrication System Inspection

Check the oil level to ensure it is within the recommended range, adding oil if necessary.

Ensure the oil pathways are clear and that each axis is lubricated properly. For the initial use, manually pump oil several times.

II. Correct Startup Procedure for a New CNC Machine

Once you’ve completed the preparations, you can proceed with starting the machine.

Power On in Sequence

Turn on the main power switch and wait for 30 seconds to allow the power supply to stabilize. Then, turn on the CNC machine’s operation panel power.

If the machine has an emergency stop button, make sure it is in the “release” position before starting.

Observe the Following During Startup

Listen for sounds: A normal startup should produce a steady, low noise. If you hear sharp, abnormal sounds or grinding noises, immediately power down and inspect the machine.

Check the indicator lights: The power light and system startup light should light up sequentially. If any light flickers or does not turn on, refer to the manual for troubleshooting.

Functional Testing After Startup

Test all functional buttons to ensure they work properly, such as the spindle start/stop and manual control of the feed axes.

Observe the motion of the spindle and feed axes to ensure they move smoothly. Let the spindle run idle for 3-5 minutes and check if the rotation speed remains stable.

III. Safe Commissioning

The commissioning stage is key for ensuring the machine’s performance. It’s important to prioritize safety while configuring the machine’s parameters accurately to ensure parts are processed to specification.

Safety First

Even with years of experience, never overlook safety precautions during commissioning:

Even with years of experience, never overlook safety precautions during commissioning:

Operators must wear safety goggles, non-slip footwear, and keep long hair tied up and covered.

Do not extend your hands into the machining area while the machine is running, and never open protective doors casually.

Before running new programs, perform a dry run to ensure the tool path is correct, then load the workpiece.

Parameter Settings

Different materials and processes require different parameter settings. Follow these two steps to configure the machine more effectively:

Parameter | Setting Criteria | Validation Method |

Spindle Speed | Material hardness, tool type | Measure actual spindle speed with a tachometer during idle run |

Feed Rate | Required machining accuracy, tool diameter | Measure surface roughness after trial cut |

Cutting Depth | Tool strength, workpiece material | Observe cutting for vibrations |

After setting the parameters, it is advised to back up the settings to avoid accidental deletion later.

Tool and Workpiece Installation

Correct tool and workpiece installation directly affects machining quality and safety:

Tool Selection: Choose the appropriate tool based on the material being processed. For aluminum, use high-speed steel tools, and for steel, opt for carbide tools.

Installing Tools: After inserting the tool into the tool holder, tighten the screws evenly with a wrench to prevent any looseness. Keep the tool extension as short as possible to reduce vibrations.

Clamping the Workpiece: Clean the workpiece's bottom surface and ensure the clamping force is evenly distributed to prevent deformation. Small workpieces can be clamped using a vice, while large workpieces should be secured with clamping plates.

IV. Common Issues During Startup and Commissioning

When facing machine malfunctions, follow these steps to troubleshoot. Most minor problems can be resolved on your own.

What to Do if Startup Fails?

Possible Causes: Power supply issues, wiring faults, or internal machine faults.

Solution: Check that the power is on and inspect for loose wiring connections, especially at the power input terminal. If everything appears normal but the issue persists, the internal circuit may be faulty, requiring technical support from the manufacturer.

What if There’s Abnormal Noise During Operation?

Possible Causes: Insufficient lubrication, loose parts, or bearing damage.

Solution: Add the appropriate type of lubricant, focusing on the rails and ball screws. Tighten any loose components and torque them as specified. If the noise originates from the spindle, bearing wear could be the issue, and the spindle may need to be replaced.

What to Do if the Machining Accuracy is Inadequate?

Possible Causes: Incorrect parameter settings, tool wear or installation issues, or unstable workpiece clamping.

Solution: Adjust parameters, ensuring the feed rate and spindle speed are properly matched. Replace worn tools or recalibrate the installation. Reinforce workpiece clamping to ensure even force distribution.

V. Daily Maintenance is Also Crucial

Clean the machine regularly by removing chips and oil after each shift, and use compressed air to blow out dust from control panels every week.

Monthly, check that all components are tightened, particularly tool holders and worktable screws.

Replace lubricants as per the machine’s manual, lubricating the rails after every shift and changing the spindle bearing grease every six months.

Conclusion

Correctly starting, commissioning, and maintaining a new CNC machine at the beginning will lay the foundation for stable long-term operation. By following the steps outlined above, you can ensure both safety and effective performance.

For those new to commissioning and installation,Minnuo offers comprehensive services — from machine selection to professional installation and commissioning — so you don’t need to worry about technical issues.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763