Regular maintenance

Max. Workpiece Length: 530–1000mm · Swing Ø440–500mm · Spindle Bore Ø38–51mm

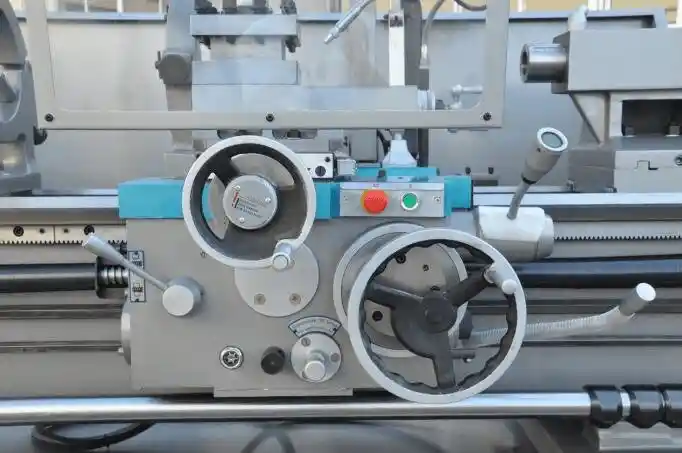

The CZ1224G-CZ1440G/1 Series is a cost-effective manual lathe designed for general turning, education, and light-duty production. With swing diameters of 440mm to 500mm and workpiece lengths of 530mm to 1000mm, it offers reliable performance in a compact and affordable package.

CZ1224G-CZ1440G/1 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Flexible Size Options: Choose between multiple models with different work lengths (530mm to 1000mm) and saddle swing diameters (440mm to 500mm).

- ● Wide Spindle Bore (Ø38mm–Ø51mm): Suitable for machining of small hollow shafts, pipes, or rod stock.

- ● Precision Gear Head Spindle: Delivers smooth power transmission and stable cutting performance.

- ● Compact, Efficient Layout: Ideal for small workshops, school labs, and maintenance rooms with limited space.

- ● Easy-to-Operate Manual Controls: Straightforward levers, dials, and feed gears for beginner to skilled users.

Recommended Configurations

- ● Spindle: High-precision spindle (SKF, NSK)

- ● Chuck: Three-jaw chuck with chuck protection device, manual four-jaw independent chuck

- ● Drive System: Belt drive, motor drive

- ● Turret: Single turret, square tool post

- ● Cooling System: Conventional cooling system, built-in cooling system

- ● Support: Stable support, follow rest

- ● Other Configurations: Center rest, protective cover design, manual tailstock, work light

Application Case

- ● Client: Technical training college (Southeast Asia).

- ● Use Case: Hands-on machining education + light-duty repair work.

- ● Setup: CZ1340G with standard 3-jaw chuck, tool post, and thread dial.

- ● Results: Used to teach turning, facing, threading, taper machining, Required minimal maintenance with over 1,000 training hours/year, ±0.03 mm repeatability achieved in student machining tasks, Extremely popular due to ease of use and affordable price.

Product Specifications

| Parameters | unit | CZ1224G | CZ1324G | CZ1237G | CZ1337G | CZ1340G | CZ1440G | CZ1237G/1 | CZ1337G/1 | CZ1340G/1 | CZ1440G/1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Swing over bed | mm | 305 | 330 | 305 | 330 | 330 | 350 | 305 | 350 | 330 | 350 |

| Swing over carriage | mm | 173 | 195 | 173 | 215 | 195 | 220 | 173 | 215 | 195 | 220 |

| Swing over gap | mm | 440 | 465 | 440 | 485 | 476 | 500 | 440 | 485 | 476 | 500 |

| Width of bed-way | mm | 182 | 182 | 186 | 182 | 186 | 186 | ||||

| Distance between centers | mm | 530 | 940 | 1000 | 940 | 1000 | 1000 | ||||

| Spindle taper | MT5 | MT5 | MT5 | MT5 | MT5 | MT5 | |||||

| Spindle bore | mm | 38 | 38 | 38 | 38 | 38/51 | 38/51 | ||||

| Step of speed | 9 | 9 | 8 | 9 | 8 | 8 | |||||

| Range of speed | rpm | 64-1500 | 64-1500 | 70-2000 | 64~1500 | 70-2000 | 84-1850 | ||||

| Metric thread | mm | Closed box:11kinds(0.5~43.5) | Closed box:11kinds(0.5~43.5) | 23kinds(0.25-11) | 26kinds(0.4~7) | 26 kinds(0.4-7) | 26 kinds(0.4-7) | ||||

| Norton box:15kinds(0.25~47.5) | Norton box:15kinds(0.25~47.5) | ||||||||||

| inch thread | T.P.I | Closed box:14kinds(7-1/2~48) | Closed box:14kinds(7-1/2~48) | 40 kinds(4-112) | 34kinds(4~56) | 34 kinds(4-56) | 34 kinds(4-56) | ||||

| Norton box:40kinds(4~112) | Norton box:40kinds(4~112) | ||||||||||

| Range of feed rates | Mm/r | Closed box:0.051~0.303 (0.002''-0.012'') | Closed box:0.051~0.303 (0.002''-0.012'') | 0.091-2.533 (0.0036''-0.1005'') | 0.052-1.392mm/r (0.002-0.0548) | 0.052- 1.392(0.002"-0.0548") | 0.091- 2.533(0.0036-0.1005") | ||||

| Norton box:0.12~0.42 (0.0047''-0.0165'') | Norton box:0.12~042 (0.0047''-0.0165'') | 0.025-0.69 (0.0012'-0.0345) | 0.014-0.38mm/r (0.00055-0.015) | 0.014- 0.38(0.00055"-0.015") | 0.025- 0.69(0.0012"-0.0345) | ||||||

| Diameter of lead screw | mm | 22(7/8'') | 22(7/8'') | 22 | 2222(7/8°) | 22 | 22 | ||||

| Pitch of lead screw | / | 3mm or 8 T.P.I | 3mm or 8 T.P.I | 3mm or 8 T.P.I | 3mm or 8T.PI | 3mm or 8 T.P.I | 3mm or 8 T.P.I | ||||

| Saddle travel | mm | 510 | 510 | 1000 | 810 | 1000 | 1000 | ||||

| Cross travel | mm | 150 | 150 | 170 | 150 | 170 | 160 | ||||

| Compound travel | mm | 85 | 85 | 74 | 85 | 74 | 70 | ||||

| Barrel travel | mm | 95 | 95 | 95 | 95 | 95 | 95 | ||||

| Barrel diameter | mm | 32 | 32 | 32 | 32 | 32 | 32 | ||||

| Taper of center | mm | MT3 | MT3 | MT3 | MT3 | MT3 | MT3 | ||||

| Motor power | Kw | 1.1(1.5HP) | 1.1(1.5HP) | 1.5(2HP) | 1.1(1.5HP) | 1.5(2HP) | 1.5(2HP) | ||||

| Coolant motor | Kw | 0.04(0.055HP) | 0.04(0.055HP) | 0.04(0.055HP) | 0.04(0.055HP) | 0.04(0.055HP) | 0.04(0.055HP) | ||||

| Machine(L×W×H) | mm | 1420x750x760 | 1420x750x760 | 1920x750x760 | 1780×750x760 | 1920x760x760 | 1920x760x760 | ||||

| Stand(left)(LxWxH) | mm | 400x370x700 | 400x370x700 | 440x410x700 | 400×370x700 | 440x410x700 | 440x410x700 | ||||

| Stand(right)(L×W×H) | mm | 300x370x700 | 300x370x700 | 370x410x700 | 300×370x700 | 370x410x700 | 370x410x700 | ||||

| Machine(N.W/G.W) | Kg | 380/430 | 380/430 | 495/555 | 390/440 | 505/565 | 505/565 | ||||

Catalog

Frequently Asked Questions

A manual lathe can process various types of materials, including steel, cast iron, non - ferrous metals, and some non - metallic materials.

The machining accuracy of our manual lathe can reach grade IT7, which can meet the processing requirements of most precision parts.

As a professional manual lathe manufactor, Minnuo offers direct factory sales. We will provide the most suitable quotation according to customers' requirements to ensure the highest cost - performance ratio.

The pre - sales department of Minnuo Company is strong and responsive. As long as you have the drawings, for a single piece of equipment, we can recommend the best manual lathe within 10 minutes. For a production line composed of multiple pieces of equipment, we will provide a solution within 5 working days!

Minnuo Company has a complete set of basic production equipment. We can provide customization services for machine systems, spindle speeds, motor powers, and even the sheet metal of the outer shell.

Our company has several processing master machines of international first - tier brands, which ensures the processing accuracy of manual lathe machine components. At the same time, we also provide a quality inspection report when the machine leaves the factory.

We have inventory for conventional models of manual lathes and can deliver them quickly. For customized models, delivery can be made within 30 - 45 working days.

Our high precision manual lathe comes with a one - year warranty. During the warranty period, we provide free repair services. If the equipment malfunctions, customers can contact our after - sales team at any time. We provide 24 - hour technical support services and can quickly solve problems through remote video, phone calls, or on - site services.

Operating a manual lathe can be challenging for beginners, as it requires hands-on skills and precision. A skilled manual lathe operator must understand tooling, feeds, speeds, and material behavior. However, with proper training and practice, the learning curve becomes manageable.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763