How to Deal with the Impact of High Temperature on Machine Tools?

In regions such as the Middle East, South America, and Africa, extreme high-temperature events have become the norm due to climate change and the intensification of global warming, especially in summer. The temperatures in these regions have far surpassed historical levels, posing significant challenges to local industries, agriculture, energy, and other sectors.

The operational challenges of machine tools in high-temperature environments need to be understood and addressed from multiple dimensions. Whether it’s optimizing the working environment, strengthening the cooling system, or scientifically and reasonably maintaining equipment, details are crucial to the long-term stability of machine tools.

Next, we will delve into the specific impact of high temperatures on machine tool performance and explore effective measures for optimization.

1. Why Does High Temperature Affect Machine Tool Performance?

With the rise in global temperatures, many machine tool operating environments are now exposed to high-temperature conditions. The impact of high temperatures on machine tools is not superficial—it profoundly affects the operation of various systems and overall performance. We can understand this through the following aspects:

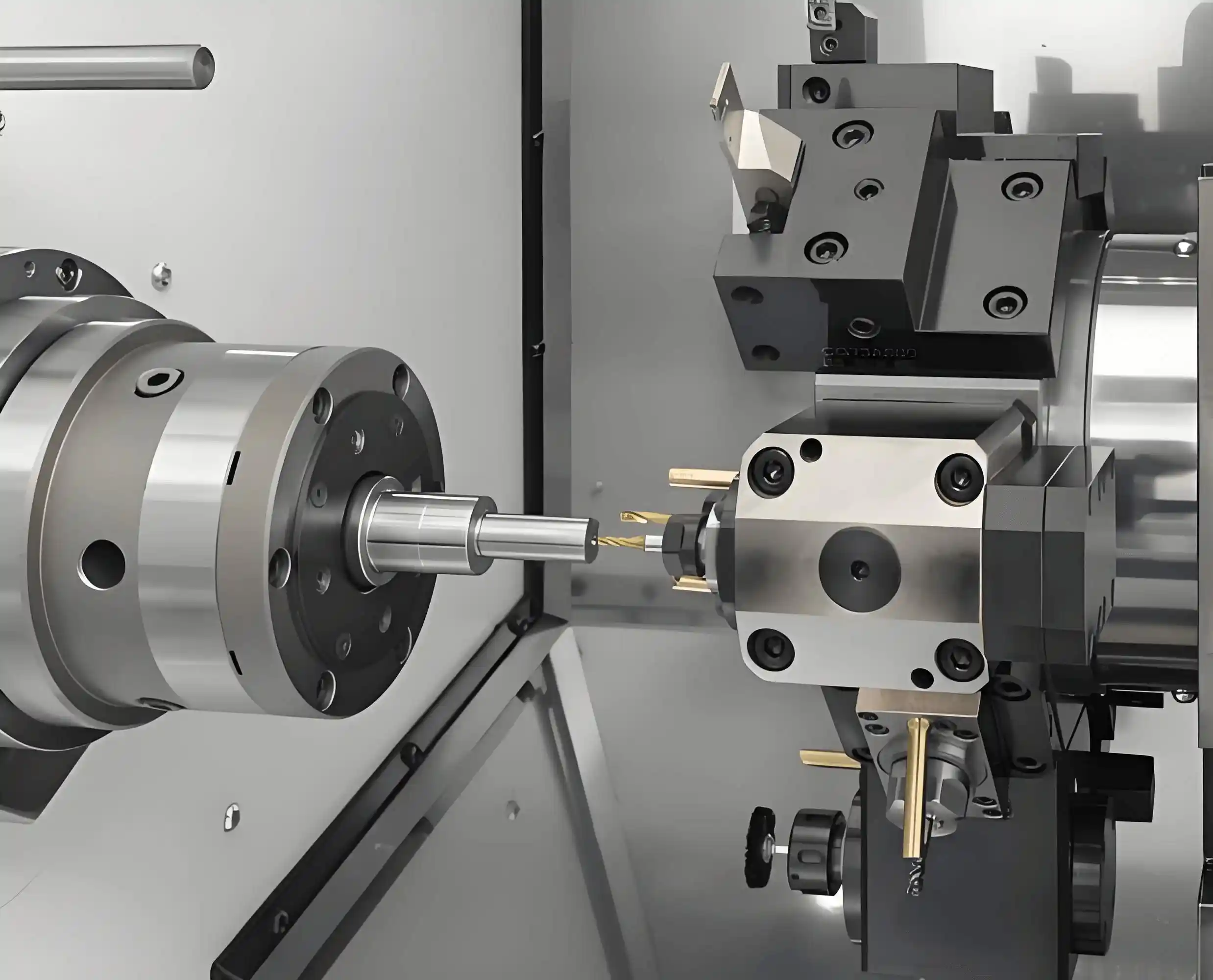

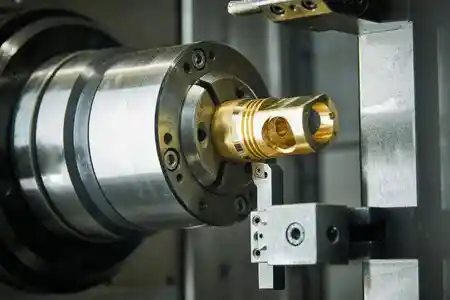

Thermal Expansion of Metal Materials: The main structure of machine tools (such as guide rails, worktables, spindles,ball screws, etc.) is made of metal materials. Under high temperatures, these metal components undergo thermal expansion, which in turn affects the precision and stability of the machine tool.

Decline in Lubricant Performance: High temperatures cause a reduction in the viscosity of lubricants, leading to decreased lubrication efficiency, which increases friction and wear.

Cooling System Failure: In high-temperature environments, the cooling liquid’s ability to cool down is limited, causing excessive temperature in key components like the spindle and worktable, which affects processing accuracy.

Overheating of Electronic Equipment: Electronic components like CNC systems, servos, and sensors are highly sensitive to temperature. High temperatures may cause these systems to fail, affecting the operation of the entire machine tool.

These four aspects are the fundamental impacts of high temperature on machine tool performance, and we must understand them in depth to formulate effective solutions.

2. Impact of High Temperature on Machine Tool Performance: Specific Manifestations

The effects of high temperature are not isolated but systemic. It not only affects the basic performance of machine tools but also threatens production efficiency, workpiece quality, and even worker safety.

1. Loss of Dimensional Accuracy

Cause: Thermal expansion of metal parts causes slight deformation of guide rails, worktables, and other components.

Result: Prolonged loss of accuracy leads to workpiece dimensional errors, severely impacting production quality.

Solution: The machine tool with thermal compensation technology, using Finite Element Method (FEM) for real-time simulation of temperature distribution and thermal displacement, compensates for errors caused by thermal expansion. This optimizes design and control systems, ensuring temperature changes do not cause dimensional errors, enhancing thermal stability and precision while avoiding costly design modifications.

2. Decline in Lubrication Effectiveness

Cause: High temperatures reduce the viscosity of lubricants and accelerate oxidation.

Result: Poor lubrication increases friction, accelerating wear on machine tool components.

Solution: Choose lubricants with strong high-temperature resistance and regularly replace them based on usage.

3. Reduced Cooling System Efficiency

Cause: High temperatures lower the cooling liquid’s ability to dissipate heat.

Result: Overheated components like spindles may lead to reduced machining precision or even machine tool damage.

Solution: Regularly check the cooling system, increase coolant flow, and use high-efficiency cooling liquids.

4. Overheating of Electronic Systems Causing Failures

Cause: CNC systems, servos, sensors, and other electronic components are sensitive to temperature.

Result: Overheating causes electronic components to fail or become unstable.

Solution: Use electronic systems with temperature control functions to ensure automatic adjustments or shutdowns when overheating occurs.

5.How High Temperature Affects Tool Life

Result: Increased tool wear not only affects processing accuracy but also necessitates frequent tool replacements, leading to higher production costs and downtime.

Solution:Use tool materials such as carbide and high-speed steel, and implement advanced cooling technologies, such as high-pressure cooling systems, to reduce the temperature rise between the tool and the workpiece, thereby extending tool life. Additionally, regularly inspect and replace tools to ensure processing quality and production efficiency.

3. How to Optimize Machine Tool Operation in High Temperature?

Since high temperature has such a negative impact on machine tool performance, how should we operate machine tools in such environments? Below are specific measures and operational considerations to help minimize the impact of high temperatures.

Workshop Environment Management

Measure | Goal | Specific Action |

Control Ambient Temperature | Maintain optimal working temperature range | Use air conditioning or temperature control systems to keep the ambient temperature between 18°C-22°C. |

Optimize Ventilation | Enhance airflow and reduce temperature fluctuations | Use industrial fans, exhaust systems, etc., to ensure air circulation and prevent heat accumulation. |

Regular Monitoring of Temperature and Humidity | Prevent temperature fluctuations affecting machine operation | Install temperature and humidity sensors to monitor environmental conditions in real-time and automatically adjust air conditioning or ventilation systems. |

Machine Tool Operation and Maintenance

Work in Shifts: Avoid continuous high-load operation.

In high-temperature conditions, running machine tools at full load for extended periods accelerates wear and tear. It is recommended to operate the machine tool in shifts, allowing it to rest after 2-3 hours of operation to prevent overheating of critical components.Lubrication and Cooling Maintenance:

Regularly check the condition of lubricants and cooling liquids to ensure the lubrication and cooling systems are working properly.Use high-temperature-resistant lubricants, clean the lubrication system regularly, and ensure lubrication effectiveness.

During high-temperature seasons, oil mist lubrication systems or enhanced coolant flow should be used to optimize cooling.

Enhance Electronic System Cooling:

Regularly check the cooling performance of electronic systems to ensure that the CNC system, servos, and other components are not overheating.Additional cooling devices, such as air cooling or liquid cooling systems, can be installed to help keep the electronic systems within an optimal temperature range.

4. Machine Tool Maintenance During Shutdown: How to Store and Maintain Under High Temperature?

Even when not in operation, maintaining machine tools in high-temperature environments is crucial. Below are key maintenance tips to ensure the machine tool remains in good condition during downtime:

Thorough Cleaning Before Shutdown:

High temperatures can cause dust, oil, and other substances to accumulate on machine surfaces, affecting heat dissipation and lubrication. Before shutting down, clean the worktable, guide rails, spindle, and other critical components to remove dust and oil.Maintain Dry and Temperature-Controlled Storage Conditions:

If a machine tool needs to be out of operation for a long time, store it in a controlled environment with appropriate temperature and humidity. Excessive temperature and humidity can lead to corrosion and equipment aging.Try to keep the warehouse temperature between 20°C-25°C to avoid prolonged exposure to extreme conditions.

Regularly Check the Machine’s Status:

Even when not in use, regularly check the lubrication system, cooling system, electrical components, and other parts to ensure they remain in good working condition.For precision parts such as sensors and spindles, apply protective oils to prevent moisture or oxidation-related damage.

5. Why Choose Minnuo Machine Tools?

In high-temperature environments, machine performance depends not only on operational management but also on the machine tool’s design and configuration. Minnuo machine tools have successfully addressed the common performance issues that arise under high-temperature conditions, ensuring that you can maintain excellent processing precision and production efficiency in extreme environments.

High-Temperature Structural Design and Components: Using high-strength cast iron and low-expansion alloy steel, Minnuo machine tools ensure that critical components remain stable and do not deform under high temperatures. The cast iron base and high-temperature alloy materials are designed to withstand high-temperature pressures, maintaining long-term stable operation and ensuring processing precision is unaffected.

Liquid Cooling System: The high-efficiency liquid cooling system circulates coolant between key components such as the spindle, guide rails, and motors, ensuring that each part’s temperature remains within the optimal working range. The system automatically adjusts coolant flow based on machine load to prevent overheating and improve operational stability and equipment longevity.

Intelligent Overheating Protection: The electronic system is equipped with built-in overheating protection. Temperature sensors monitor key components in real-time. When temperatures exceed safe limits, the system automatically adjusts the workload or activates backup cooling to prevent damage to electronic components, ensuring stable operation in high-temperature environments.

iNC-Cloud Intelligent Platform: The iNC-Cloud intelligent platform connects each machine tool to a centralized service hub. The system automatically generates a service ticket and pushes it to the engineer, while simultaneously notifying the user by SMS. Engineers can remotely view the machine’s status, quickly assess faults, and provide guidance to resolve issues, reducing downtime and ensuring continuous production.

Conclusion:

Through meticulous management and detailed operations, machine tool performance can not only be maintained but also extended over time. High temperatures are not insurmountable; the key lies in how we respond and manage them.

If you are still struggling with the impacts of high temperatures, contact Minnuo. We will provide you with a comprehensive, efficient solution to address the challenges effectively!

Email

Email sales1: +86 13295238763

sales1: +86 13295238763