How to Prevent Spiral Marks in Centerless Grinding?

Have you ever encountered spiral patterns suddenly appearing on the surface of a workpiece during centerless grinding? These defects not only affect the product's appearance but can also reduce machining accuracy and even cause potential quality issues.

To prevent spiral marks during centerless grinding, the key lies in ensuring wheel and regulating wheel alignment, optimizing grinding parameters, and regularly dressing the grinding wheel. In addition, proper workpiece support, consistent feed rate, and the use of appropriate coolant can effectively reduce the occurrence of spiral marks.

Today, let’s take a deep dive into the causes of spiral marks, and provide practical solutions to help you eliminate the issue at its root.

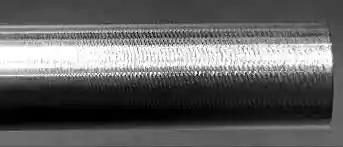

1. What Do Spiral Marks Look Like?

Spiral marks usually appear as circular or spiral lines around the surface of the workpiece. As the workpiece rotates, these lines form continuous spiral patterns. They may be uniformly distributed or irregular due to instability in the machining process.

How to tell if it’s a spiral mark?

Visual inspection: Spiral marks generally extend along the length of the workpiece in a spiraling fashion. You can visually observe them or use a magnifier. If you notice continuous spiral traces, they are likely spiral marks.

Touch test: Spiral marks affect surface smoothness. If you feel noticeable undulations or friction when touching the surface, it’s likely caused by spiral marks.

Differences between spiral marks and other defects:

Broaching marks: Typically straight lines, different from the spiral shape of spiral marks.

Scratches: Usually irregular and raised, not arranged in a spiral or circular pattern.

2. Causes of Spiral Marks

To effectively address spiral marks, we must first understand what causes them. The issue can stem from several main aspects:

Machine-related issues:

Misalignment of grinding and regulating wheels: If the wheels are not kept parallel or the workpiece is not properly aligned, spiral grinding patterns can easily occur.

Inadequate workpiece support: If the workpiece is not securely supported, slight movement or displacement during grinding can lead to spiral marks.

Grinding wheel issues:

Improper wheel dressing: If the grinding wheel surface is not evenly dressed, it will make irregular contact during grinding, causing spiral marks.

Wheel wear: Over time, the wheel may wear unevenly. An uneven wheel surface directly affects the workpiece, resulting in spiral marks.

Process parameter issues:

Mismatch in wheel speed, feed rate, and pressure: Excessive speed or inappropriate feed rate can cause irregular surface markings, resulting in spiral patterns.

Insufficient or unsuitable coolant: Coolant plays a vital role. If it's inadequate or incompatible with the grinding conditions, it can cause overheating or uneven grinding forces, leading to spiral marks.

Material-related factors:

The properties of the workpiece material can influence the grinding outcome. Differences in hardness, toughness, and machinability can all affect the likelihood of spiral marks—especially if the material is too hard or too soft.

3. Solutions to Prevent Spiral Marks

Having identified the root causes of spiral marks, we can now look at practical ways to prevent them:

Proper machine setup and maintenance:

Ensure alignment of grinding and regulating wheels: Regularly check and adjust their alignment to maintain required parallelism.

Stable workpiece support: Ensure the workpiece is properly supported during processing to avoid movement that could affect surface quality.

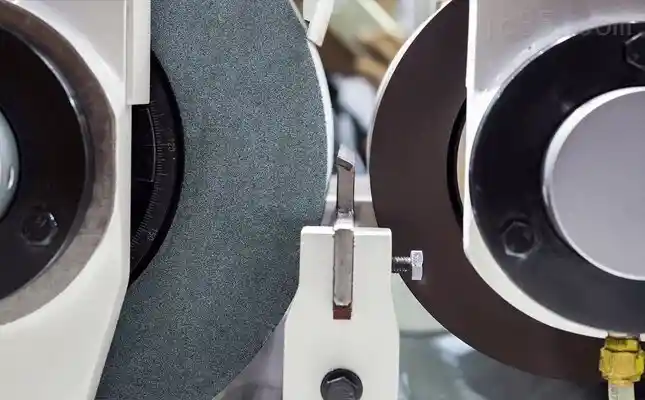

Grinding wheel dressing and selection:

Choose the right grinding wheel: Select a wheel type and grit size suitable for the material, hardness, and desired surface quality.

Dress the wheel regularly: Maintain a consistent wheel profile by checking wear regularly to prevent spiral marks from uneven surfaces.

Optimize grinding parameters:

Adjust wheel speed and feed rate: Fine-tune speed, feed, and pressure based on the workpiece characteristics and grinding requirements to avoid unstable grinding.

Use appropriate coolant: Ensure the coolant flow rate and pressure match the processing conditions for effective cooling and consistent grinding force.

Workpiece handling and support:

High-quality supports and fixtures: Use precision supports and fixtures to ensure even contact with the grinding wheel and stable rotation without deviation.

Maintain consistent feed rate: Avoid fluctuations in feed rate that can cause uneven surface load and irregular marks.

4. How to Fix Existing Spiral Marks

Even with preventive measures, spiral marks may occasionally occur. Here’s how to fix them:

Dress the grinding wheel: Redress the wheel profile to eliminate the root cause of uneven grinding.

Adjust grinding parameters: Optimize wheel speed, feed rate, and pressure based on the severity of the marks to improve surface smoothness.

Surface polishing: Use fine grinding or polishing techniques to remove irregularities and restore surface smoothness.

5. Other Common Defects Besides Spiral Marks

Apart from spiral marks, centerless grinding may cause other surface defects. Knowing their causes and solutions can help you comprehensively improve grinding quality:

Common grinding defects and solutions:

Broaching marks: Often caused by uneven cutting or fluctuating feed speed. Solution: Regular wheel dressing and maintaining stable feed speed.

Scratches: May result from surface contaminants or unsuitable wheel material. Solution: Clean the workpiece thoroughly and select a compatible grinding wheel.

Burn marks: Caused by excessive grinding heat, leading to discoloration or surface damage. Solution: Improve coolant delivery and reduce grinding speed as needed.

Dimensional deviation: Due to poor precision control. Solution: Calibrate machine alignment and optimize process parameters.

6. Steps to Troubleshoot Spiral Marks

If spiral marks are already present during processing, systematic troubleshooting is key. Follow these steps:

Check alignment of grinding and regulating wheels: Ensure they are parallel and meet alignment standards.

Inspect grinding parameters: Review settings for speed, feed rate, and pressure to identify any mismatches.

Examine workpiece support: Confirm that fixtures are stable and that the workpiece is not shifting during grinding.

7. Conclusion

Preventing spiral marks requires a multi-dimensional approach: proper machine settings, optimized wheel condition, stable workpiece support, and careful attention to coolant selection and delivery.

If you want to learn more about centerless grinding technology or are facing other grinding challenges, feel free to contact us at Minnuo. We provide professional technical support and customized solutions to help you improve machining efficiency and reduce defects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763