Tariff Shifts Spark New Opportunity: Can China’s Machine Tool Makers Power North America’s EV Factory Boom?

Trump-era tariffs are shaking up the traditional auto industry, driving up vehicle costs and exposing supply chain vulnerabilities. In contrast, emerging EV makers like Lucid and VinFast currently face less pressure — many have already established plants in North America and begun building localized supply chains.

However, cracks are emerging: while local manufacturing is underway, the supporting supply chain remains underdeveloped. As these new brands scale from low-volume trials to mass production, shortfalls in parts machining, equipment delivery, and process capability quickly come to light.

As automakers accelerate North American localization, cost-effective, advanced Chinese machine tools could become a key enabler — but challenges remain.

I. EV Manufacturing Undergoes a Tariff-Driven Shift

The U.S. has dramatically increased tariffs (potentially over 60%) on Chinese EVs and critical components, prompting a massive shake-up. Global leaders like Tesla, Volkswagen, BYD, and CATL are investing billions in new plants across Mexico, the U.S., and Canada. This isn’t just final assembly — it’s about rebuilding entire regional supply chains from the ground up.

Result: soaring demand for advanced manufacturing equipment, especially high-precision, high-efficiency CNC machines.

II. How Chinese Machine Tools Fit the New Landscape

China’s machine tool industry has moved far beyond its low-cost origins. In multiple core EV processes, it now delivers globally competitive solutions. For cost-sensitive manufacturers setting up new North American plants, Chinese machines present a strong value proposition:

Battery Manufacturing

Needs: High-volume, high-precision machining of aluminum battery housings, cell caps, cooling plates. Requires high-speed, high-stability Vertical Machining Centers (VMCs) and 5-axis machines to handle complex geometries.

(aluminum battery housings)

Chinese Players & Tech:

Haitec (Haitian Precision): Known for the rigidity and thermal stability of its HA series VMCs, ideal for long-duration battery part production.

Minnuo Machine Tools: Offers high-speed VMCs optimized for aluminum machining.

Value Proposition:

Cost Structure: 30–40% lower acquisition cost due to China’s complete local supply chain (e.g., Huazhong CNC systems, domestic spindles and ballscrews) and scaled manufacturing.

Technical Fit: Purpose-built for high-volume, standardized battery pack production, offering ±0.02mm stability without overengineering for aerospace-level precision.

Quick Delivery: Companies like Haitec and SMTCL have delivered turnkey battery housing lines for CATL and BYD in China, aligned with gigafactory-scale ramp-up needs.

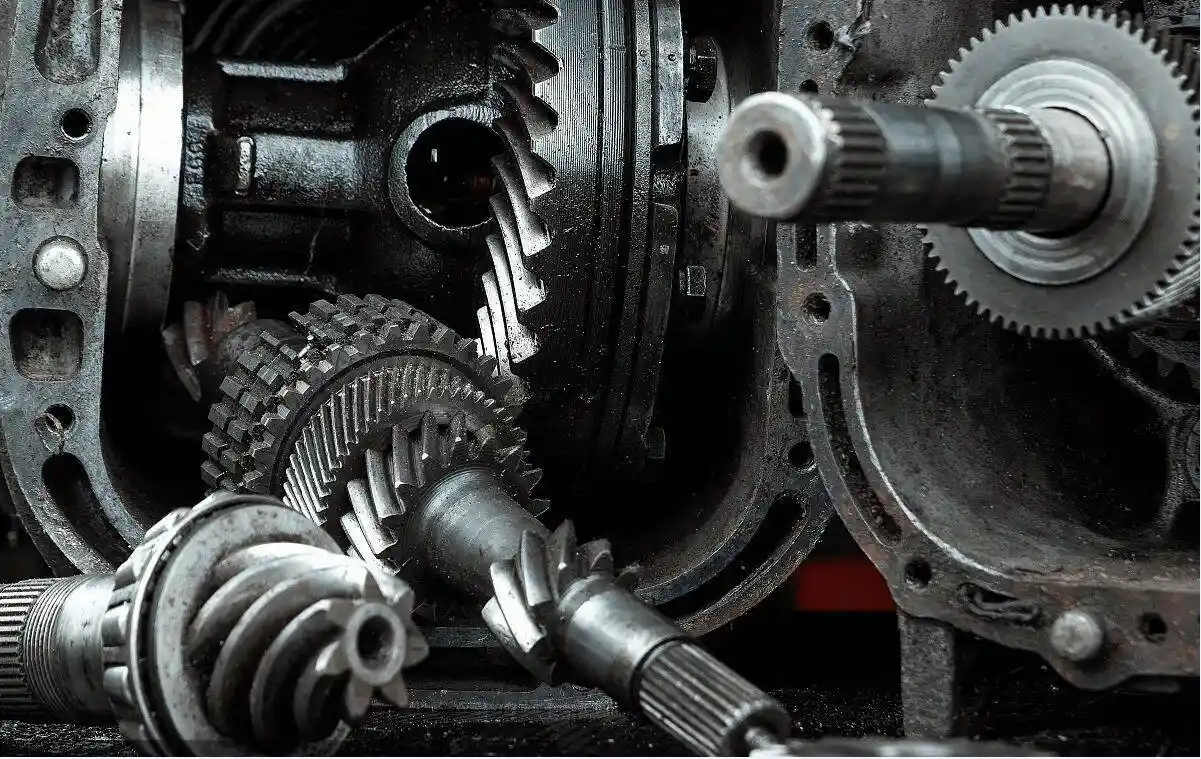

E-Drive Systems (Motors & Gearboxes)

Needs: Ultra-precise machining of motor shafts, housings, stators/rotors, and gearbox parts. Relies on multitasking turn-mill centers and precision grinders.

Chinese Players & Tech:

Qinchuan Machine Tool (QCMT): Leader in gear hobbing and shaping machines.

GENOS (Beiyi-Okuma): High-precision CNC lathes and turn-mill centers gaining traction in the EV drivetrain space.

Value Proposition:

Scalable Specialization: QCMT machines achieve DIN 6 or better gear quality at 25–35% lower cost than German/Japanese brands, enabled by decades of mass-production expertise.

Integrated Fixturing: GENOS centers feature built-in fixtures for common EV parts like motor end caps, reducing setup time and auxiliary costs vs. modular Western systems.

TCO Advantage: Lower service and spare part costs backed by China’s vast component ecosystem translates into significant long-term savings — ideal for Tier 1 mass producers.

Body-in-White & Megacasting

Needs: Machining of massive one-piece aluminum castings, body panels, and chassis parts. Requires gantry mills, large 5-axis machines, and automated machining lines.

Chinese Players & Tech:

DMTG (Dalian Machine Tool): Supplies heavy-duty gantry mills and 5-axis bridge mills.

Haitian Precision: Partners with leading die-casters like LK to provide integrated post-casting machining solutions.

Value Proposition:

Rigidity-to-Price Ratio: DMTG machines deliver comparable stiffness and dynamics to premium brands but are 25–30% more affordable thanks to China’s casting and forging cost advantages.

Throughput Focus: Machines prioritize high material removal rates (MRR) for secondary ops like datum milling and hole drilling — ideal for EV factories where speed is key.

III. Capturing the Moment: The Localization Wave

The scale of new factory investment has opened a clear market window:

New Line Demand: Mexico, U.S., and Canada greenfield factories need full machining lines, not just individual machines.

Cost Sensitivity: With tariffs squeezing margins, affordable machines that meet performance thresholds are a practical solution.

Supply Chain Migration: As Chinese Tier 1/2 suppliers establish facilities in Mexico, they prefer familiar Chinese machine tool brands.

IV. Beyond Price: Chinese Machine Tools Face Three Key Challenges

Chinese brands must navigate more than just technical hurdles — credibility, localization, and compliance are essential for winning trust in mature markets.

1. Quality Perception & Service Trust

Past doubts over Chinese machine tool quality persist among overseas buyers. However, this is changing. Leaders like Haitec and QCMT have validated their performance via third-party testing, exports, and stable operation in production environments.

Minnuo and others are enhancing local service networks:

Establishing spare part & service centers (e.g., Monterrey, Mexico)

Training local engineers

Providing 24/7 multilingual technical support

Partnering with experienced North American distributors

2. Geopolitical & Compliance Risk

Participation in sensitive sectors (like batteries) means exposure to CFIUS and supply chain scrutiny. Chinese companies are responding with proactive compliance:

Swapping restricted components for neutral alternatives

Offering transparent data safeguards

Supporting local final assembly and commissioning by North American integrators

3. Competing with Legacy Giants

Top players like DMG MORI, Makino, and Okuma have entrenched customer bases. But China’s opportunity lies in high-volume, moderately complex components — like battery trays, aluminum housings, and megacastings — where price/performance balance is key.

Chinese machines offer faster delivery, better efficiency, and smart automation options — making them a rational choice for customers balancing performance and budget.

V. Conclusion: Seizing the EV Moment with Smart Strategy

The North American EV factory boom presents a genuine opportunity for China’s advanced machine tools. Technology maturity, price competitiveness, and alignment with localized production goals create a strong market entry point.

But true competitiveness lies beyond hardware — in globalized service delivery and agility in navigating policy headwinds. Firms like Haitec, QCMT, and Minnuo — already expanding their international support networks — are well-positioned to lead.

For OEMs and Tier 1 suppliers, choosing Chinese machines with robust local support could be a pragmatic strategy to control capital costs amid tariff pressure.

The next wave of North American EV expansion may not wear a “Made in China” badge — but behind the scenes, it may well be powered by Chinese-built machine tools driving the production line.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763