The "Measurement Master" Behind the Geneva Gold Award: What Is the Key Function of the Grating Scale in CNC Machine Tools?

In 2025, GREE’s independently developed high-speed double five-axis gantry machining center (GA-FMB3020D) won the gold medal at the 50th Geneva International Exhibition of Inventions, surpassing European and American counterparts with a machining precision of 0.001mm. It successfully entered the supply chains of global giants like Tesla and BMW, sparking widespread attention in the global machine tool industry. Concurrent data shows that the global ultra-precision machine tool market is expected to exceed $18 billion, with increasing demand for high-precision machining in industries like aerospace and new energy vehicles. At the heart of this precision lies a critical component—the grating scale.

The core function of the grating scale in CNC machine tools is to continuously detect the movement position of the coordinate axes and provide real-time feedback, dynamically compensating for mechanical transmission errors, monitoring the motion state, and assisting multi-axis synchronization control. Ultimately, it ensures the positioning accuracy, repeatability, and stability of the machine tool, making it the cornerstone of achieving high-precision machining.

Next, we will gradually break down the core functions, working principles, installation adaptations, and common applications of the grating scale to help you comprehensively understand the real value of this key component.

1. Core Functions of the Grating Scale in CNC Machine Tools

The grating scale is not only a position detection device but also a key sensor component that influences the overall accuracy, stability, and efficiency of the machining system.

Real-Time Position Detection and Feedback:

Precisely captures the real-time movement position of the machine tool's coordinate axes, whether for linear or rotational motion, with millisecond-level data acquisition.

Transmits the acquired position data in real-time to the CNC system, forming a closed-loop control circuit to ensure the system has an accurate understanding of the movement state, preventing position error accumulation.

Assurance and Compensation of Machining Precision:

Offsets errors such as backlash and friction errors that occur in the machine tool's mechanical transmission, significantly improving positioning and repeatability accuracy.

Monitors position deviations in real-time during operation, dynamically adjusting parameters through the CNC system to compensate for errors, ensuring consistent precision across batch processing of parts.

Motion State Monitoring and Control:

Synchronously monitors the movement speed, acceleration, and travel range of the coordinate axes, providing the system with comprehensive motion state data.

Cooperates with the CNC system to implement over-travel protection, issuing a signal to stop operation if the movement exceeds the set range, ensuring uniform processing speeds and preventing speed fluctuations from affecting processing quality.

Auxiliary Synchronization Control:

In multi-axis linked machining scenarios, calibrates the positional synchronization of the coordinate axes to ensure the movement trajectory aligns with the preset program.

Provides precise trajectory control support for complex curves and irregular parts machining, avoiding machining failures caused by multi-axis coordination deviations.

2. Working Principles of the Grating Scale to Achieve Core Functions

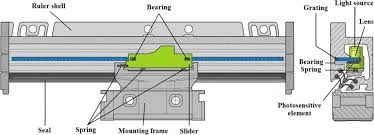

To understand how the grating scale "achieves" its functions, it's important to grasp its basic structure and signal principles.

Component | Function Description |

Grating Scale | Fixed on the measuring axis, providing precise grating reference |

Indicator Grating | Installed in the readhead, forms interference fringes with the grating scale |

Photoelectric Conversion Unit | Reads the Moiré fringe variations and converts them into electrical signals |

Signal Processing Module | Converts analog signals into digital signals and feeds them back to the control system |

When light is projected onto both the grating scale and the indicator grating, their slight relative displacement forms Moiré fringes. The light-electric component reads these fringes, generating sinusoidal signals that represent the displacement, which are processed by subdivision circuits and converted into standard feedback signals to the control system, completing precise positioning and control logic in a closed-loop.

3. Types and Functional Adaptability of Grating Scales

Different types of grating scales differ in their functional emphasis and applicable scenarios. Choosing the right type is key to ensuring machine tool performance.

By Measurement Method:

Type | Functional Difference | Applicable Scenarios |

Only outputs relative displacement signals, requires an origin switch to determine initial position, lower cost, fast response | Mid-to-low-end CNC machines, batch processing of standard parts | |

Absolute Grating Scale | Outputs absolute position signals directly, retains position information even after power loss, higher precision | High-end precision machine tools, complex part machining, continuous production scenarios |

By Installation Position:

Type | Functional Focus | Applicable Scenarios |

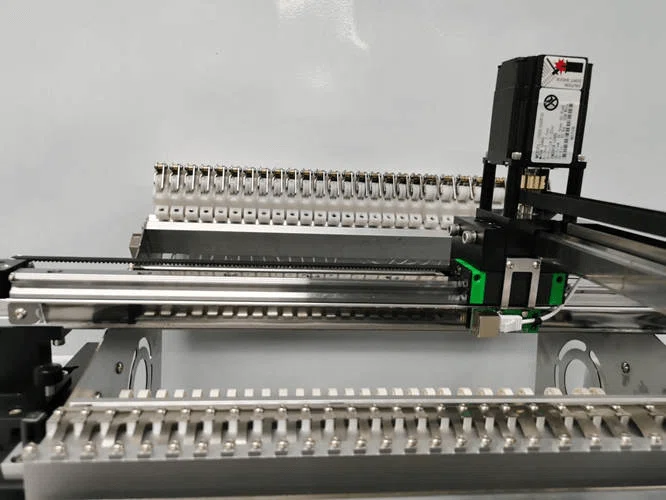

Linear Grating Scale | Focuses on linear displacement detection, long travel measurement, high positioning accuracy | Gantry mills, vertical machining centers, and other devices focused on linear motion |

Rotary Grating Scale | Suitable for rotational motion detection, compact size, adapts to high-speed rotation scenarios | CNC lathes, milling machine spindles, and other rotating parts position detection |

In practice, the selection of a grating scale type must take into account the machine tool's precision requirements, motion type, and production scenario to fully harness its functional value.

4. Key Influencing Factors in the Performance of Grating Scales

Even with high precision, the grating scale needs good environmental and installation conditions to perform effectively.

Installation Accuracy:

When installing, ensure that the grating scale and indicator grating are parallel and perpendicular to each other, with a gap control within the 0.1-0.2mm range, otherwise, signal distortion may occur.

It is recommended to use professional calibration tools for installation and debugging, followed by multiple positioning tests to ensure data stability.

Environmental Adaptation:

Temperature changes may cause expansion or contraction of the grating scale's lines. It is recommended to maintain the working environment temperature at 20 ± 2°C, avoiding direct sunlight or proximity to heat sources.

Dust and oil can wear down the lines and interfere with the signals. Protective devices should be used for the grating scale, and the surrounding area should be cleaned regularly. In humid environments, dehumidification equipment should be added.

Maintenance:

Regularly check the grating scale's connection lines to avoid loose or aging lines, which may affect signal transmission.

Clean the surface of the grating scale monthly using specialized cleaning agents to avoid scratching the lines, and perform precision calibration every quarter to ensure stable performance.

5. Comparison of Grating Scales with Other Detection Devices

Detection Device | Accuracy | Anti-Interference Capability | Lifespan | Applicable Scenarios |

Grating Scale | High (up to ±0.001mm) | Medium (affected by dust and oil) | Long (5-8 years with proper maintenance) | High-precision machine tools, linear displacement detection |

Medium (normal accuracy ±0.01mm) | High (sealed structure, strong anti-interference) | Medium (wears faster under high-speed rotation) | Spindle speed detection, rotating parts positioning | |

Magnetic Grating Scale | Medium (accuracy ±0.005mm) | High (strong resistance to dust and moisture) | Medium (magnetic field changes may affect precision) | Displacement detection in harsh environments |

From a high-precision machining perspective, grating scales have a clear advantage in accuracy, making them the preferred detection device for high-end CNC machine tools, especially in fields requiring stringent precision such as aerospace and precision molds, where the function of the grating scale is irreplaceable.

6. Typical Application Scenarios of Grating Scales

Precision Part Machining:

When machining small holes or thin-walled parts, the grating scale ensures dimension control within ±0.001mm, avoiding deformation and error accumulation.

Complex Surface Machining:

For mold surfaces or aerospace irregular parts requiring five-axis or multi-axis coordinated trajectory control, the grating scale ensures inter-axis synchronization, maintaining contour precision.

Batch Production Scenarios:

In batch processing of parts, repeatability directly affects product consistency. The grating scale feedback system minimizes error differences between batches.

7. Upgrades and Future Trends of Grating Scale Functions

Higher Precision:

Grating scales with nano-level resolution are now available to meet the micro-manufacturing needs of semiconductor and optical components.

Grating scales with nano-level resolution are now available to meet the micro-manufacturing needs of semiconductor and optical components.

Intelligent Development:

Intelligent grating scales, integrating self-calibration, health diagnostics, and remote monitoring, are gradually replacing traditional models, enhancing system automation levels.

Multi-Dimensional Detection Expansion:

Future grating scales will further integrate Z-axis precision, angle measurement, and temperature compensation, providing comprehensive support for high-end equipment manufacturing.

8. Common Functional Faults and Troubleshooting Suggestions

Fault Performance | Possible Cause | Troubleshooting Suggestions |

Inaccurate Position Detection | Grating surface contamination, installation deviation | Clean the surface, recalibrate |

No Feedback Signal | Loose signal lines, damaged photoelectric components | Check connections and component status |

Precision Fluctuation | Large temperature differences, loose readhead | Install temperature control devices, tighten components |

In on-site troubleshooting, it is recommended to first rule out simple physical factors and then progressively explore electronic signal and system interaction aspects.

9. Grating Scale Brands and Precision Levels

The grating scales used in our CNC machine tools are all sourced from the world’s top two brands—Heidenhain and Renishaw. These two companies together dominate over 70% of the global grating scale market, widely used in high-end equipment from brands like Siemens, Makino, and Haas.

Brand | Positioning Accuracy | Repeatability Accuracy | Certification Standards |

Heidenhain | ±0.001mm | Better than ±0.002mm | ISO 230-2:2012 |

Renishaw | ±0.0015mm | ±0.002mm | ISO 230-2:2012 |

These configurations fully meet the precision and consistency requirements of industries such as automotive molds and aerospace structural parts.

10. Summary and Key Takeaways

The grating scale is not just a detection device but is critical in ensuring machine tool positioning accuracy, repeatability, and dynamic control.

Although small, the grating scale is determining the "precision limits" for the future of manufacturing. For more information, feel free to contact us at Minnuo!

11. FAQ:

Q1: Is there a direct relationship between the accuracy level of the grating scale and its functionality?

Yes. The higher the accuracy level, the better the resolution and error compensation capability, making it suitable for equipment requiring micron-level precision control.

Q2: What problems might a CNC machine face without a grating scale?

It cannot achieve closed-loop control, making real-time error compensation impossible. This often leads to cumulative errors, especially in multi-axis or long-stroke machining operations.

Q3: Can the performance of a grating scale be enhanced through software optimization?

Partially. Control algorithm improvements such as predictive compensation and signal filtering can enhance stability, but the grating scale must have a stable, high-precision hardware foundation.

Q4: How should one select the proper grating scale configuration based on machining standards?

Refer to industry standards (e.g., ISO 230 series), in-house precision requirements, and part tolerance limits to select a model with the appropriate resolution and repeatability accuracy.

Q5: What are the main differences between incremental and absolute grating scales?

Incremental scales require a reference point reset to determine the origin; they are low-cost and fast. Absolute scales, however, directly output absolute position data and retain it even after power loss, ideal for high-precision, continuous production environments.

Q6: What key factors should be considered during grating scale installation?

Ensure parallelism and perpendicularity between the scale and readhead, keep the gap within 0.1–0.2mm, use professional calibration tools, and perform multiple post-installation accuracy tests.

Q7: How significantly do environmental factors affect grating scale performance?

Very significantly. Temperature fluctuations cause thermal expansion errors, while dust and oil can disrupt signals. Maintain 20 ± 2°C ambient temperature, install protective covers, and use dehumidification in humid environments.

Q8: What are the advantages of grating scales compared to encoders or magnetic scales?

Grating scales excel in accuracy (up to ±0.001mm), ideal for high-end CNC machines and linear displacement detection. Encoders and magnetic scales, however, offer better interference resistance and environmental adaptability.

Q9: How does a grating scale work?

A grating scale consists of a main scale, an index grating, a photoelectric conversion unit, and a signal processing module. When light passes through the scale and index gratings, slight displacements create Moiré fringes. These are read by the photoelectric unit and converted into sine wave signals, then digitized and sent to the CNC system, enabling precise closed-loop position control.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763