What Are the Types of Milling?

In the context of the intensifying global semiconductor race, ASML’s latest financial report reveals that its extreme ultraviolet (EUV) lithography machine production surged 67% in Q2 2023, with its core vacuum chamber processing relying heavily on five-axis precision milling technology. At the same time, Tesla's Berlin Gigafactory faced a bottleneck in Model Y production, as the 4680 battery cell casing processing efficiency could not meet demand, halting the weekly production at 5,000 units. This further underscores the critical role that CNC milling technology plays in modern manufacturing.

Types of milling are mainly classified into end milling, face milling, and side milling, each suited for different processing needs. For example, end milling is excellent for three-dimensional contour machining, face milling is the most efficient method for large flat surfaces, while side milling is the ideal solution for deep groove processing.

Let’s now explore how optimizing milling processes can improve machining accuracy and efficiency.

I. Core CNC Milling Types: 3 Basic Classification Systems

1.Milling Methods Based on Tool Path

A. End Milling:

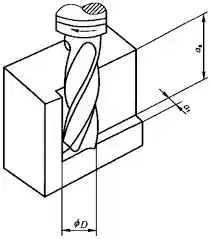

A Versatile Contour Machining Solution End milling uses a vertical-axis tool to cut through both the end face and side of the tool, making it ideal for processing complex geometric contours. The tool structure allows for free movement along the X/Y/Z axes, which is particularly useful for cavity slotting and 3D surface engraving.

Technical Advantage: Vertical tool axis enables 3D profiling of mold cavities.

Operating Parameters:

Aluminum: Recommended feed rate of 0.1-0.3mm/tooth.

Stainless Steel: Suitable for 4-6 flutes.

Industrial Case: Using a 12mm carbide end mill for gearbox slot machining.

B. Face Milling: Efficient Flat Surface Processing

Face milling utilizes a disc-shaped tool parallel to the workpiece surface for large-scale material removal. With radially arranged blades, it achieves high-speed cutting with minimal vibration, setting the benchmark for flat surface machining efficiency.

Productivity Benchmark: Cast iron material removal rate of 500 cm³/min, 40% higher than end milling.

Tool Innovation: 45° lead angle tools reduce vibration for thin-walled aerospace components.

Keyword Integration: Use of indexable face milling systems optimizes large-area flat surface processing.

C. Side Milling: Expert Solution for Deep Groove Processing

Side milling employs the side edge of the tool for depth cutting, removing material in axial layers. It’s the preferred method for deep grooves, T-shaped slots, and similar structures, particularly for features with high depth-to-width ratios.

Machining Depth: Capable of 8x tool diameter deep groove machining in titanium alloy aerospace brackets.

Parameter Tips: Use spiral tools to suppress vibrations during deep cavity machining.

Key Technical Comparison Table

Parameters | End Milling | Face Milling | Side Milling |

Cutting Force Direction | Axial + Radial | Radial Dominant | Radial Dominant |

Typical Ra Value | 0.8-3.2μm | 0.4-1.6μm | 1.6-6.3μm |

Power Consumption | 3-15kW | 10-50kW | 5-25kW |

Applicable Scene | 3D Contours | Large Flat Surfaces | Deep Grooves/Side Walls |

2.Machine Tool Configuration Strategy Comparison

Milling Type | Best Suitable Workpiece | Tolerance Range | Max Spindle Speed |

Vertical Milling | Complex 3D Molds | ±0.005mm | 12,000 RPM |

Horizontal Milling | Heavy Castings | ±0.02mm | 8,000 RPM |

Five-Axis Milling | Turbine Blades | ±0.01mm | 15,000 RPM |

Technical Insight: Horizontal milling excels in batch production of engine blocks, achieving 95% spindle utilization with automated pallet systems.

3.Precision Grading System

A. Rough Milling: Efficient Material Removal

Steel Part Processing: 5mm cutting depth with variable feed strategy.

Cost Optimization: Combined toolpaths for roughing and semi-finishing.

B. Precision Milling: Perfect Surface Finish

Achievable Quality: Diamond-coated tools achieve Ra0.2μm mirror finish.

Process Innovation: Nano-grain carbide tools used in medical implant precision machining.

Technical Breakthrough: Minnuo uses multi-axis compensation algorithms and nano-coated tools to achieve Ra 0.2μm surface finish on P20 mold steel, improving precision milling efficiency by 40%.

II. Industry-Specific Milling Solutions

Automotive Metal Milling Solutions:

Cylinder Block Face Milling: 315mm diameter PCD blade face mill.

Gear Profile Milling for Transmissions: High-efficiency processing of 58HRC hardened steel.

Aerospace High-Speed Machining:

Turbine Blade Five-Axis Milling: Titanium alloy machining at 800 m/min cutting speed.

Composite Material Edge Finishing: Diamond-coated tools for carbon fiber board processing.

Medical Industry Milling Solutions:

Micro Milling: 0.05mm tools for cochlear implant channel machining.

Cobalt-Chromium Alloy Polishing: Non-contact laser-assisted fine finishing.

III. Factors to Consider When Choosing Milling Processes

Material-Specific Tools:

Aluminum: High-spiral ZrN-coated end mills.

Inconel Alloys: Ceramic-enhanced variable pitch tools.

Production Scale Economics:

Prototyping: Vertical machining centers with quick-change fixtures.

Mass Production: Horizontal machining centers with 120-tool automatic tool changers.

Surface Finish Requirements:

ISO N6: Requires vibration-damping spindle technology.

ISO N8: Standard CNC milling capability.

Cost-Efficiency Balance:

Tool Life Optimization: Adaptive feed control reduces costs by 30%.

Advanced Process Integration: AI vibration detection boosts thin-wall part machining efficiency by 20%.

Hybrid Manufacturing Technologies: Combining additive deposition with precision milling.

IV. Intelligent Milling Systems

Our Minnuo Industry 4.0 milling solutions offer:

Real-time Process Monitoring: Vibration sensors prevent tool breakage.

Multi-Material Expertise: Solutions for everything from aluminum alloys to carbon fiber composites.

Case Study Result: Five-axis optimization accelerates turbine blade processing by 40%.

V . Technical FAQ: Milling Process Optimization Guide

Q1: When should face milling be chosen over end milling for stainless steel processing?

A: Use face milling for wide flat surfaces (>60mm), and end milling for shallow slots (<15mm depth).

Q2: What is the recommended spindle speed range for cast iron in horizontal milling?

A: For coated carbide tools, the recommended range is 600-800 RPM with 10-12mm cutting depth.

Q3: How to perform precision milling for hardened molds?

A: Use CBN tools with cycloidal tool paths and set a 0.05mm step distance.

Conclusion:

From nano-level lithography machines to gigawatt-scale energy storage devices, global high-end manufacturing breakthroughs all begin with milling process innovations. Minnuo’s intelligent system achieves ±0.006mm precision through five-axis dynamic compensation, with multi-material solutions covering over 200 special alloys and composite materials.

If you have any questions about milling, take action now and visit our website at any time.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763