How to Choose the Right Machine Tools for Post-Conflict Reconstruction in the Middle East

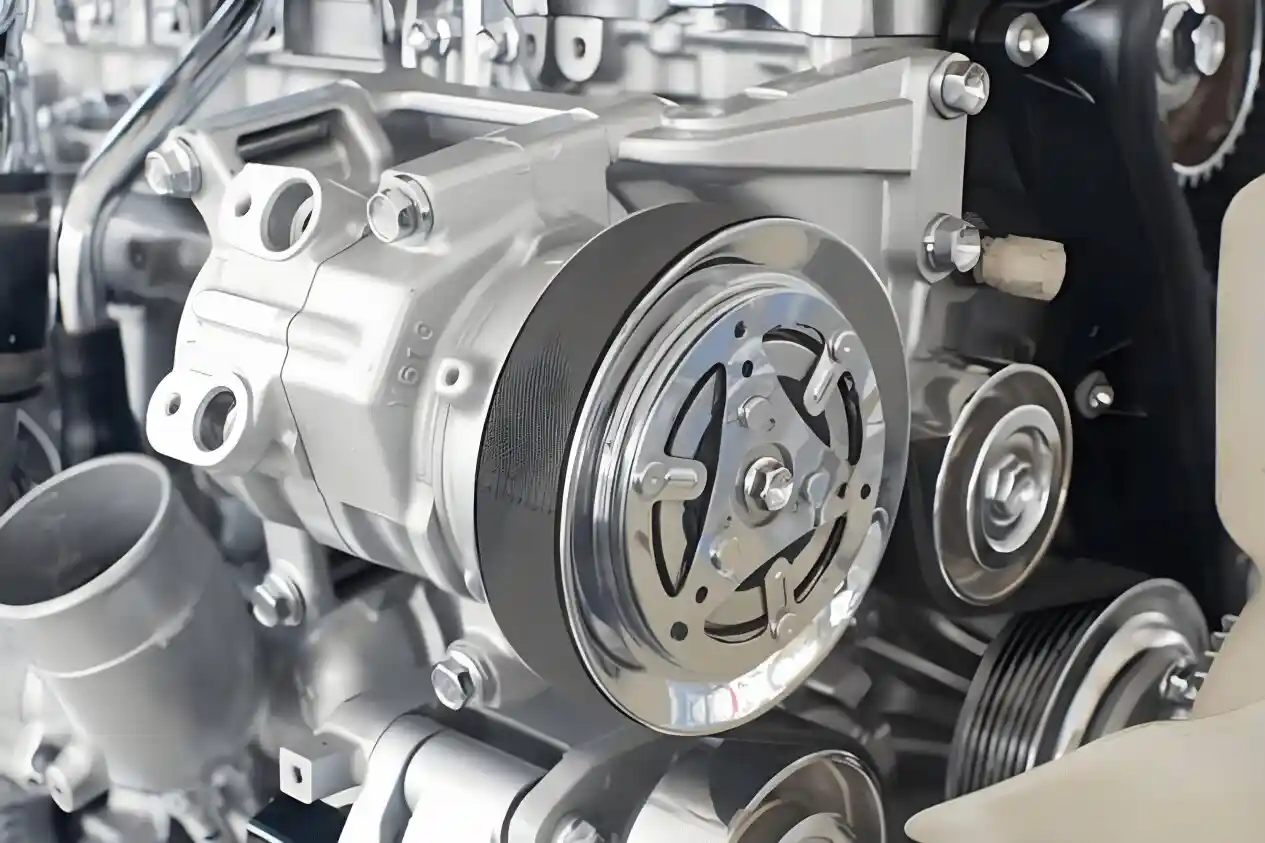

As industry veterans who have been deeply engaged in the machine tool sector for many years, we’ve witnessed the strategic importance of the Middle East in the global industrial landscape, thanks to its geopolitical position and energy resources. The recent conflict between Iran and Israel has severely damaged industrial facilities in the region, ushering in a massive wave of reconstruction. As countries plan their post-war recovery, it has become clear that machine tools are not merely instruments for rebuilding—they are the very engines driving industrial modernization.

In the reconstruction of energy, construction, transportation, and industrial manufacturing sectors, the Middle East urgently needs traditional machine tools such as lathes, milling machines, and drilling machines to restore basic production capabilities. At the same time, demand for high-precision equipment—such as CNC lathes and machining centers—is also surging, especially in key sectors like oil and gas, aerospace, and advanced manufacturing. Different industries require different types of machine tools to meet the challenges of reconstruction, including heavy-duty lathes, CNC machines, cutting machines, and welding equipment.

As post-conflict rebuilding progresses, the demand for machine tools continues to grow. We are fully prepared to provide professional support to the Middle East, helping industries quickly restore production and achieve modernization.

1. Overview of Machine Tool Demand in the Middle East

Machine tool demand in the Middle East shows two distinct trends: on one hand, war has destroyed many production facilities, creating a sudden and urgent need for basic production equipment. On the other hand, as national reconstruction gets underway, demand is shifting toward high-precision, high-efficiency machinery that can quickly restore and enhance industrial capabilities.

Demand for Traditional Machine Tools:

With the end of conflict and the launch of infrastructure rebuilding, many Middle Eastern countries require large quantities of conventional machine tools such as lathes, milling machines, and drills. These are fundamental tools widely used in metalworking, oil and gas equipment, and construction.

Demand for High-Precision Machine Tools:

Demand for high-precision equipment is increasing—particularly in aerospace, defense, and precision manufacturing. As production resumes, many countries are shifting toward high-tech industries, driving the need for more advanced machine tools.

2. Post-Conflict Infrastructure Reconstruction Needs

Following war or conflict, infrastructure rebuilding often becomes a national priority. This process involves significant construction and industrial recovery, which drives demand for various types of machine tools—especially in the following sectors:

Energy and Oil Infrastructure

The energy sector in the Middle East is heavily reliant on machine tools, particularly for the manufacturing and maintenance of oil drilling equipment and pipelines. As oil infrastructure is repaired after conflict, demand will surge for large-scale machining equipment and customized tools. For example, in oil platform construction, heavy-duty lathes and large milling machines are essential.

Construction and Civil Engineering

Rebuilding infrastructure requires extensive metalworking tasks such as rebar cutting, pipe welding, and bridge construction. The construction sector in the Middle East will see strong demand for cutting machines, bending machines, and welding machines. These tools are essential for fabricating steel structures and concrete components.

Transportation

As cities and roads are rebuilt, transportation infrastructure—including highways, railways, and airports—will also require significant investment. High-precision CNC machines will be crucial in producing complex transportation components such as engine parts, gears, and rail systems.

3. Suitable Machine Tools for Different Infrastructure Types

To support the reconstruction efforts across the Middle East, it is vital to understand which types of machine tools are best suited to different infrastructure applications. Below is a breakdown of key infrastructure sectors and the corresponding recommended equipment:

Energy Infrastructure (Oil & Gas)

Heavy-Duty Lathes and Milling Machines:

For machining large-diameter pipes, valves, and drilling equipment.

CNC Machines:

For high-precision manufacturing of components such as pump housings and generator parts.

Construction and Civil Engineering

Cutting and Bending Machines:

For processing metals like steel and aluminum, used in buildings, bridges, and towers.

Welding Machines:

For connecting and repairing metal structures, especially in heavy equipment and construction machinery manufacturing.

Transportation (Road, Rail, Aviation)

CNC Lathes and Machining Centers:

For producing engine components, transmission systems, and vehicle body structures.

High-Speed Milling and Drilling Machines:

For processing railway systems, sleepers, and precision aerospace parts.

Industrial Manufacturing

Automated Machine Tool Systems:

Suitable for automated, large-scale production lines and smart manufacturing setups.

Precision Machine Tools:

Used for producing high-precision components in electronics and high-end mechanical industries.

4. MINNUO’s Full-Cycle Value Services

As a trusted industry partner with over 15 years of experience, we understand the urgency and time sensitivity involved in post-conflict reconstruction. From oil equipment factories in Iraq to steel processing centers in Lebanon, our service teams provide "24/7 support + on-site response within 48 hours" as part of our after-sales guarantee.

More importantly, we are not just equipment suppliers—we are solution providers:

Pre-Project Planning:

Our engineers visit your facility to develop production capacity plans based on your reconstruction strategy.

Technical Empowerment:

We offer customized training programs covering machine operation and preventive maintenance. To date, we’ve trained over 3,000 technicians across the Middle East to help maximize equipment performance.

Full Lifecycle Management:

With remote monitoring systems, we track machine status in real time and issue predictive alerts. One customer in Jordan reported a 60% reduction in machine downtime after implementing our solutions.

Conclusion: Machine Tool Demand and Challenges in the Middle East

In conclusion, post-conflict infrastructure reconstruction will drive a sharp increase in demand for machine tools—especially in the energy, construction, transportation, and manufacturing sectors. Middle Eastern nations urgently need high-quality, adaptable machine tools to support their rapid industrial recovery and growth.

To meet these demands, countries in the region must import advanced equipment, enhance local manufacturing capacity, and ensure efficient production workflows. MINNUO offers one-stop solutions for the Middle East—from equipment sourcing to technical support and after-sales service. We are committed to helping clients rapidly restore production while supporting long-term modernization and efficient industrial operations.

Our high-precision machines and customized services are designed to support the rebuilding of infrastructure and the advancement of industrial capabilities throughout the Middle East.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763