How to Choose the Right Type of Turret for CNC Machine Tools?

In CNC machining, the turret is a core component responsible for mounting and switching tools. It directly impacts machining rhythm and workpiece precision. Many production issues do not originate from the cutting tools themselves, but from improper turret selection or misuse. This can result in tool change delays, increased machining errors, or even the scrapping of entire batches. For manufacturers pursuing high efficiency and precision, choosing the right turret—and ensuring its correct usage—is a key step to maximizing machine performance and ensuring stable production.

The turret is the key mechanism in CNC machines responsible for mounting and changing tools. Common turret types include electric turrets, hydraulic turrets, servo turrets, and live (powered) turrets. Choosing the most suitable one requires a comprehensive consideration of machining requirements, cost budget, maintenance capabilities, and other factors.

Let’s dive into the world of turrets, understand how they work, and help you avoid unnecessary mistakes in real-world operation.

1. Basic Definition and Core Functions of a Turret

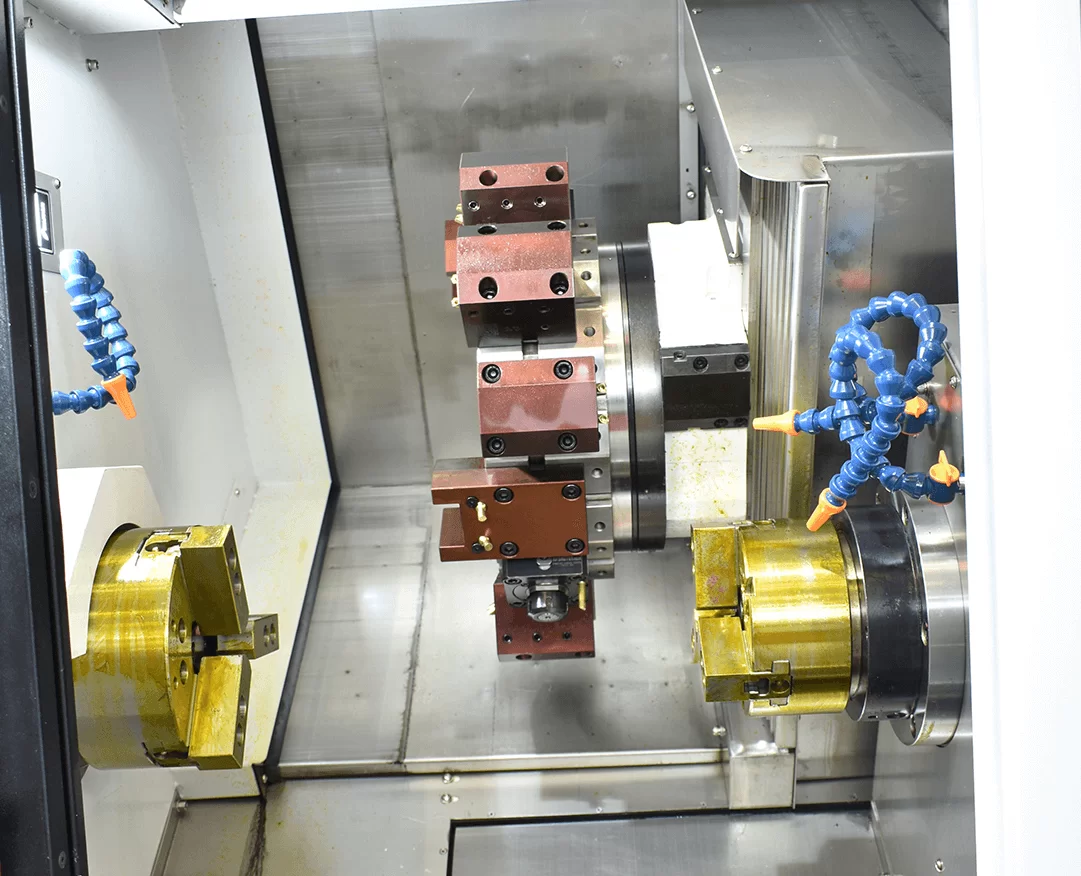

A turret is a crucial component in CNC machines that holds and switches tools. It plays a key role in achieving multi-process machining. Usually mounted beside or below the spindle, it uses specific drive and transmission mechanisms to change tools quickly and position them precisely.

Core Functions:

Automatic Tool Change: Automatically switches tools without manual intervention, significantly reducing changeover time and increasing machining speed.

Accurate Positioning: Ensures tools are precisely positioned after switching, which is critical for maintaining workpiece accuracy and product quality.

Multi-Process Support: Allows mounting of multiple tool types (drills, borers, mills, turning tools), enabling various operations in one setup.

2. Types of Turrets and Their Features

Electric Turret

Drive Method

Driven by a standard electric motor. Power is transmitted through mechanisms such as gears or worm gearsto rotate the turret.Tool Change Principle

The electric motor rotates the turret index plate according to program commands. However, electric turrets are primarily designed for switching turning tools and do not support complex tool motions like milling or drilling after indexing.Advantages

Low cost: Affordable to manufacture and purchase, ideal for small machining shops or budget-sensitive operations.

Compact structure: Space-saving design suitable for machines with limited installation space.

Easy maintenance: Low technical threshold for operators; basic maintenance is simple after minimal training.

Disadvantages

Slow tool change: Not ideal for frequent tool changes due to longer changeover time.

Limited positioning accuracy: Not suitable for high-precision machining.

Shorter lifespan: Frequent motor start/stop cycles may cause impact wear on the mechanical structure.

Suitable Applications

Best for small CNC lathes or simple part production that doesn’t demand high precision or high speed—such as small hardware components or general mechanical parts.Hydraulic Turret

Drive Method

Powered by a hydraulic system using cylinders to generate motion.Tool Change Principle

Hydraulic cylinders push and rotate the index plate. When a tool change is required, the hydraulic system actuates the cylinder to turn the turret to the target tool position.Advantages

Simple structure, low cost: Easier to manufacture and maintain, offering a budget-friendly solution.

High torque output: Excellent for heavy-duty cutting of large or hard materials.

Smooth tool change: Hydraulic movement reduces vibration during tool change, enhancing process stability.

Disadvantages

Slower tool change speed: Not suitable for high-efficiency, high-volume production.

Maintenance intensive: Risks of oil leakage; requires regular oil level checks and line inspections.

Limited positioning precision: Cannot meet strict precision requirements for high-accuracy machining.

Suitable Applications

Heavy-duty cutting applications with moderate precision requirements, such as mold making or mining equipment part machining, where torque is more critical than micrometric precision.Servo Turret

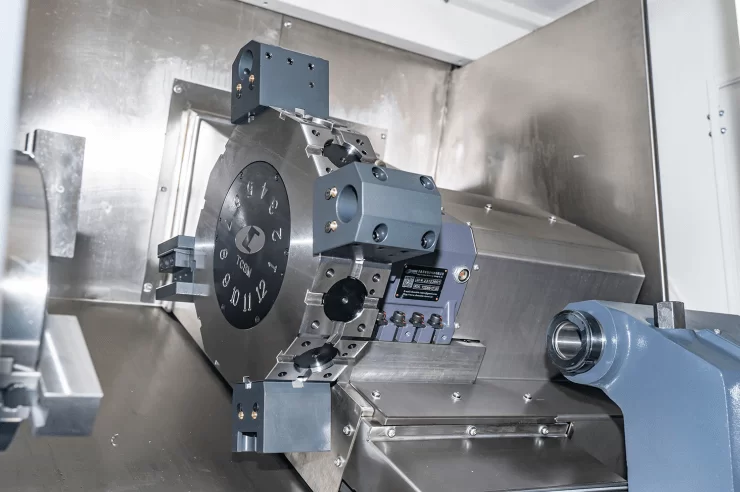

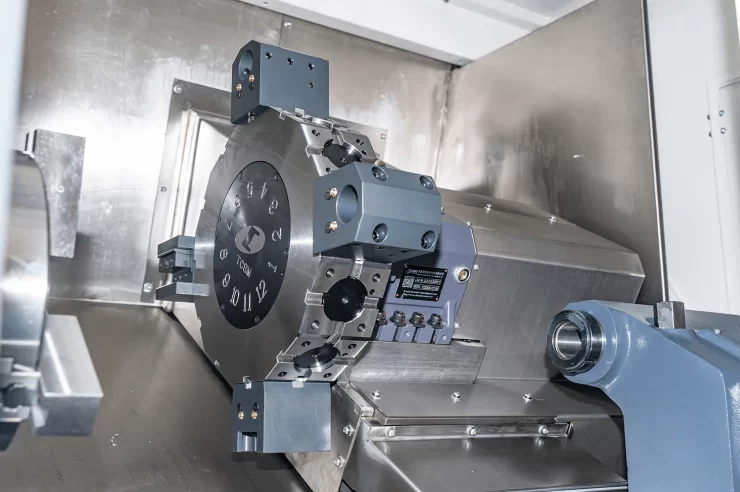

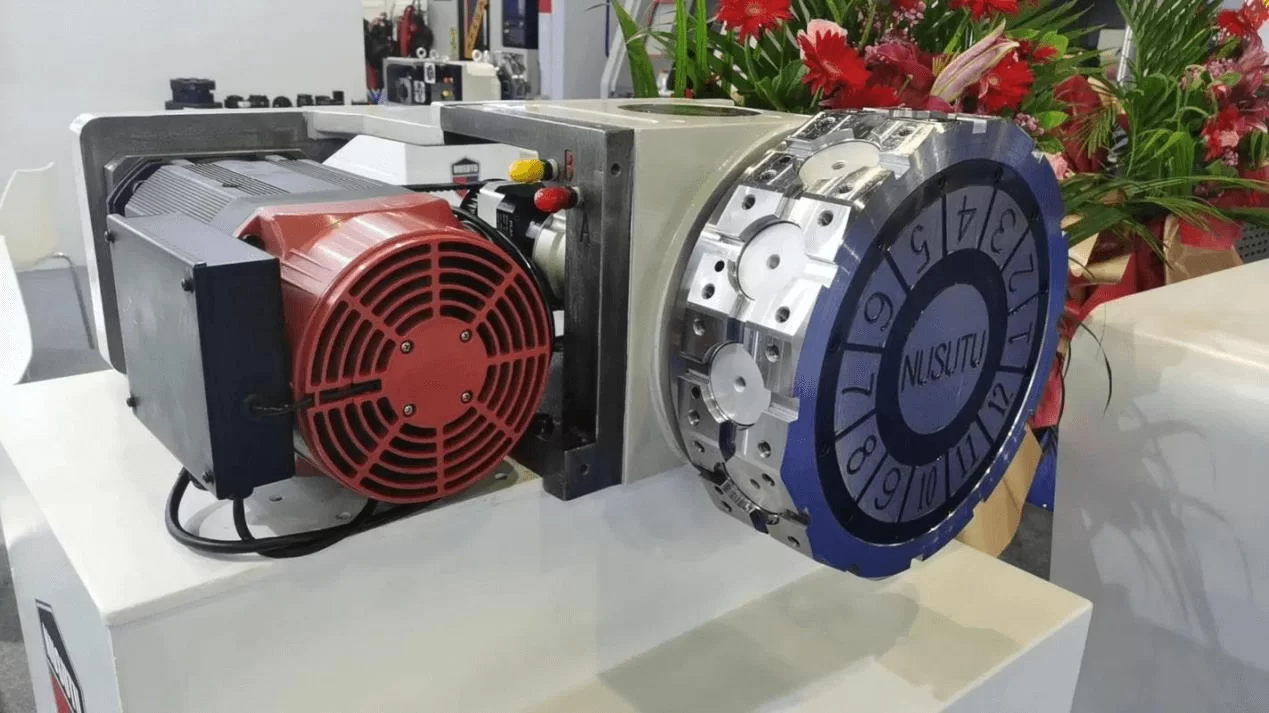

Drive Method

Driven by a servo motor equipped with a high-precision encoder, operating under a closed-loop control system.Tool Change Principle

When receiving a command, the control system signals the servo motor to rotate to the desired angle. The encoder continuously feeds position data back to the control system, ensuring highly accurate positioning at the target tool station.Advantages

High-speed tool change: Rapid response reduces changeover time, ideal for frequent tool changes.

Ultra-high precision: Closed-loop system with encoder feedback enables micron-level repeatability—perfect for precision machining.

Flexible control: Programmable parameters allow optimization of speed, acceleration, direction, and shortest tool path.

Reliable performance: Smooth operation with low vibration and noise; built-in overload protection and diagnostic features enhance uptime.

Disadvantages

High cost: Expensive components like servo motors and encoders increase upfront investment.

Higher control system requirements: Requires advanced CNC systems and skilled personnel for setup and programming.

Complex maintenance: Involves multiple disciplines—mechanical, electrical, and software—requiring trained professionals for troubleshooting and repairs.

Suitable Applications

Ideal for high-precision, high-efficiency industries such as:Aerospace: Engine casings, turbine blades

Automotive: Engine blocks, precision gears

Electronics: Precision enclosures and components

Medical: Artificial joints, dental implants

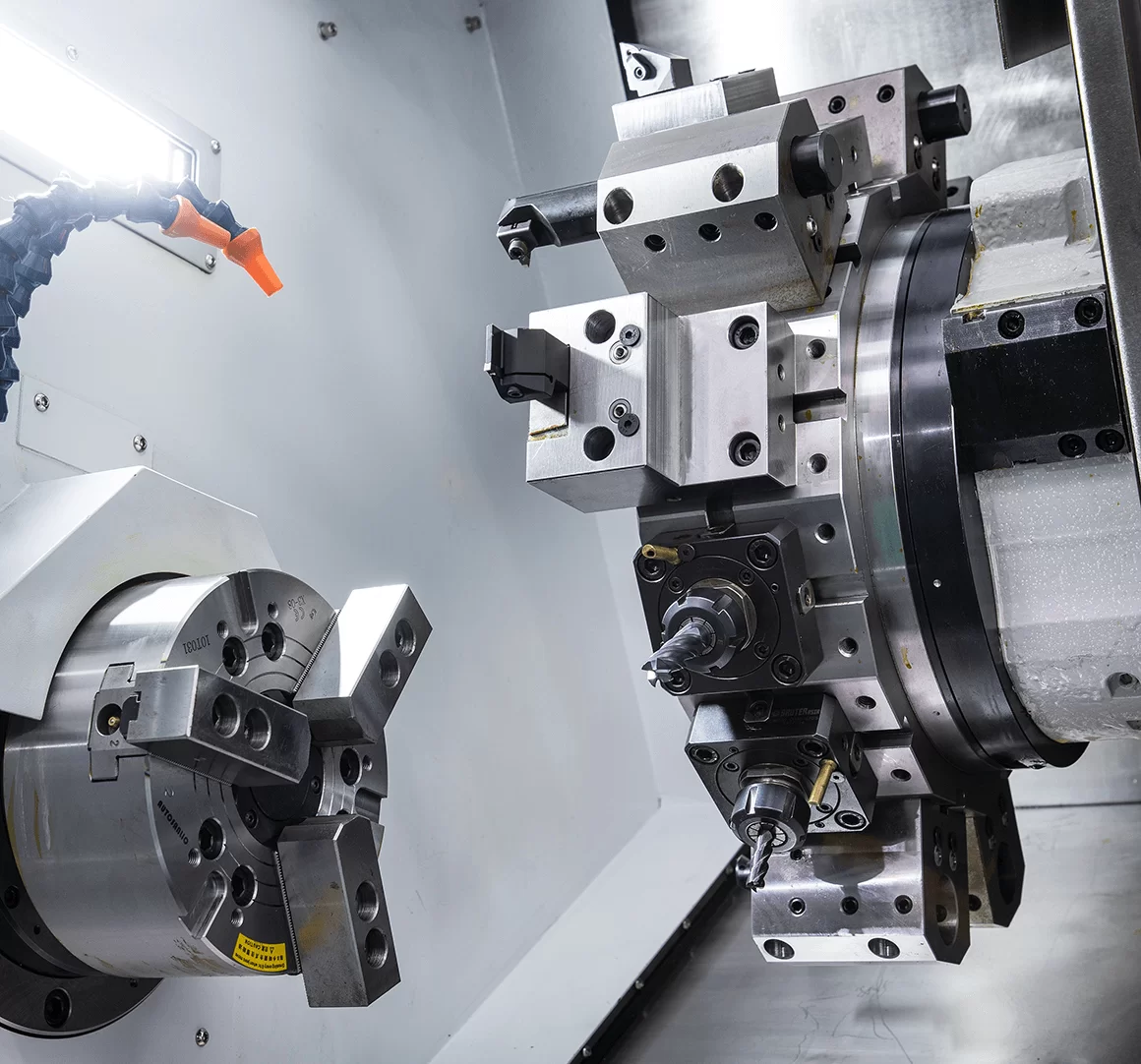

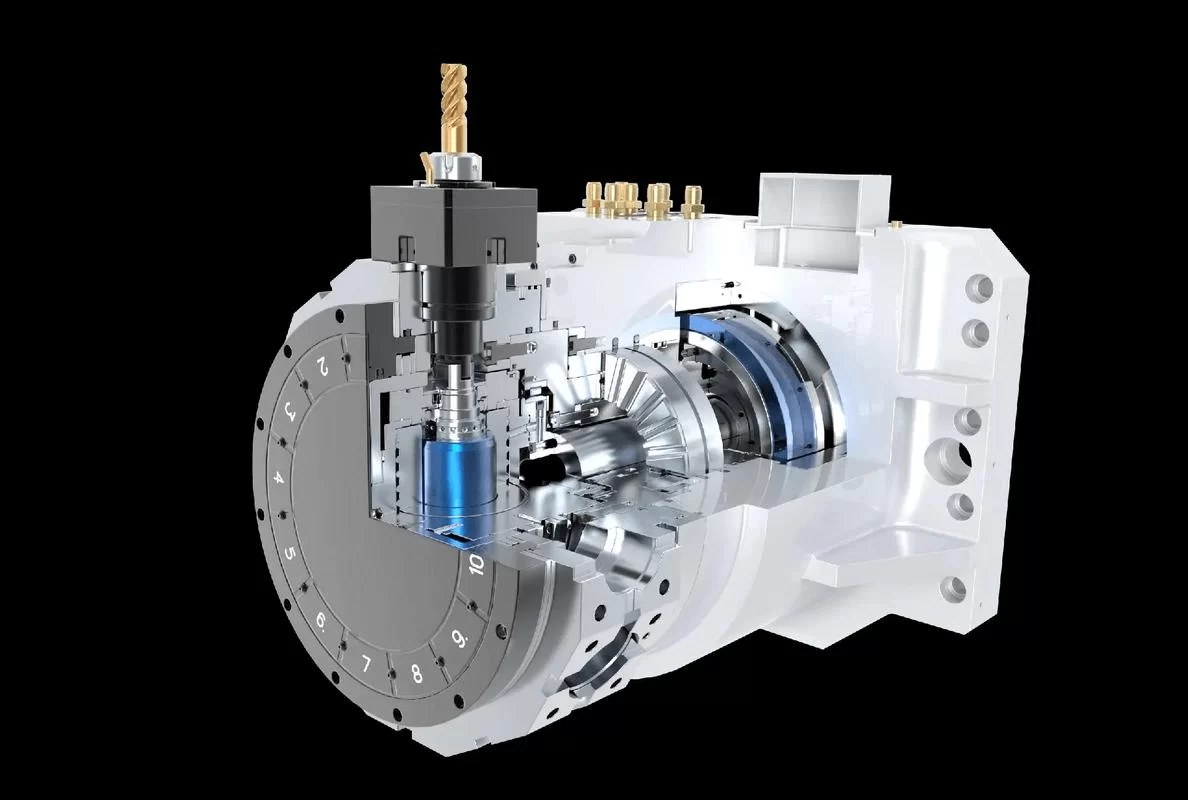

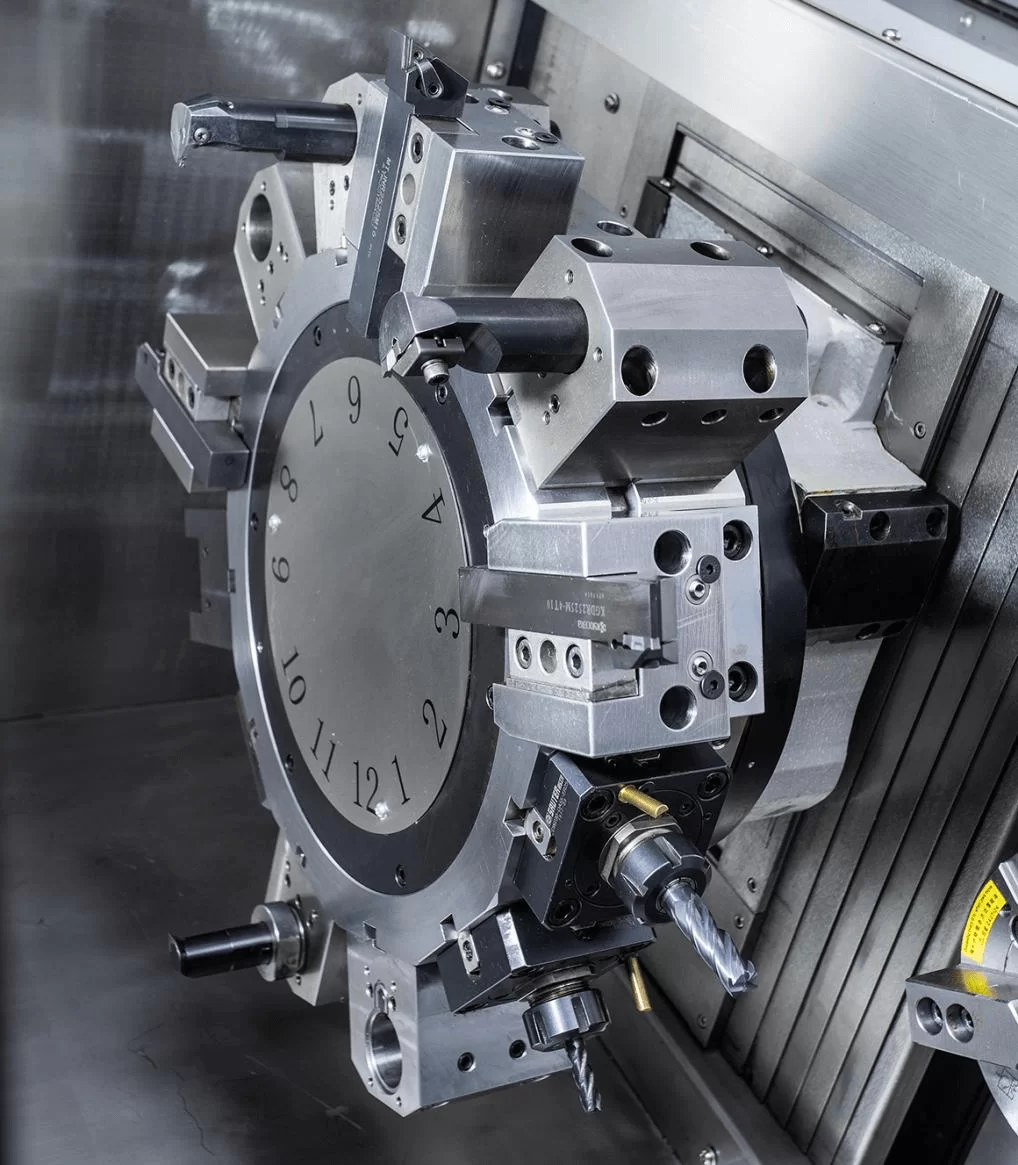

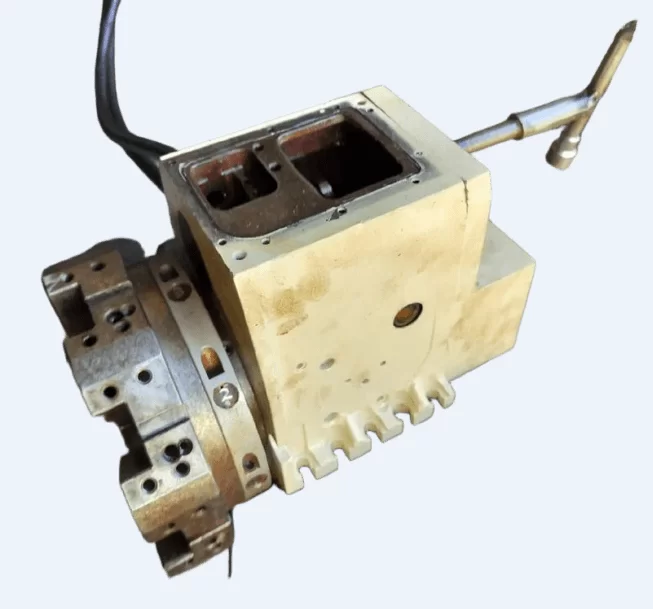

Live (Powered) Turret

Drive Method

Built upon servo or hydraulic turrets, with an added power drive unit (electric motor, hydraulic motor, etc.).Tool Change Principle

In addition to standard turret indexing, live turrets include internal drives to rotate tools—enabling milling, drilling, and other compound operations. This significantly extends machining capability.Advantages

Extensive functionality: Enables turning-milling multi-tasking on one machine, reducing part transfers.

Efficient processing: Multi-operation in a single setup increases precision and reduces cycle time.

Best for complex parts: Handles components requiring various features and combined processes.

Disadvantages

High cost: Complex structure and control systems increase manufacturing and investment cost.

High skill requirement: Operators must understand multitasking programming and workflow planning.

Difficult maintenance: Complex internals require professional diagnosis and repair.

Suitable Applications

Best for industries like aerospace, automotive, and medical devices—where parts are complex and demand high precision and multi-process integration.Summary Comparison

Type | Cost | Precision | Tool Change Speed | Application Focus |

Electric Turret | ★ | ★★ | ★★ | Basic part production, low cost |

Hydraulic Turret | ★★ | ★★ | ★★ | Heavy-duty, medium precision |

Servo Turret | ★★★ | ★★★★ | ★★★★ | High-precision, high-volume production |

Live Turret | ★★★★ | ★★★★ | ★★★★ | Complex multi-process machining |

Still having trouble choosing among these four tool turrets? No worries—Minnuo, as a solution-oriented machine tool manufacturer, will recommend the most suitable turret based on your selected machine type and machining requirements, ensuring optimal compatibility and performance between the turret and the machine.

3. Key Technical Parameters of Turrets

When selecting or using turrets, pay attention to these parameters:

Number of Tool Stations: More stations = less tool change, higher efficiency, but higher cost and complexity.

Tool Change Time: Includes rotation, positioning, and clamping. The shorter, the better.

Positioning Accuracy: Deviation between actual and target position affects machining precision. Repeatability is key.

Maximum Tool Weight and Size: Exceeding capacity leads to instability or damage—must be strictly followed.

4. Benefits of CNC Turrets in Machining

CNC turrets offer tangible production advantages:

Higher efficiency: Fast, automated tool changes reduce idle time.

Stable precision: High positioning and repeatability avoid human errors.

Expanded capability: Multi-process operations in one setup reduce setup errors.

Reduced labor intensity: Fewer manual interventions reduce fatigue and risk.

5. Common Turret Faults and Troubleshooting

Tool Change Failure

Symptoms: Incomplete tool change, jamming.

Causes: Worn transmission parts, faulty sensors, or control program errors.

Solutions: Replace worn parts, calibrate sensors, adjust system parameters.

Positioning Error

Symptoms: Size deviation after tool change.

Causes: Insufficient torque, worn ball screws, worn locating pins, incorrect parameters.

Solutions: Check servo motor, replace mechanical parts, recalibrate parameters.

Abnormal Noise

Symptoms: Knocking or grinding sounds during operation.

Causes: Lack of lubrication, loose fasteners, damaged gears/bearings.

Solutions: Re-lubricate, tighten connections, replace faulty components.

⚠ Safety During Repairs

Immediately stop the machine. Disconnect all power, air, and hydraulic sources before maintenance. Avoid contact with moving parts. Use proper tools and procedures. After repair, conduct test runs before resuming production.

6. Turret Maintenance and Care

Proper care extends turret life and ensures reliable performance.

Daily Maintenance

Clean the turret surface of oil, chips, and debris.

Check tool holders for tightness or deformation.

Lubricate per schedule using proper grease/oil.

Check and tighten bolts/nuts regularly.

Scheduled Maintenance

Every 1000 hours (or as needed), inspect mechanical parts (gears, racks, ball screws, guides).

Check motors, sensors, wiring for damage.

For hydraulic turrets, inspect oil level, quality, and hydraulic components.

Test and calibrate control systems; update software and backup settings.

7. Conclusion

As a vital part of CNC machines, turrets play a crucial role in enhancing efficiency, ensuring accuracy, and enabling multi-process machining. Each turret type has its strengths and trade-offs. Choosing the right turret depends on machining requirements, budget, and maintenance capabilities.

As a solution-oriented machine tool manufacturer,Minnuo offers turret recommendations tailored to your machine model and processing needs—ensuring seamless turret-machine integration and optimal performance.

If you have further questions about turret selection, feel free to contact Minnuo. We’re ready to provide professional, free consultation to support your production success.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763