Regular maintenance

320×400mm Table · 250×350mm Travel · 50–350mm Max Distance from Director to Worktable

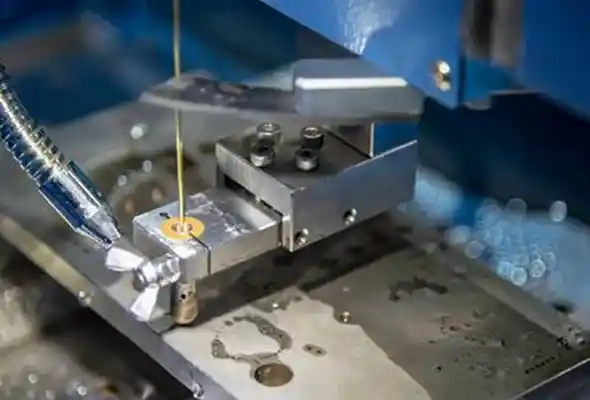

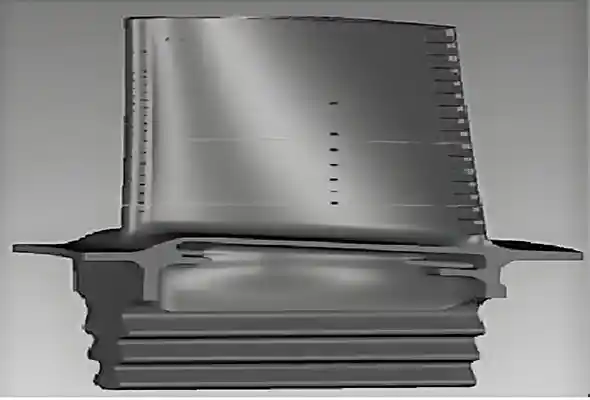

The DS703A is a compact, high-speed EDM drilling machine built for precise, rapid creation of micro-to-small diameter holes in conductive materials. With a flexible electrode range from φ0.3 to φ3mm, it is especially effective for drilling cooling holes, jet nozzles, and wire EDM start holes. The rigid column, fine-feed axis, and high-speed servo system make it a versatile choice for toolmakers and aerospace manufacturers.

DS703A Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● 400×300mm worktable fits various small and medium workpieces with stable layout.

- ● 250×200mm travel range supports multi-position batch processing.

- ● Drills holes from φ0.3mm to φ3mm for micro-feature applications.

- ● Integrated dielectric and flushing system ensures hole straightness and cooling.

- ● Fast setup and automatic electrode feed improve daily productivity.

Recommended Configurations

- ● Servo Z-axis controller: Enables precision depth control and adaptive feed rates.

- ● Auto flushing booster: Maintains flushing pressure for deep hole stability.

- ● Electrode chuck set (multi-size): Accommodates full range from φ0.3–φ3mm tubes.

- ● CCD hole position visual system: Speeds up alignment on molds and hardened blocks.

- ● Graphite electrode compatibility: Expands capability to EDM-sensitive materials.

Application Case

- ● Client: Aerospace Component Manufacturer – Canada.

- ● Use Case: Drilling micro cooling holes in turbine blade root and wire EDM starter holes in hardened tool steel.

- ● Setup: DS703A with φ0.5mm brass electrodes, dual booster pump flushing, servo Z-axis module.

- ● Results: Hole diameter accuracy: ≤ ±0.015 mm, straightness within 20×D depth: ≤ 0.03 mm deviation, setup time per workpiece: < 3 minutes, client feedback: “Essential equipment in our EDM pre-processing—the DS703A is compact, fast, and surgically precise.”

Product Specifications

| Specifications | Unit | DS703A |

|---|---|---|

| Worktable size | mm | 400*300 |

| Worktable travel | mm | 250*200 |

| Serve travel | mm | 330 |

| Spindle Travel | mm | 200 |

| Electrode diameter | mm | φ0.3-φ3 |

| Max.working current | A | 22 |

| Power input | 380V/50Hz 3.5kW | |

| Machine weight | kg | 600 |

| Dimension(L*W*H) | mm | 1070*710*1970 |

Catalog

Frequently Asked Questions

Minnuo’s EDM drilling machines are perfect for hard materials and components like aerospace turbine blades, mold cooling holes, nozzles, ejector pins, and fuel injectors, requiring fine and deep hole drilling.

EDM drilling can process hardened steel, stainless steel, titanium, carbide, copper, aluminum, and nickel-based alloys, regardless of material hardness.

Minnuo’s EDM drills can produce holes from Ø0.3 mm to Ø6.0 mm, with depth-to-diameter ratios exceeding 300:1, achieving high aspect ratio deep holes efficiently.

Absolutely! Just send us the hole diameter, depth, material, and production volume, and Minnuo’s engineers will recommend the most suitable EDM drilling machine model within 10 minutes.

Yes! We offer customizations for maximum machining depth, machine table size, dielectric system configuration, automatic electrode changers (AEC), and CNC or manual control systems.

Minnuo EDM drills use servo-controlled feed systems, high-frequency pulse power supplies, real-time monitoring systems, and undergo sample testing and calibration before delivery.

Standard models can be delivered within 20–30 working days. Customized or special configurations usually require 30–45 working days.

Minnuo provides a one-year warranty, 24/7 technical support, free online training, remote troubleshooting, and lifetime spare parts service.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763