What Is a Dual-Spindle CNC Lathe and What Are Its Advantages?

If you're wondering how manufacturers can rapidly mass-produce precision parts while keeping error margins extremely low, dual-spindle CNC lathes are often the key equipment.

A dual-spindle CNC lathe is an advanced machining tool equipped with two independent spindles, enabling multi-surface machining and continuous process handling either synchronously or independently. This significantly enhances both production efficiency and machining accuracy.

Next, we’ll explore the features, working principles, and why this type of machine plays a vital role in modern manufacturing.

I. What Is a Dual-Spindle CNC Lathe?

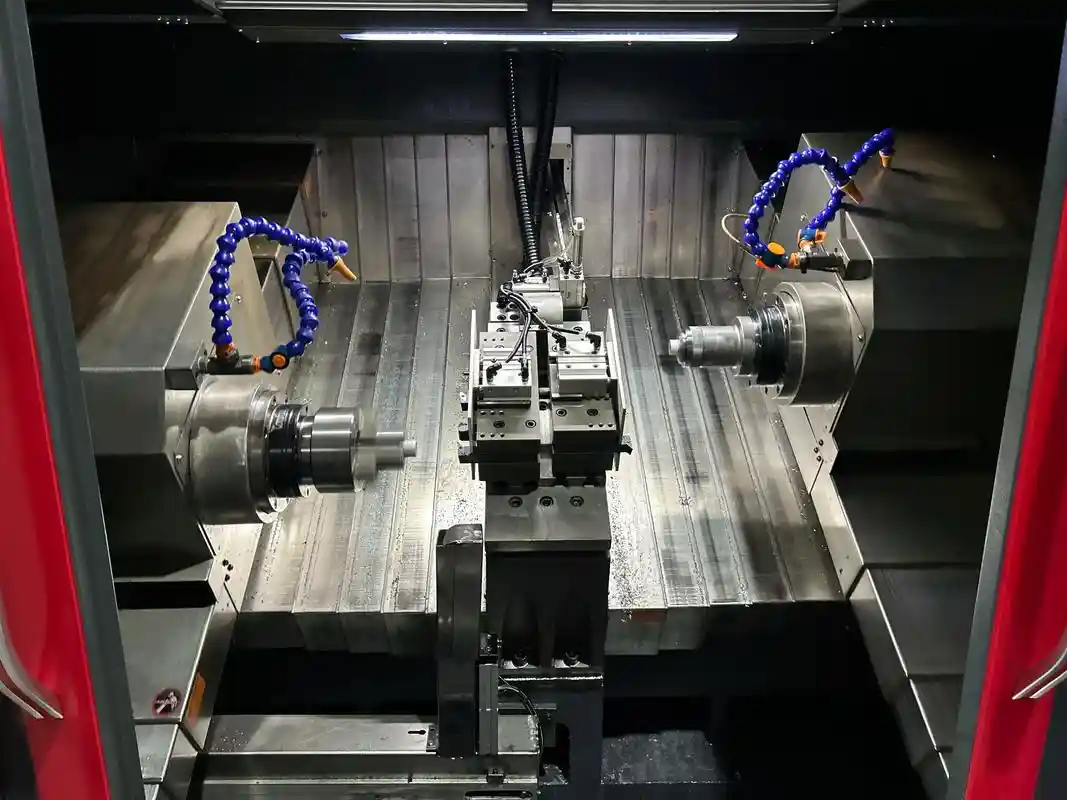

A dual-spindle CNC lathe is a type of precision machining equipment distinguished by its two spindles—unlike conventional single-spindle lathes. These two spindles can operate independently or in coordination, depending on the processing needs.

The core purpose of this design is to enhance machining efficiency. By simultaneously processing different parts of a workpiece or seamlessly connecting different processes, it reduces waiting time and ensures continuous production flow.

II. Key components of dual-spindle machine tools

To understand how a dual-spindle CNC lathe operates, we need to examine its main components:

Dual Spindles:

The primary working units, which come in parallel or front-and-back configurations. Driven by servo motors, they typically offer speeds ranging from 50 to 6000 r/min, adjustable based on material and process requirements. Their main function is to hold and rotate the workpiece, providing stable motion for the cutting tool.

The primary working units, which come in parallel or front-and-back configurations. Driven by servo motors, they typically offer speeds ranging from 50 to 6000 r/min, adjustable based on material and process requirements. Their main function is to hold and rotate the workpiece, providing stable motion for the cutting tool.

Bed:

Made from high-strength cast iron using resin sand casting, the bed provides rigidity and vibration damping. It features hardened sliding or rolling guideways, the latter offering lower friction and positioning accuracy up to 0.001 mm, ensuring stable movement and minimizing vibration-related errors.

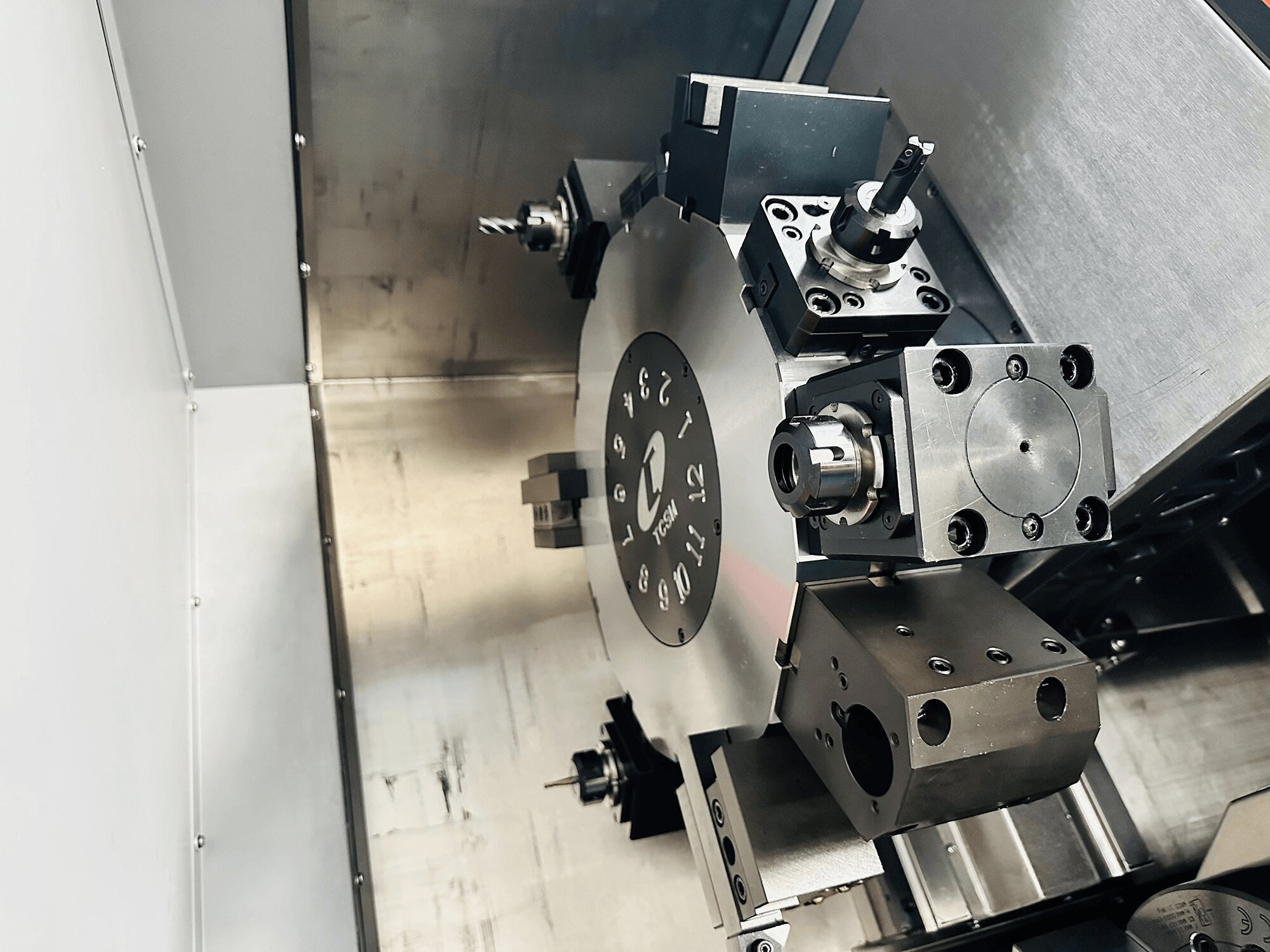

Turret:

Available in electric or hydraulic models, these turrets can hold 8–12 different tool types. Indexing time is usually 0.3–0.5 seconds, allowing rapid tool changes and minimal process transition time.

Available in electric or hydraulic models, these turrets can hold 8–12 different tool types. Indexing time is usually 0.3–0.5 seconds, allowing rapid tool changes and minimal process transition time.

CNC System:

Mainstream systems include FANUC and Siemens, with multi-axis linkage control. These systems interpret G-code and M-code generated from CAD/CAM, calculating spindle speed, feed rate, etc., and control all motion trajectories with positioning accuracy within ±0.002 mm.

Feed System:

Comprising servo motors, ball screws, and guideways. Ball screw lead error is typically within 0.01 mm/300 mm, and combined with pulse-controlled servo motors, allows for high-precision linear and arc motion.

Auxiliary Units:

Cooling systems use pump-fed oil with flow rates of 20–50 L/min to dissipate heat. Lubrication is time- and quantity-controlled to reduce wear. Chip removal systems, whether chain-type or screw-type, ensure efficient chip disposal.

III. Technical Classification and Cooperative Control of Dual Spindles

The technical variations in dual-spindle CNC lathes mainly lie in spindle layout and coordination, which determine their application scope and performance.

By Spindle Layout:

Parallel Dual-Spindle:

Spindles are aligned parallel at the same height, commonly used for symmetrical parts. For example, both ends of a long shaft can be machined simultaneously, preventing deformation caused by single-end operations.

Front-and-Back Dual-Spindle:

Spindles are aligned longitudinally. The front spindle handles roughing while the rear spindle finishes the part, with workpieces automatically transferred via a manipulator. Suitable for complex parts needing multiple continuous processes.

Spindles are aligned longitudinally. The front spindle handles roughing while the rear spindle finishes the part, with workpieces automatically transferred via a manipulator. Suitable for complex parts needing multiple continuous processes.

Compound Dual-Spindle:

Combines the above two layouts with a rotating worktable for flexible spindle direction switching. It balances symmetrical and continuous processing but has higher structural complexity and cost.

By Spindle Coordination:

Rigid Synchronous Control:

CNC system locks both spindles’ movement parameters to ensure identical speed and direction, maintaining errors within ±1 r/min—ideal for high-symmetry parts like engine balance shafts.

Flexible Coordinated Control:

Allows different spindle parameters per process. For example, rough turning at 3000 r/min on one spindle and face milling at 5000 r/min on the other. The system synchronizes in real time to prevent interference.

Dynamic Error Compensation:

Linear encoders on the spindles monitor position deviations in real time, and the system compensates every 1 ms, keeping synchronized movement error within 0.001 mm—critical for high-precision part consistency.

IV. Why Choose a Dual-Spindle Machine? Key Advantages

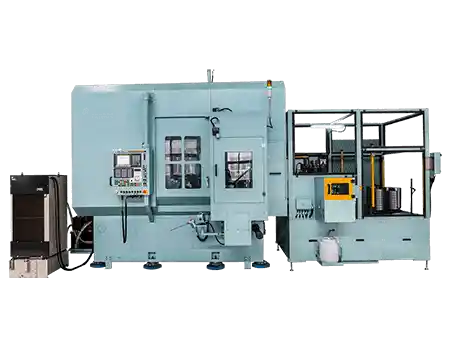

Dual-spindle simultaneous machining reduces single-part cycle time by 30%–50%. For example, a 100 mm shaft takes 80 seconds on a single-spindle lathe but only 45 seconds on a dual-spindle one. Minnuo’s MN700D, through optimized synchronization algorithms, further boosts efficiency by 15% over conventional dual-spindle machines.

Higher Accuracy:

Fewer clamping operations reduce positioning errors. Repeatability can reach 0.003 mm, ensuring dimensional consistency in batch production.

Lower Labor Cost:

High automation allows one operator to oversee 2–3 machines, cutting labor demand by 50% compared to single-spindle setups.

Better Space Utilization:

A dual-spindle lathe occupies about 2–3㎡ but matches the capacity of two single-spindle machines, improving space efficiency by over 40%.

V.Application Fields

Dual-spindle CNC lathes are widely used in:

Automotive Manufacturing:

For parts like engine crankshafts (IT6 accuracy) and gearbox shafts, supporting production volumes over 100,000 units annually.

Aerospace:

For turbine shafts and landing gear components. Often involves titanium or high-temperature alloys requiring high speed (3000–5000 r/min) and heavy feed—areas where dual-spindle machines excel in stability.

Medical Devices:

For artificial joints, surgical tools, etc., demanding surface roughness of Ra ≤ 0.8μm. The high precision of dual-spindle machines meets these requirements.

Mold Making:

For guide posts and bushings in molds. When combined with precision grinding, can achieve IT5-level dimensional accuracy.

VI.Comparison with Other Lathes

Feature | Dual-Spindle CNC Lathe | Single-Spindle CNC Lathe | Manual Lathe |

Production Speed | Fast (dual-process parallel) | Medium (single-process sequential) | Slow (manual feed) |

Positioning Accuracy | ±0.002 mm | ±0.003 mm | ±0.02 mm (operator-dependent) |

Automation | High (robotic loading/unloading) | Medium (requires manual assistance) | Low (fully manual) |

Ideal Batch Size | Large (1000+ pcs) | Medium (100–1000 pcs) | Small (1–100 pcs) |

Equipment Cost | High (¥500,000–¥1.5 million) | Medium (¥200,000–¥800,000) | Low (¥50,000–¥200,000) |

VII.Maintenance Tips for Dual-Spindle Machines

Daily Checks:

Before startup, check spindle bearing temperature (≤ 40℃), and inspect guideways for scratches. Weekly turret positioning error check (≤ 0.005 mm allowed).

Lubrication:

Lubricate ball screws with lithium grease every 200 hours. Replace guideway oil every 500 hours, maintaining oil level at the midpoint of the sight glass.

Coolant Management:

Test coolant concentration monthly (5%–8%), and replace it every 3 months to prevent bacterial buildup and pipe clogging.

System Care:

Weekly backup of CNC parameters and clean fan filters every 6 months to prevent overheating failures.

Tool Maintenance:

Regrind HSS tools after 50–100 pieces, replace carbide tools every 500–1000 pieces to ensure consistent cutting performance.

VIII.Safety First: Machine Tool Operating Precautions

Training:

Operators must know emergency stop locations and axis limits. Independent operation only after certification.

Clamping Check:

After clamping, run a test (spindle at 50–100 r/min) to confirm no wobble or slippage.

Monitoring During Operation:

Never open the safety door or touch rotating parts while in motion. Always pause before inspection or measurement.

Work Area Management:

Keep the area clean. Chip piles should not exceed guard height. No water/oil on the floor to prevent slips.

IX.Conclusion

Whether you’re a manufacturing professional or someone interested in precision machining technology, understanding dual-spindle CNC lathes is essential. If you still have questions or are looking for a suitable dual-spindle lathe to enhance your production, visit Minnuo’s websiteand contact us anytime. We are ready to provide expert answers!

Email

Email sales1: +86 13295238763

sales1: +86 13295238763