Regular maintenance

φ220mm Max Workpiece Diameter · φ100mm Max Hobbing Cutter Diameter · 200mm Max Hobbing Cutter Length

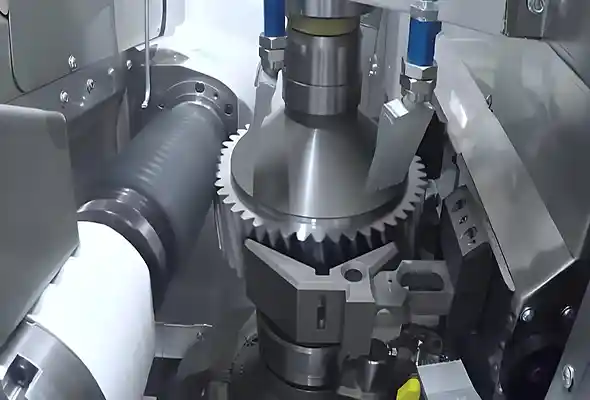

The YD3132 CNC Dry Gear Hobbing Machine features a 10-axis configuration with dual-channel, two-station architecture designed for ultra-efficient gear machining. This model integrates both linear and rotary axes for high-speed, dry-cut hobbing of precision gears, eliminating the need for coolant and minimizing post-process cleaning.

YD3132 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● 10-axis CNC control with synchronized linear and rotary movements

- ● Dual-channel and two-station structure for parallel gear cutting operations

- ● Supports dry hobbing with optimized chip evacuation and reduced tool wear

- ● Max. workpiece diameter of φ220mm for broad gear manufacturing capability

- ● Quick-change fixture system for flexible part adaptation

- ● Integrated Siemens or Fanuc controller with gear-specific macro cycles

Recommended Configurations

- ● Accessory: Coated Carbide Hobs Function: Tailored for dry-cutting efficiency and tool longevity.

- ● Accessory: Rotary Tailstock Unit Function: Improves clamping stability during high-speed cuts.

- ● Accessory: Automatic Chip Conveyor with Dust Extraction Function: Keeps dry cutting clean and efficient.

- ● Accessory: Fast-Change Dual Fixture System Function: Minimizes setup time for batch or mixed production.

- ● Accessory: Smart Temperature Compensation Module Function: Maintains tolerance under long shift workloads.

- ● Accessory: Integrated Gear Inspection Probe Function: For inline quality checks without part removal.

Application Case

- ● Client: EV Powertrain Gear Manufacturer – South Korea

- ● Use Case: Simultaneous dry hobbing of small-module gears for electric vehicle transmissions

- ● Setup: YD3132 with coated hobs, dust extraction, and inline gear measurement system

- ● Results: Cycle time reduction: 40% faster vs single-station hobbers Surface roughness (Ra): ≤ 0.8 μm without post-processing Tool life extension: 2x longer using optimized dry-cut hobs

- ● Client feedback: “YD3132 brought speed and sustainability together — we’ve upgraded 3 lines with this dual-station platform.”

Product Specifications

0

Catalog

Frequently Asked Questions

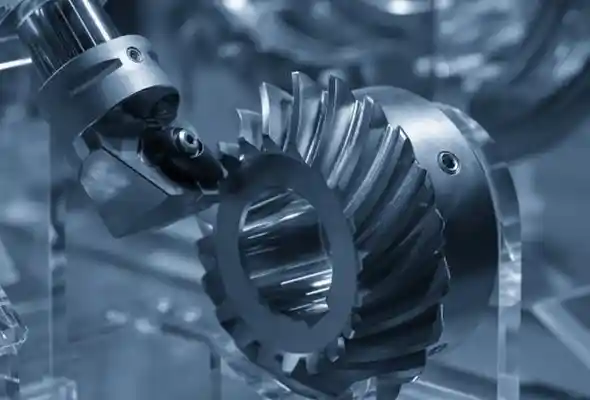

Minnuo’s gear machines are capable of producing spur gears, helical gears, bevel gears, worm gears, sprockets, and splined shafts, covering a wide range of industrial gear needs.

We offer a complete range including gear hobbing machines, gear shaping machines, gear grinding machines, and gear skiving machines, suitable for different gear machining requirements.

Our gear machines achieve gear quality up to DIN 5–7 levels for grinding, and DIN 8–10 levels for hobbing or shaping, depending on the model and process.

Of course! Provide your gear drawings or technical specifications, and Minnuo’s engineers will recommend the most suitable gear machine model within 10 minutes. Complete gear production line solutions are offered within 5 working days.

Absolutely! We offer customization including worktable size, maximum machining diameter, module range, spindle speed, CNC control brands, and automation integration like robot loading/unloading.

We use high-grade Meehanite cast structures, precision spindles, and all machines undergo gear profile accuracy testing, spindle dynamic balance tests, and full cutting trials before delivery.

Standard models are delivered within 40–60 working days. Custom-built high-end gear machines may require 60–90 working days, depending on the complexity.

Minnuo provides a one-year warranty, 24/7 technical support, remote diagnostics, on-site services, and long-term spare parts supply (guaranteed for 10+ years).

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763