What Is a Horizontal Machining Center (HMC) and Why Do You Need One?

Defining the Core of Modern Production

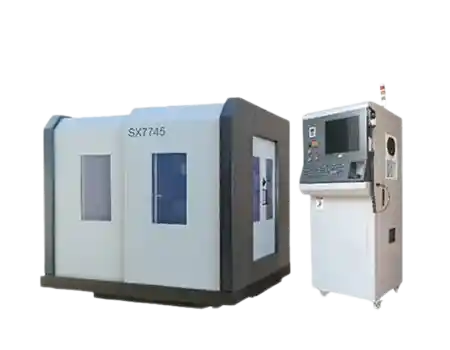

In the highly competitive world of precision manufacturing, choosing the right machine tool is paramount. While Vertical Machining Centers (VMCs) are common, the Horizontal Machining Center (HMC) stands out as a high-productivity powerhouse.

An HMC is a sophisticated CNC machine tool distinguished by the orientation of its spindle: it is set parallel (horizontal) to the worktable and the floor. This structural difference enables superior automation and efficiency, making HMCs a transformative investment for production shops globally.

This guide will provide a deep dive into the HMC, exploring its core mechanism, comparing it to its vertical counterpart, and highlighting why its advanced capabilities, particularly in 5-axis configurations, are indispensable for complex, high-volume work.

The Mechanism and Fundamental Advantages

The design of the Horizontal Machining Center facilitates several key technical benefits that directly translate into operational efficiency:

1. Superior Chip Evacuation

Perhaps the most crucial advantage of the horizontal orientation is efficient chip management. Because the spindle is positioned on the side, gravity naturally causes metal chips and debris to fall away from the cutting area and the work surface. This characteristic:

Improves machining accuracy by keeping the cutting tools and workpiece clear.

Reduces downtime, as operators do not need to frequently stop the machine to clean chips.

2. Automation and High Spindle Utilization

HMCs are built for continuous, unattended operation, often incorporating features such as:

Automatic Tool Changers (ATC): This feature, differentiating a Machining Center from a standard milling machine, allows for quick tool swaps based on program instructions.

Dual Pallet Changers: Many HMCs come equipped with two work pallets. While a part is actively being machined on one pallet, the operator can simultaneously set up the next part on the second pallet. This near-continuous operation can boost spindle utilization rates to over 90%, dramatically lowering overall cycle times.

3. Multi-Sided Machining in a Single Setup

Unlike VMCs, where a workpiece must often be clamped and reclamped multiple times to machine five sides of a block, HMCs excel at multi-face machining.

By integrating a rotary table (often designated as a B-axis, C-axis, or full 4th axis), the HMC can index and present multiple sides of the workpiece to the tool without the operator having to physically intervene.

This ability to machine multiple features in a single clamping reduces handling, eliminates stacking errors, and ensures higher geometric accuracy. HMCs are therefore ideal for tasks like complex gear cutting, slot cutting, and working on large or heavy parts that are difficult to flip.

The Power of 5-Axis Horizontal Machining

For manufacturers tackling the most challenging parts in aerospace, automotive, and medical fields, the 5-Axis HMC is the peak solution.

A 5-axis HMC adds two rotary axes (A, B, or C) to the standard X, Y, Z linear axes. This allows the cutting tool to approach the workpiece from virtually any angle, enabling:

Machining of Complex Geometries: High-precision, intricate parts (such as monolithic aerospace components) can be machined completely in one single setup, maximizing quality and minimizing lead time.

Cutting Tough Materials: Specialized 5-axis HMCs, like Makino's T-Series, are engineered with extreme rigidity and advanced thermal control systems (including ball screw and spindle cooling) to handle hard metals like titanium and nickel-based alloys, offering superior tool life and metal removal rates.

Integration with Automation: These high-end machines are designed to integrate seamlessly with robotic loading systems and automated pallet pools, achieving "lights-out" manufacturing over nights and weekends.

Disadvantages and Investment Justification

While HMCs deliver exceptional performance, they do require a significant upfront commitment:

| Consideration | Detail | Justification |

| Cost | HMCs are notably more expensive than VMCs (often starting in the hundreds of thousands of dollars). | The increase in productivity, reduced cycle times, and ability to handle high-value complex parts quickly leads to a lower cost per part. |

| Footprint | Traditional HMCs require a larger base installation area than VMCs. | Innovative models (like Brother's compact BT30 HMCs) are addressing this, offering high cutting capacity in a smaller physical footprint. |

| Complexity | The structure is more complex, potentially requiring more specialized programming and maintenance skills. | This complexity unlocks the ability to insource more projects and take on previously impossible work, expanding business growth. |

Conclusion: The Future of High-Productivity Machining

The Horizontal Machining Center (HMC) is not just an alternative to the VMC; it represents a dedicated commitment to high-efficiency, multi-sided, and highly automated production.

From fundamental advantages like gravity-assisted chip evacuation and pallet automation to the transformative capabilities of 5-axis technology, the HMC is engineered to minimize non-value-added time and maximize precision. For production shops aiming to achieve the lowest cost per part, manage complex geometries, and scale up unattended operations, investing in a robust HMC is the clear path to maintaining a globally competitive edge.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763