Regular maintenance

500×500mm Rotary Table · 780/750/800mm Travel · Built for Automated, Multi-Face Machining

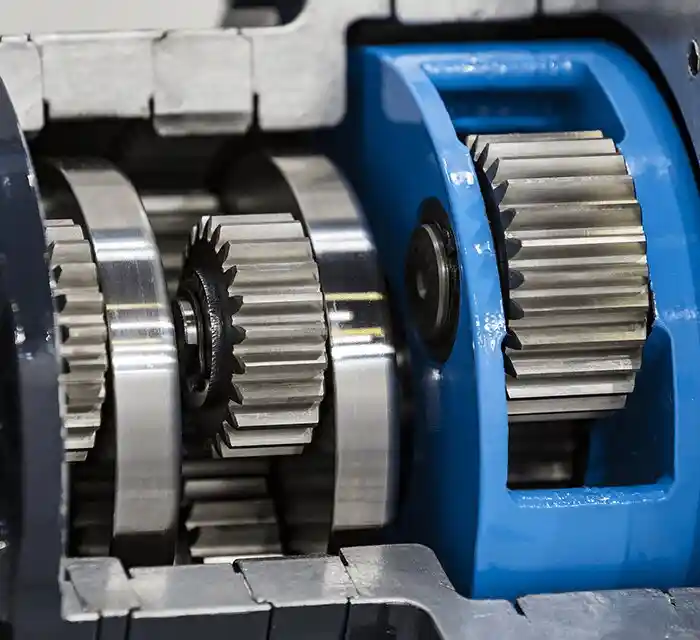

The FMC Series is a high-efficiency horizontal machining center engineered for automated multi-face machining of small-to-medium components. Featuring a 500×500mm rotary table, a maximum load of 400 kg, and axis travel ranges of 780mm (X), 750mm (Y), and 800mm (Z), this series offers both precision and production-level throughput.

FMC Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Rotary Table 500×500mm:Enables full 4-face machining of box-type parts in one clamping cycle, reducing repositioning time.

- ● Max. Load Capacity 400kg:Supports medium-weight components such as castings, valve bodies, and gear housings.

- ● Generous Axis Travels:X: 780mm · Y: 750mm · Z: 800mm — suitable for deep cavity parts and large profiles.

- ● Horizontal Layout with Superior Chip Evacuation:Gravity-assisted chip removal improves tool life, surface quality, and coolant flow.

- ● FMS Compatible:Ready for integration with pallet pool systems, loading arms, and line-side automation.

Recommended Configurations

- ● Worktable Configuration: Horizontal Rotary Worktable, Dual Pallet System, High-Precision Rotary Worktable (B-axis + C-axis)

- ● Spindle Configuration: High-Precision Spindle, Water-Cooled Spindle, High-Torque Spindle

- ● Cooling System Configuration: Internal Cooling System, High-Pressure Cooling System, Mist Cooling System

- ● Automation Configuration: Automatic Tool Changer System (ATC), Automatic Tool Measurement System (ATMS), Automatic Loading and Unloading System

- ● CNC Control System: High-Performance CNC System (FANUC, Siemens, GSK, KND, SYNTEC, Mitsubishi, etc.)

- ● Precision Assurance Configuration: Laser Interferometer Precision Measurement System, Thermal Compensation System, Grating Scale Feedback System, Encoder System

- ● Drive System Configuration: High-Load Servo Motor Drive, High-Speed Servo Motor

- ● Safety and Protection Configuration: Full Enclosure Safety Guard, Emergency Stop System

Application Case

- ● Client: Precision machinery subcontractor (Europe)

- ● Workpiece: Aluminum gear housing (cast)

- ● Setup: FMC with pallet changer, 60T ATC, rotary table, Renishaw probing system

- ● Results:4-face machining completed in one setup with zero manual flipping,Part cycle reduced by 45% vs vertical machine with manual turning,Surface finish achieved Ra ≤ 1.0μm,Accuracy within ±0.006mm over 300mm profile,24/7 operation with robotic loader and night shift autonomy

Product Specifications

| Specification | Unit | FMC4008 | FMC5008 |

|---|---|---|---|

| Table size | mm | 400×400 | 500×500 |

| Max.table load | kg | 400 | 400 |

| Table indexing(A×C) | ° | 1°×360° | 1°×360° |

| Number of switching tables | 8 | 8 | |

| Travel X/Y/Z | mm | 630/620/710 | 780/750/800 |

| Rapid Movement Speed | m/min | 60 | 54 |

| Spindle speed | rpm | 10000 | 8000 |

| Tool shank form | BT40 | BT50 | |

| Tool magazine capacity | 40 | 40 | |

| Tool change time | s | 1.2(Tool-tool)3.4(Cutting-cutting) | 2(tool-tool)4.2(Cutting-cutting) |

| Max.tool weight | kg | 8 | 25 |

| Max.tool diameter | mm | φ82φ150 | φ115φ270 |

| Max.tool length | mm | 350 | 500 |

| Workstation switching time | s | 5 | 6 |

| Machine weight | kg | 10000 | 19000 |

| Machine floor space | mm | 4000×7400 | 4090×7955 |

Catalog

Frequently Asked Questions

In a 5 axis horizontal machining center, linear guides have the advantages of high speed, low friction, and good accuracy retention, but relatively weak load - carrying capacity. Rolling guides have strong load - carrying capacity and good rigidity, but are limited in speed improvement and have relatively large friction.

For complex part processing, the 5 axis horizontal machining centeris better for parts with multiple complex side features, while the vertical machining center excels for those with vertical walls and top features. It depends on the part's geometry and processing requirements.

As a professional 5 axis horizontal machining center manufactor, Minnuo offers direct factory sales. We will provide the most suitable quotation according to customers' requirements to ensure the highest cost - performance ratio.

Minnuo has a strong and responsive pre - sales department. As long as you have the drawings, we can recommend a single horizontal machining center within 10 minutes. For a production line composed of multiple machines, we will provide a solution within 5 working days!

Minnuo has a complete set of basic production equipment. We can provide customization services for machine systems, spindle speeds, motor powers, and even the sheet metal of the outer shell.

Our company has several processing master machines of international first - tier brands, which ensures the processing accuracy of 5 axis horizontal machining center components. At the same time, we also provide a quality inspection report when the machine leaves the factory.

We have stock for conventional models of horizontal machining centers and can deliver them quickly. For customized models, delivery can be made within 30 - 45 working days.

Our horizontal machining centers come with a one - year warranty. During the warranty period, we provide free repair services. If the equipment malfunctions, customers can contact our after - sales team at any time. We provide 24 - hour technical support services and can quickly solve problems through remote video, phone calls, or on - site services.

The main difference between a horizontal and vertical machining center is the orientation of the spindle—horizontal centers have a horizontally oriented spindle, ideal for heavy cutting and chip evacuation, while vertical centers have a vertically oriented spindle, better suited for precision and ease of setup.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763