What is a Machining Center: A Comprehensive Guide

Many manufacturers face challenges with achieving both efficiency and precision in their production processes. Machining centers, powered by advanced CNC technology, provide a solution by automating complex machining operations, significantly improving both productivity and accuracy.

A machining center is a versatile CNC machine that can perform various tasks such as milling, drilling, boring, and tapping. It is capable of automatically changing tools without needing to reposition the workpiece, which greatly enhances both productivity and precision.

Now that we've covered the basics, let's explore the different types, key components, and practical applications of machining centers, allowing us to gain a deeper understanding and make the most of this advanced equipment.

I.What is a Machining Center?

A machining center is a versatile CNC (Computer Numerical Control) machine tool capable of performing various operations such as milling, drilling, boring, tapping, and more, with minimal human intervention. Unlike traditional machines, machining centers can automatically change tools, process workpieces in a single setup, and perform complex machining tasks. This greatly enhances production efficiency and precision, making machining centers invaluable in industries like aerospace, automotive, and medical equipment manufacturing.

II.The History of Machining Centers

-1950s: The foundation of CNC technology was laid, leading to the development of machining centers.

-1960s: Kearney & Trecker invented the first machining center in the U.S., revolutionizing the manufacturing process.

-1970s: The introduction of automatic tool change systems significantly boosted efficiency.

-1980s: Computer technology advancements made CNC systems smarter and more reliable.

-1990s: The rise of multi-axis machining centers enabled the processing of more complex parts.

-21st Century: The continued evolution led to the introduction of five-axis and composite machining centers, allowing for even greater flexibility and precision.

III.Components of a Machining Center

A machining center consists of several integral components that work together to ensure efficient operation:

Machine Bed: Provides mechanical support and stability for the machine’s components.

CNC System: Controls operations through software and interprets commands for precise movement.

Tool Magazine: Stores tools and facilitates automatic tool changes.

Tool Changer: Automatically swaps tools during operations to save time.

Spindle System: Powers the cutting tools for precise machining.

Servo Motors and Drives: Ensure accurate and smooth movement across axes.

Cooling System: Maintains temperature during cutting to ensure consistent performance.

Chip Conveyor: Helps remove waste material and keep the workspace clean.

Control Panel: Allows operators to input machining programs and adjust machine settings.

IV.Machining Center Basic Process

A machining center can perform the following processes:

Milling: Using a spinning cutter to remove material and shape parts.

Drilling: Creating round holes in the workpiece.

Boring: Enlarging or improving the accuracy of existing holes.

Tapping: Cutting threads inside holes for screws.

Reaming: Finishing holes to make them smoother and more accurate.

Countersinking: Creating a cone-shaped hole for screw heads to sit flush.

Edge Milling: Removing burrs from part edges for a clean finish.

Engraving: Creating patterns or text on the surface of parts.

V.Types and Prices of Machining Centers

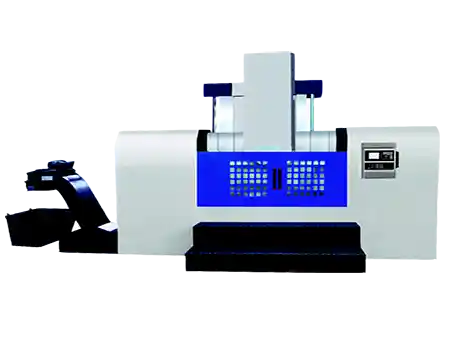

1. Vertical Machining Centers (VMC)

Features: The spindle is vertically oriented, making it ideal for smaller parts and general-purpose machining.

Price Range: $50,000 - $200,000

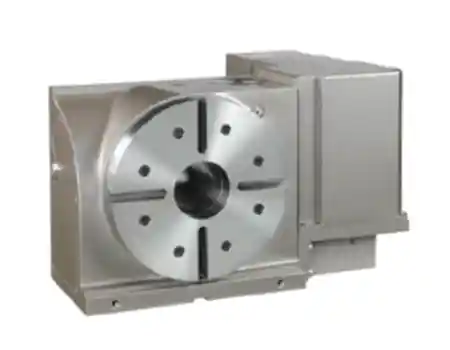

2. Horizontal Machining Centers (HMC)

Features: Spindle orientation is horizontal, enabling efficient machining of large, complex parts.

Price Range: $100,000 - $500,000

3. Gantry Machining Centers

Features: Known for their rigidity and large table size, they are used for heavy and large parts in industries like aerospace.

Price Range: $500,000 - $2,000,000

4. Composite Machining Centers

Features: These centers can perform both turning and milling operations in one setup, ideal for materials like composites and complex geometries.

Price Range: $200,000 - $800,000

VI.Advantages and Disadvantages of Machining Centers

Advantages:

High Precision: Achieves high accuracy, suitable for intricate and detailed parts.

Increased Productivity: Automation and tool-changing capabilities reduce downtime.

Versatility: Performs multiple operations like milling, drilling, and tapping in a single setup.

Consistency: CNC controls ensure repeatable results with minimal human error.

Reduced Labor Costs: Automation decreases the need for manual intervention.

Disadvantages:

High Initial Cost: The upfront cost for machining centers can be substantial.

Complex Maintenance: Requires skilled technicians for regular maintenance.

Training Requirements: Operators need extensive training for efficient handling.

Space Requirements: Larger models require significant floor space.

VII.Spindle Types in Machining Centers

X-Axis: Left and right movements.

Y-Axis: Front and back movements.

Z-Axis: Vertical movement (up and down).

B-Axis: Table or tool rotation for enhanced machining capabilities.

C-Axis: Spindle rotation for complex surface machining.

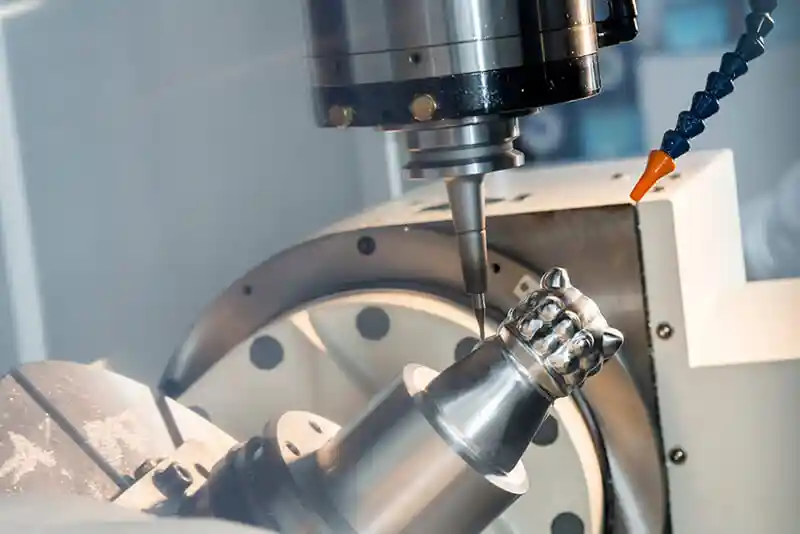

VIII.Axis Configurations and Costs

3-Axis Machining Centers: Standard models with X, Y, and Z axes. Price range: $50,000 - $150,000

4-Axis Machining Centers: Adds a rotating axis for more complex operations. Price range: $150,000 - $300,000

5-Axis Machining Centers: Offers complete 3D machining capabilities. Price range: $300,000 and above.

IX.Major Applications of Machining Centers

Aerospace: For creating precise and reliable parts such as aircraft engines and structural components.

Automotive: Used for making high-precision parts like engine blocks and transmission systems.

Mold Making: Essential in creating molds for plastic, metal, and die-casting.

Electronics: Producing accurate components like phone cases, laptop shells, and more.

X.Factors Affecting Machining Center Prices

Several factors contribute to the pricing of machining centers:

Brand: Renowned brands tend to be more expensive due to better quality and after-sales service.

Model and Configuration: High-performance machines with more axes or composite features cost more.

Precision and Speed: Faster and more accurate machines demand higher prices.

Automation: Machines with advanced automation capabilities are priced higher.

After-sales Service: Comprehensive service and training increase the overall cost.

XI.CNC vs. Machining Centers

While both CNC machines and machining centers are designed for precision manufacturing, machining centers offer more advanced capabilities. A machining center integrates automatic tool changes and can perform multiple processes like milling, drilling, and tapping in one setup. This results in higher efficiency compared to traditional CNC machines.

XII.Differences Between Machining Centers and Turning Centers

Machining centers are primarily used for multi-sided machining of complex parts, while turning centers are designed specifically for rotating parts such as shafts. Machining centers are more versatile, handling a variety of operations in one setup, whereas turning centers are used mainly for cylindrical parts.

XIII.How to Choose a Machining Center

When selecting a machining center, consider the following factors:

Machining Requirements: Choose based on the size and complexity of your parts.

Budget: Select the best machine within your budget.

Brand Reputation: Opt for brands known for quality and reliable customer service.

After-sales Service: Ensure that the brand offers support and training.

Machine Performance: Evaluate the machine's speed, tool magazine capacity, and machining envelope.

XIV.Programming and Controlling a Machining Center

Machining centers rely on CNC programming languages like G-code to function. Operators input the machining program into the CNC system, which then controls the tool paths and parameters for efficient machining.

Conclusion

Machining centers are essential in today’s high-precision manufacturing processes. With advancements in technology, they continue to provide manufacturers with unparalleled efficiency, versatility, and precision. Whether you're in aerospace, automotive, or mold-making, investing in the right machining center can drastically improve your production process.

For more information on machining centers, please visit our website or contact our team of experts.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763