What is the Difference Between the "Regular T-type" and "Inverted T-type" of Horizontal Machining Centers?

Have you ever been confused by the terms "Regular T-type" and "Inverted T-type" when choosing a horizontal machining center? The structural differences between these two types directly affect the machine's cutting performance, suitability for various applications, and even the long-term operational costs.

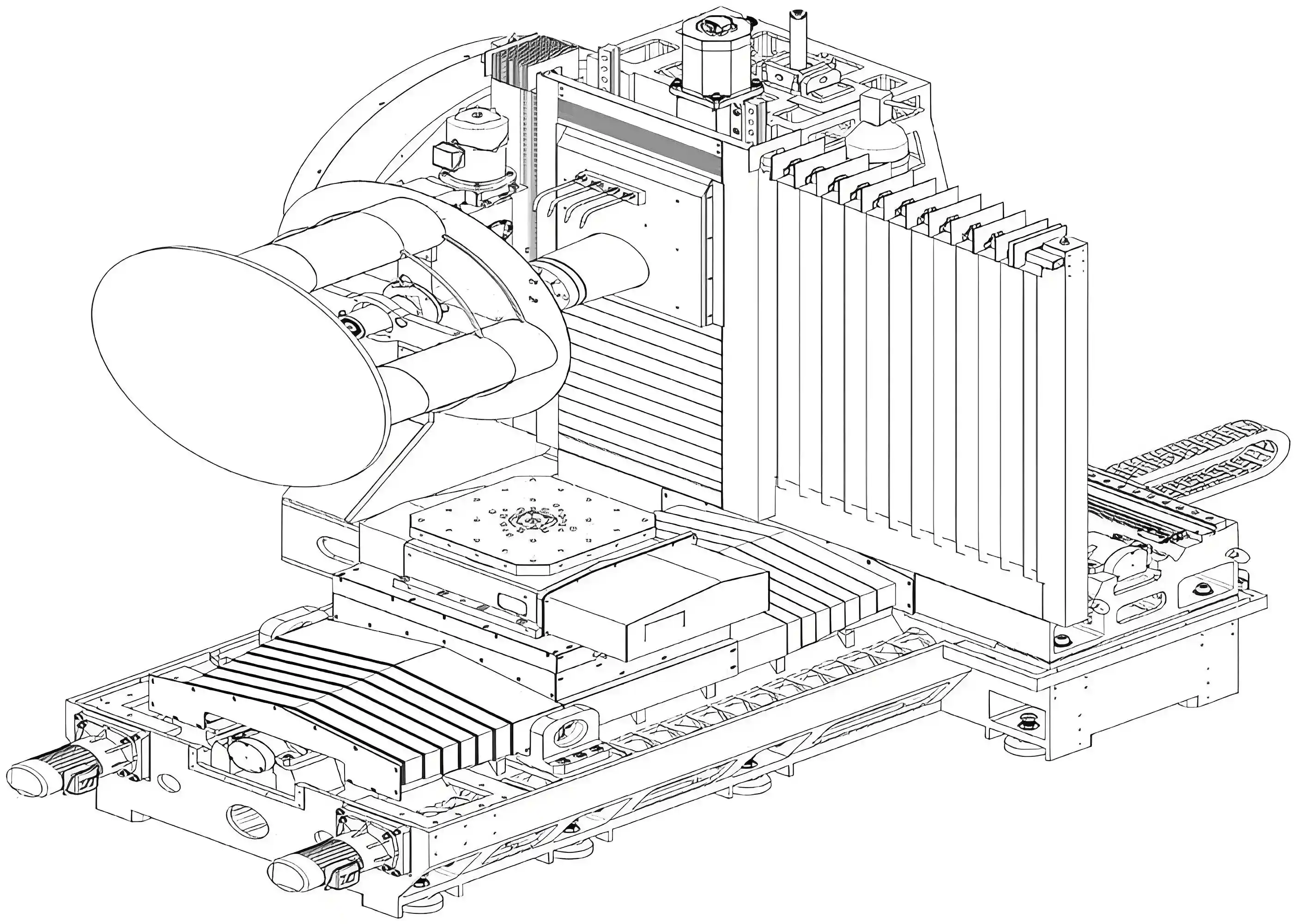

In a Regular T-type structure, the worktable is positioned above the guide rails, offering strong rigidity suitable for heavy-duty cutting. In contrast, the Inverted T-type structure has the worktable embedded between the guide rails, providing a compact design with faster dynamic response, ideal for high-precision and high-speed machining.

Next, let’s take a deeper look into these differences and help you make a better decision that aligns with your needs.

1. Definition: Understanding the “T” Shape from the Layout

To distinguish between the Regular T-type and Inverted T-type, let’s start by understanding their basic structural layouts.

Regular T-type Structure

The key feature is that the worktable and the bed rails are arranged in a “T” shape, with the worktable positioned above the bed rails. From the side view, the bed acts as the main load-bearing component, with the primary guide rails extending horizontally. The worktable is mounted on these rails via components like the saddle, forming a cross shape with the rails.

The key feature is that the worktable and the bed rails are arranged in a “T” shape, with the worktable positioned above the bed rails. From the side view, the bed acts as the main load-bearing component, with the primary guide rails extending horizontally. The worktable is mounted on these rails via components like the saddle, forming a cross shape with the rails.

Inverted T-type Structure

The Inverted T-type structure is essentially a flipped version: the bed rails are laid out in a "T" shape, and the worktable is located below or inside these rails. To put it simply, in the Regular T-type, the worktable is on top of the rails, while in the Inverted T-type, the worktable is nestled between them.

2. Structural Composition:

After understanding the basic definitions, let’s delve into the specific differences in the core components of each structure.

Bed Layout

Structure Type | Regular T-type | Inverted T-type |

Guide Rail Integration | The main and auxiliary rails are often separate and bolted onto the bed. | The guide rails and bed are more likely to be cast as one piece, often forming a “concave” or “convex” shape. |

Support Method | The bed base typically has a flat support design with a grid pattern of reinforcement ribs. | The bed adopts a multi-point support design with reinforcement ribs arranged along the force direction. |

Guide Rail Configuration

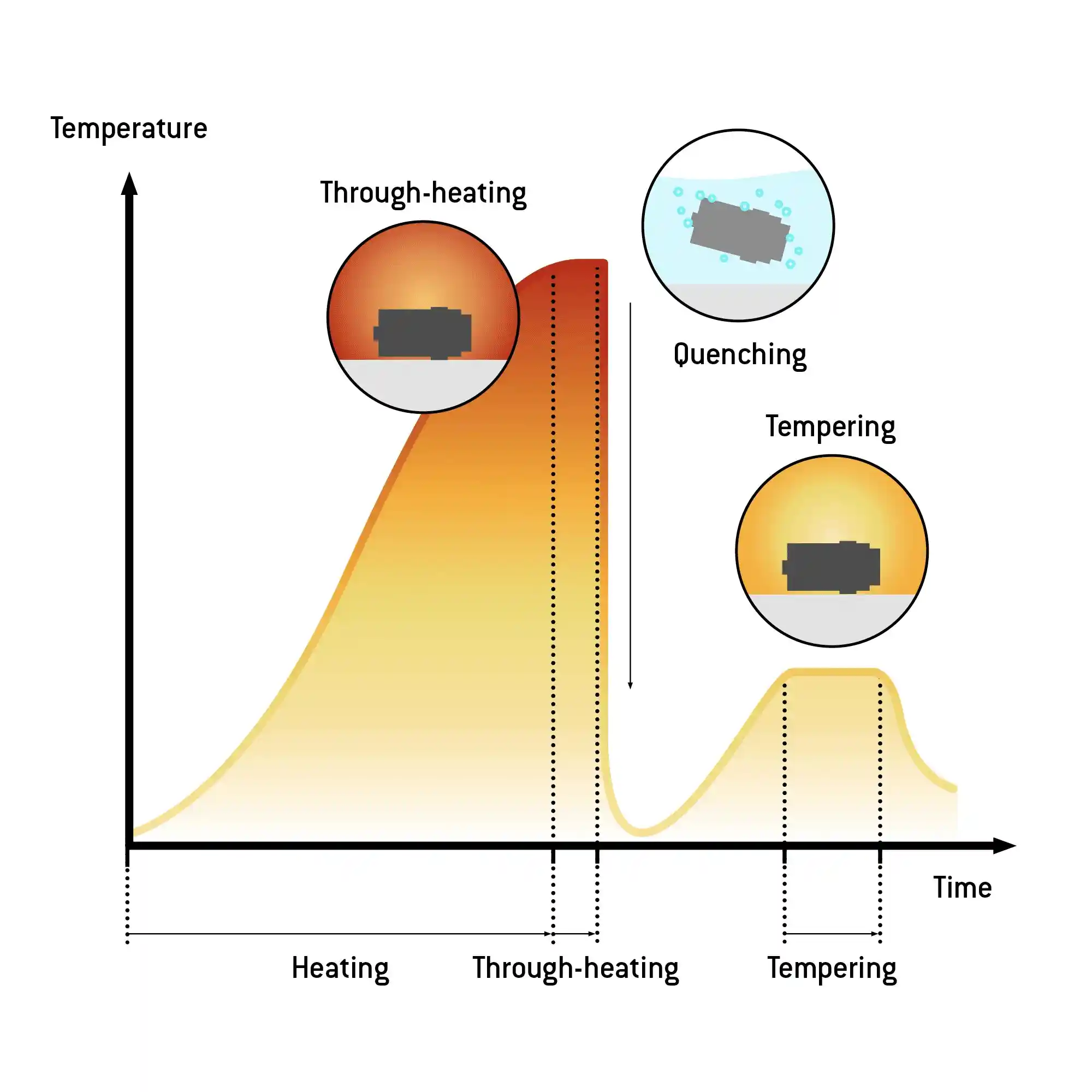

Regular T-type typically uses rectangular or combined rolling guide rails, with 2-3 rails spaced further apart to enhance stability. On the other hand, the Inverted T-type often utilizes high-precision linear rolling guide rails, with hardened surfaces (such as through quenching and grinding), and the connection with the bed uses an interference fit to minimize gaps.

Regular T-type typically uses rectangular or combined rolling guide rails, with 2-3 rails spaced further apart to enhance stability. On the other hand, the Inverted T-type often utilizes high-precision linear rolling guide rails, with hardened surfaces (such as through quenching and grinding), and the connection with the bed uses an interference fit to minimize gaps.

Spindle and Worktable Relative Position

In the Regular T-type, the spindle’s center height is relatively higher, and the worktable’s movement along the X and Z axes is directly limited by the rail lengths. In the Inverted T-type, the spindle is positioned closer to the bed's reference surface, and the rail layout makes the design of the worktable’s travel more flexible, especially in controlling movement precision along the Y-axis.

Column and Worktable Motion Direction

Regular T-type:

Column motion: The column, which holds the spindle, moves along the X-axis (left and right).

Worktable motion: The worktable, holding the workpiece, moves along the Z-axis (front and back).

Inverted T-type:

Column motion: The column moves along the Z-axis (front and back).

Worktable motion: The worktable moves along the X-axis (left and right).

3. Working Principle:

The structural differences directly affect the machine's working principles. Let’s break down how power transmission and load-bearing are handled in each design.

Motion Transmission Path

In the Regular T-type, the power from the servo motor is transmitted to the worktable via a ball screw, passing through intermediate components like the saddle, resulting in a longer transmission chain. The Inverted T-type has a more compact design, with the ball screw directly connected to the worktable, shortening the transmission distance by approximately 15%-20%, leading to faster response times.

Load-bearing Method

In the Regular T-type, the bed's top guide rails bear the load, and cutting forces are distributed through the worktable → guide rails → bed path, with stress concentrated where the rails meet the bed. In the Inverted T-type, the load is shared by the guide rails on both sides of the bed, with cutting forces transmitted directly to the bed’s base, providing a more uniform stress distribution.

Force Balancing Mechanism

Both structures must balance the effects of gravity on motion. The Regular T-type often uses counterweights to offset the worktable's weight, while the Inverted T-type employs a symmetrical rail design and hydraulic balancing systems to reduce the shift of the center of gravity during motion.

4. Performance Comparison:

The differences in structure and principles ultimately reflect on the machine's actual performance. Let’s compare several key performance indicators.

Rigidity and Stability

Regular T-type: Exhibits greater stability in heavy-duty cutting (cutting force> 5000N), with static rigidity reaching 20-30N/μm. However, it is prone to precision fluctuation due to vibration during high-speed cutting.

Inverted T-type: Shows superior dynamic rigidity during high-speed cutting (spindle speed > 8000 rpm), with vibration levels 20%-30% lower than the Regular T-type, but may experience more deformation under heavy loads.

Processing Accuracy

Accuracy Indicator | Regular T-type | Inverted T-type |

Positioning Accuracy | ±0.005-0.01mm/300mm | ±0.003-0.008mm/300mm |

Repetition Accuracy | ±0.003-0.005mm | ±0.002-0.004mm |

Thermal Error Impact | More affected by thermal deformation, requiring regular calibration | Better thermal error compensation design, maintaining accuracy for longer periods |

Dynamic Response

The worktable of the Inverted T-type has a smaller inertia, reducing acceleration time by about 10%-15% compared to the Regular T-type, with a maximum feed rate of 60-80m/min. The Regular T-type, with its more stable structure, is better at resisting disturbances from sudden load changes, such as variations in cutting material hardness.

5. Application Scenarios: Which Structure Suits Your Needs?

After understanding the performance differences, let’s see which structure suits various machining scenarios.

Heavy-duty Cutting

The Regular T-type is better suited for large workpieces such as machine frames and large boxes (workpiece weight > 500kg), as its bed rigidity ensures stability during continuous cutting. The Inverted T-type performs well in medium-load (200-500kg) cutting but may experience accelerated guide rail wear under heavy-duty conditions.

Precision Machining

(optical scale)

The Inverted T-type is more suitable for high-precision parts such as mold cores and precision gears, especially for applications requiring surface roughness Ra < 0.8μm. The Regular T-type can also meet precision machining needs with the addition of optical scales, but the calibration cost is higher upfront.

Production Mode Adaptation

Mass Production: The Regular T-type offers better integration for automated loading and unloading, ideal for large-scale manufacturing of auto parts.

Small Batch and Multi-Variety: The Inverted T-type offers more flexible worktable adjustments, reducing setup time by 20%-30% compared to the Regular T-type.

6. Design and Usage: Costs and Maintenance

When selecting, it’s essential to consider practical details like costs and maintenance.

Manufacturing Cost

The Regular T-type is simpler to cast and costs 10%-15% less than the Inverted T-type. The Inverted T-type, with its high-precision guide rail processing and integrated bed design, requires a higher initial investment but has lower long-term operational costs.

Maintenance Convenience

Regular T-type: The guide rails tend to accumulate debris and need to be cleaned weekly. The ball screw lubrication points are concentrated, requiring frequent maintenance.

Inverted T-type: The sealed design is more effective at protecting the guide rails, extending the maintenance interval to once a month.

7. Conclusion

The core differences between these two structures are as follows:

Regular T-type: Best for heavy-load stability and cost-effectiveness.

Inverted T-type: Best for high-precision and flexible response.

If you still have questions about specific scenarios, feel free to reach out to Minnuo. As a professional machine tool manufacturer specializing in solution-based products, we’re here to provide expert advice and help you choose the best machining solution to meet your needs.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763