CNC Milling / Turning/ Metal Folding: One-stop CNC Machining service to meet customized needs

In the industrial manufacturing sector, customization is evolving from a niche need to a mainstream option. From precision connectors for electronic devices to support structures for new energy vehicles, companies need to customize metal parts based on product characteristics. However, under traditional processing models, companies must connect with CNC milling plants, lathe plants, and metal folding plants separately. This not only increases communication costs but also often leads to delays and precision deviations due to process integration issues.

A one-stop CNC Machining service combining CNC milling, turning, and metal folding can effectively address these pain points through "multi-process integration and full-process control." This article, drawing on actual production cases, analyzes the application scenarios of the three major processes, deconstructs the core advantages of one-stop services, and shares practical tips for companies to select service providers, helping you efficiently implement customized processing needs.

I. Three core processes: How to divide the work in actual production?

The key to one-stop service is to ensure that the three processes "perform their respective functions and work in synergy." Different processes are targeted at different part structures. Only by clarifying their applicable scenarios can we accurately match customized needs.

1. CNC milling: the "fine engraver" of complex parts

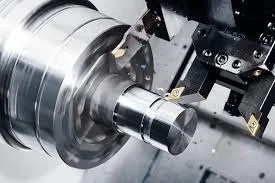

CNC milling uses a rotating milling cutter to cut the workpiece, and can process complex structures such as planes, grooves, and curved surfaces. It is the "core process" of customized parts.

A practical application example: A medical device manufacturer needed to customize a batch of aluminum alloy surgical forceps housings with curved grooves and precise positioning holes. Traditional machining made it difficult to ensure consistency. Using CNC milling, CAD drawings were imported into the CNC system, and the milling cutter cut along a preset path. The final product achieved an accuracy of ±0.008mm, increasing the pass rate from 85% to 99%.

Applicable scenarios: Aerospace parts (such as turbine blades), automotive molds (such as instrument panel injection molds), precision instrument housings, and other products that require multi-dimensional cutting.

Material adaptation: common metals such as aluminum alloy, stainless steel, titanium alloy, brass, etc., especially suitable for customized parts with high hardness and complex structure.

2. CNC turning: an efficient production line for rotating parts

CNC turning is based on workpiece rotation, with the tool moving along the axis. It is primarily used for "rotationally symmetrical" parts such as shafts and discs, and is a key efficiency driver for customized mass production.

A practical application example: A motor manufacturer ordered 1,000 custom motor shafts, requiring a shaft diameter error of no more than ±0.01mm and a smooth, burr-free surface. Traditional lathes required manual tool adjustment, and processing each shaft took 15 minutes. However, with CNC turning, automatic feeding and continuous cutting, this time was reduced to 5 minutes per shaft. Furthermore, thanks to real-time monitoring by the CNC system, the shaft diameter error was consistently controlled within ±0.005mm.

Applicable scenarios: Standardized or customized rotating parts such as motor shafts, bolts and nuts, hydraulic joints, and bearing sleeves.

Core advantages: Processing efficiency is 30%-50% higher than traditional lathes, supports 24-hour continuous production, and is suitable for small and medium-sized batches (50-5000 pieces) of customized needs.

3. Metal Folding: The Form Shaper of Sheet Metal Structures

Metal folding uses hydraulic or mechanical pressure to bend metal sheets at a preset angle to form a three-dimensional structure. It is often combined with milling and turning to complete the customization of "integrated parts".

A practical application case: A certain equipment manufacturer customized a batch of stainless steel chassis. The chassis needed to include right-angled edges, curved transition structures, and no welding marks. After using metal folding processing, positioning holes were first processed in the plate through CNC milling, and then a CNC folding machine was used to bend according to the drawing. The final product did not require welding, the structural strength was increased by 20%, and the appearance was also smoother.

Applicable scenarios: Equipment housing, chassis cabinets, bracket frames, guardrails and other sheet metal custom products.

Parameter range: supports metal sheets with a thickness of 0.5mm-20mm, with a folding angle accuracy of ±0.5°, which can meet different appearance and structural requirements.

II. The actual value of one-stop service: What pain points does it help companies solve?

For most manufacturing companies, the core demands of customized machining are "cost reduction, efficiency improvement, and quality assurance." One-stop CNC Machining services directly address these practical pain points through integrated processes.

1. Shorten construction time: Avoid losses caused by multiple vendors’ connection

Under the traditional model, companies must first find a milling factory to process the main body of the part, then send it to a lathe factory to process the shaft structure, and finally find a folding factory to make the shell. Each link requires separate communication and progress confirmation, and dimensional deviations in the previous process may lead to rework in the subsequent process.

Take the customization of a set of industrial equipment brackets as an example:

Traditional mode: milling (3 days) + turning (2 days) + folding (2 days) + connection and waiting (3 days), the total construction period is about 10 days;

One-stop service: The three major processes are completed within the same manufacturer, eliminating the need to wait for process connections. The total construction period can be shortened to 5-6 days, increasing efficiency by more than 40%.

2. Reduce costs: reduce waste in intermediate links

When working with multiple manufacturers, each stage requires separate transportation and quality inspection, and inconsistent process standards can lead to scrapped parts. One-stop service can effectively reduce this waste:

Transportation costs: Parts do not need to be shipped between different manufacturers. For example, for a 100kg part, the cost of shipping between manufacturers is approximately 200-500 yuan per shipment. One-stop service can completely save this cost.

Quality inspection costs: Using unified quality inspection standards (e.g., full inspection with a three-coordinate measuring machine) across the same manufacturer avoids repeated quality inspections across multiple manufacturers, reducing quality inspection costs by 30%;

Scrap cost: With smooth process integration, the scrap rate of parts has been reduced from 8%-10% in the traditional model to 2%-3% in the one-stop service model.

3. Quality assurance: Unified standards to reduce errors

Customized parts often require multiple processes to coordinate, such as "the milled hole position needs to be precisely aligned with the turned shaft diameter." If they come from different manufacturers, differences in equipment accuracy and measuring tools may lead to matching errors.

An auto parts manufacturer once encountered a problem: a "milled flange" and a "turned sleeve" processed by different manufacturers were found to have difficulty fitting into the flange hole during assembly. After investigation, it was discovered that the two manufacturers had inconsistent dimensional standards (one factory converted in millimeters, the other in inches).

The one-stop service uses unified design standards, measurement tools, and quality inspection processes to effectively avoid such problems. The matching error can be controlled within ±0.01mm, meeting the needs of precision assembly.

III. How to choose a reliable one-stop service provider? 4 practical criteria

There are many CNC machining service providers on the market, and not all of them offer a truly one-stop service. Companies can avoid pitfalls by screening based on the following four practical dimensions:

1. Check process coverage: confirm whether it is a "true full process"

Some service providers claim to be "one-stop" but in reality only offer milling and turning services. Metal folding must be outsourced, which can still lead to connection issues. Things to keep in mind when selecting:

(Minnuo 5 Axis Machining Center)

Requires a "list of three major process equipment", such as CNC milling machines (whether they support five-axis linkage), CNC lathes (whether they have inclined beds), and metal folding machines (whether they have CNC positioning).

Ask "Are there any cases of fully self-processing?" For example, if a product is completed in-house from milling to folding, you can ask to see a production video or finished product sample.

2. Industry experience: Prioritize providers in the same field

Customization requirements vary greatly across industries. For example, medical devices must comply with ISO 13485, while automotive parts must meet IATF 16949. We prioritize service providers with experience in the same industry:

For example, if you are making new energy vehicle parts, you can ask, "Have you customized brackets/connectors for car manufacturers?"; if you are making precision instruments, you can ask, "Have you processed parts with an accuracy of ±0.005mm?"

Check the service provider's "industry qualification certificates", such as ISO 9001 (basic quality), ISO 13485 (medical), etc., to ensure compliance.

3. Small-batch adaptation: Can it meet the "trial production requirements"?

Many companies need to conduct a small trial run (e.g., 10-50 pieces) before ordering custom parts to verify the feasibility of the design. The service provider should be:

Does it support "small batch customization"? What is the minimum order quantity (MOQ)? Is there any additional price surcharge?

How long is the trial production cycle? Can the process be adjusted? For example, if there is a dimensional deviation of trial production parts, can the program be optimized quickly?

4. Check after-sales service: Can problems be resolved promptly?

Customized processing inevitably leads to minor problems, such as dimensional deviation and surface defects. Reliable service providers will provide after-sales protection:

Ask "How are quality issues handled?", such as whether defective parts can be reworked free of charge and how long the rework cycle is;

Understand the "after-sales response speed", such as whether a solution is provided within 24 hours after receiving feedback on the problem.

IV. Conclusion: Make customized processing more worry-free

For manufacturing companies, one-stop CNC Machining services offer more than just multi-process integration; they offer a cost-saving and efficiency-enhancing solution. From precision milling of complex parts to efficient turning of rotary parts and precise folding of sheet metal structures, comprehensive process control allows for smoother implementation of customized requirements.

When choosing a service provider, don't blindly pursue scale. Instead, prioritize partners with compatible processes, industry-specific capabilities, and reliable after-sales service. If you're facing customized processing needs, first clarify your core requirements (such as precision, deadlines, and materials), then filter by these criteria. You'll likely find the right service provider, making customized production more efficient and worry-free.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763