Regular maintenance

185mm X-Axis Travel · 350mm Z-Axis Travel · 300mm Max. Machining Length

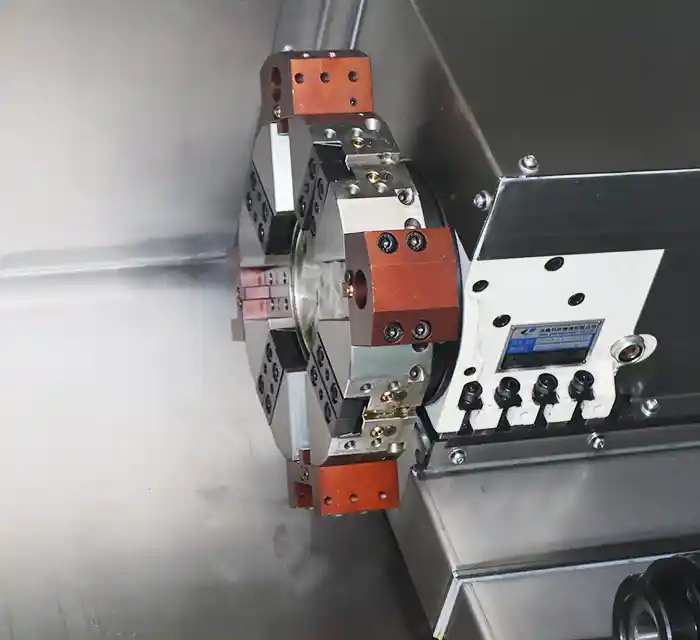

The MNT36A is a high-efficiency slant-bed CNC lathe designed for the precise machining of small components. Its rigid inclined bed structure, combined with precision ground ball screws, ensures stable performance and fine surface finishes. This machine is ideal for producing complex small-to-medium parts across industries that demand consistency and tight tolerances.

MNT Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Slant-Bed Construction The inclined ribbed bed maximizes chip removal efficiency while enhancing structural rigidity.

- ● High-Precision Ball Screws Enable smooth feed motion and accurate positioning in X and Z axes.

- ● Compact Machining Capability Ideal for short-length parts up to 300mm, with fast cycle times.

- ● Stable Cutting Platform Reduced vibration and thermal distortion improve long-term precision.

- ● User-Friendly Interface Supports integration with multiple CNC control systems for ease of use and automation.

Recommended Configurations

- ● Spindle: High-precision spindle with cooling system, servo spindle drive

- ● Drive System: Servo motor, linear motor drive (high precision, high speed)

- ● Automation: Automatic tool changer (ATC), automatic loading/unloading system, robot arm integration

- ● Cooling System: High-pressure cooling system, built-in cooling system

- ● CNC Control System: High-performance CNC system (FANUC, Siemens, etc.), optimized human-machine interface

- ● Measuring and Monitoring: Tool breakage detection system, online measurement system, vibration monitoring system

- ● Other Configurations: Hydraulic/pneumatic chucks, rotary turret/tool magazine system, protective cover design

Application Case

- ● Client: Electronics Components Supplier – South Korea

- ● Use Case: High-volume turning of threaded copper connectors

- ● Setup: MNT36A with automatic parts catcher and bar feeder

- ● Results: • Dimensional repeatability within ±0.01 mm • Part cycle time reduced by 22% • Surface finish maintained at Ra ≤ 1.6 μm

- ● Client Feedback: “The TCK36A gives us the performance we need to meet strict precision demands at scale.”

Product Specifications

| Specifications | unit | MNT25Y | MNT50A | MNT46A | MNT50A | MNT50M | MNT50Y |

|---|---|---|---|---|---|---|---|

| Max.swing dia.over bed | mm | 510 | 360 | 460 | 560 | 560 | 640 |

| Max.swing dia.over slide | mm | 150 | 140 | 260 | 300 | 300 | 380 |

| Max.work piece length | mm | 235 | 300 | 350 | 300/550/800/1500 | 400/700/1500 | 400/700/1500 |

| Max.bar capacity | mm | 44 | 38/44 | 44 | 55/75 | 55/75 | 55/75 |

| Max.processing diameter(plate) | mm | 250 | 360 | 440/360 | 440/360 | 300/350 | 300/450/450 |

| Spindle nose | GB59001 | A2-5 | A2-5 | A2-5 | A2-6/8 | A2-6/8 | A2-6/8 |

| spindle bore | φ/mm | 56 | 48/56 | 56 | 66/66/86 | 66/86/86 | 66/86/86 |

| Spindle speed | r/min | 50-4500 | 50-4000 | 50-3500 | 50-3000 | 50-3000 | 50-3000 |

| Spindle shift mode | / | stepless speed control | |||||

| Spindle motor power | KW | 7.5/5.5 | 5.5 | 7.5 | 11/11/15 | 11/15/15 | 11/15/15 |

| Chuck type | / | Hydraulic chucks | |||||

| Chuck size | Inch | 6 | 6 | 8 | 10 | 10 | 10 |

| Xaxisrapid traverse | m/min | BW70-Y-35- BMT40-12T-4L | 24 | 24 | 24 | SHD16L/TCSD80-12T-330 | TCSDY80H-12T-330 |

| Zaxis rapid traverse | m/min | 24 | 24 | 24 | 24 | 18 | 18 |

| Xaxisservo motor torque | N.m | 24 | 6 | 7.5 | 10/15 | 18 | 18 |

| Zaxis servo motor torque | N.m | 10 | 6 | 7.5 | 10/15 | 15 | 15 |

| Xaxi travel | mm | 10 | 185 | 240 | 240 | 15 | 15 |

| Zaxis travel | mm | 135 | 350 | 400 | 400/540/860/1560 | 240/260/260 | 240/260/260 |

| Guide way type | / | ±30 | Linear guides | Linear guides | Linear guides | / | ±45 |

| turret type | / | 370 | Horizontal 8/12 stations | 500/800/1500 | 500/800/1500 | ||

| tool shank size | mm | rails | 20X20/025 | 25×25/032 | 25X25/032 | rails | rails |

| Tail stock type | / | BMT40 | Hydraulically | Hydraulically | Hydraulically | BMT45 | BMT45 |

| Tail tock qull dia | φ/mm | 20X20/025 | 65 | 70 | 70/90 | 25X25/032 | 25X25/032 |

| Tail stock quiltravel | mm | / | 60 | 80 | 80 | Hydraulically | Hydraulically |

| Tail stock quilltaper | / | / | MT4# | MT5# | MT5# | 70/90 | 70/90 |

| Total rated power | KW | 9 | 11 | 14/18/22 | 80 | 80 | |

| Totalrated current | A | 18 | 19 | 23 | 30 | 24 | 24 |

| Net weight | kg | 2500 | 2500 | 3000 | 3100/3300/4000/5000 | 3300/4000/5000 | 3400/4100/5100 |

| Machine dimension (LxW×H) | (mm) | 1810×1480×1940 | 2200×1636×1850 | 2500×1950×1950 | 2600/2700/3300/4000X2000X2000 | 2600/3370/4100×2000×2000 | 2600/3370/4100×2000×2100 |

Catalog

Frequently Asked Questions

Of course ,our 5 axis cnc slant bed lathe can perform more complex machining tasks.

The servo system uses products from Siemens (or you can specify the brand), and the ball screws are from THK. This ensures the high quality and reliability of the CNC machine tool.

As a professional slant bed cnc lathe machine manufactor, Minnuo offers direct factory sales. We will provide the most suitable quotation according to customers' requirements to ensure the highest cost - performance ratio.

Minnuo's pre - sales team responds quickly. For a single CNC lathe machine, we'll give equipment recommendations within 10 minutes upon getting the drawings. For a production line of multiple CNC machine lathes, a solution will be provided within 5 working days.

We have complete basic production equipment. For CNC lathe machines, we customize components like machine systems, spindle speeds, motor power, and outer shell sheet metal.

Our top - brand processing machines ensure part machining accuracy in CNC slant bed lathe. We provide quality inspection reports for CNC machine lathes at factory - leaving.

We stock standard CNC slant bed lathe for quick delivery. Custom CNC machine lathes are delivered in 30 - 45 working days.

Our slant bed cnc lathe machines have a one - year warranty with free repairs. Contact our 24/7 after - sales team for malfunctions. Issues are resolved via remote video, phone, or on - site service.

A slant bed CNC lathe offers advantages such as better chip evacuation, higher rigidity, improved accuracy, and easier operator access compared to a flatbed lathe.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763