Regular maintenance

Horizontal Table: 850×450mm · Vertical Table: 1190×250mm · X/Y/Z Travel: 600 / 450 / 450mm

The XL8132/40/45 Series Universal Tool Milling Machine features vertical and horizontal heads with dual worktables for flexible multi-angle machining. With a wide speed range, gear-driven transmission, and optional CNC upgrade, it offers powerful cutting and precise control in a compact, rigid design.

XL8132/40/45 Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Dual Milling Head Configuration: Supports both vertical and horizontal milling for multi-functional, flexible machining setups.

- ● Dual Worktable Layout: Separate vertical and horizontal tables enhance workholding options and operational efficiency.

- ● Wide Gear Speed Range: Gear-driven spindle with stepless 2-stage adjustment and 40–2000 rpm output for various materials.

- ● Electronic Handwheel Feed: Three-axis handwheel control enables accurate, responsive positioning for manual operations.

- ● CNC Upgrade Capability: Optional CNC system available for users seeking a semi-automated or fully automated workflow.

Recommended Configurations

- ● Spindle System: Adjustable speed spindle

- ● Worktable: T-slot worktable, ±45° rotating worktable, coordinate system,Rotary table

- ● Feed System: Manual feed system, electric feed adjustment

- ● Cooling and Lubrication System: Coolant spray device,Automatic centralized oil lubrication

- ● Clamping System: Standard fixtures, quick-change fixture device

- ● Precision Guideways: Rolling guideways or sliding guideways

- ● Other (Safety Protection System): 45° high-speed rotating tool turret, digital readout, dividing head, protective covers, emergency stop button and safety lock, LED work lamp,cutting disc

Application Case

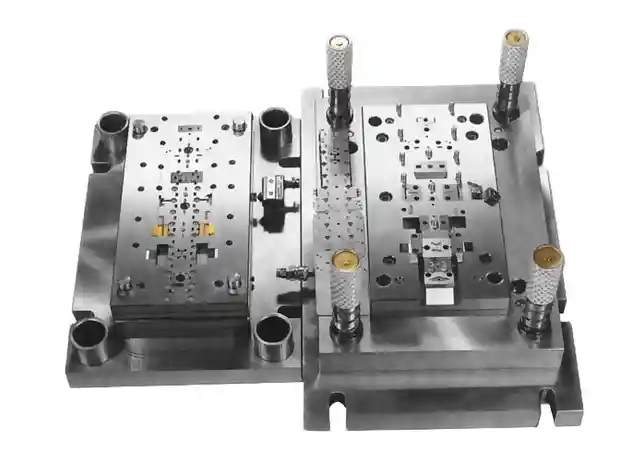

- ● Client: Mold & Fixture Workshop – Brazil

- ● Workpiece: Base plates and mounting brackets for injection molding tools

- ● Setup: XL8132 with DRO, dual-head setup, and rotary table

- ● Results: • Enabled both vertical drilling and horizontal boring in a single setup • Improved workpiece alignment accuracy by 25% with DRO assistance • Reduced handling time by 30% using dual-table configuration

- ● Client Feedback: “This machine exceeded our expectations in flexibility and stability. It’s a cost-effective solution that adapts to our growing production complexity.”

Product Specifications

| Specification | Unit | XL8132 | XL8140 | XL8145 |

|---|---|---|---|---|

| Horizontal table size(L×W) | mm | 750×320 | 800×400 | 850×450 |

| T-slots(Number/width/distance) | mm | 5*14*63 | 6*14*63 | 7*14*63 |

| Vertical table size(L×W) | mm | 890×225 | 1020×225 | 1190×250 |

| T-slots(Number/width/distance) | mm | 3*14*63 | 3*14*63 | 3*14*63 |

| Max.table load | kg | 160 | 200 | 300 |

| X/Y/Z axes travel | mm | 405/305/400 | 500/400/400 | 600/450/450 |

| Spindle taper(H.&V.) | — | NT40 | NT40 | NT40 |

| Spindle speeds(H.&V.,variable) | rpm | 40-2000 | 40-2000 | 40-2000 |

| Stroke of vertical spindle quill | mm | 60 | 60 | 60 |

| Feed rate(X/Y/Z axis) | mm/min | 10-1000 | 10-1000 | 10-1000 |

| Rapid traverse(X/Y/Z axis) | mm/min | 1200 | 1200 | 1200 |

| Main motor power | Kw | 3.7 | 3.7 | 5.5 |

| Feed motor torque(X/Y/Z axis) | Nm | 7.7/7.7/10 | 7.7/7.7/10 | 10/10/15 |

| Machine Weight | kg | 1450 | 1550 | 1750 |

| Machine dimensions(LxWxH) | mm | 1500×1700×1800 | 1500×1700×1800 | 1600×1800×2000 |

Catalog

Frequently Asked Questions

A universal vertical milling machine has a vertically oriented spindle, making it suitable for flat surface machining. A horizontal universal milling machine features a horizontally oriented spindle, ideal for side milling or long workpieces. Some high-end models can switch between vertical and horizontal modes, enhancing versatility.

Compared to a standard vertical milling machine, a universal milling machine typically features a multi-angle adjustable spindle head, a rotating worktable, and greater workpiece adaptability. It supports both vertical and horizontal multi-surface machining, making it ideal for complex structures and small-batch, variable-part production scenarios—such as the Huron universal milling machine.

Absolutely! Minnuo has a strong and responsive pre-sales team. As long as you provide part drawings, whether it's for a single universal milling machine or a production line with multiple machines, we can recommend a solution within 10 minutes. For full-line projects, a complete proposal will be delivered within 5 working days.

We have full production capabilities and can customize the universal milling machine based on your specific needs, including travel range, spindle type, motor power, control system brand, and tool change method. Whether it's a traditional manual model or a CNC universal milling machine, non-standard customization is supported to meet a variety of machining scenarios.

We are equipped with high-end machining centers from top international brands, ensuring the machining precision of all core components of our universal milling machines. Each unit undergoes full machine testing before delivery and includes a quality inspection report to ensure it meets delivery standards.

For standard models, we maintain stock for fast delivery. If you require a customized universal milling machine or a horizontal universal milling machine, the delivery time is typically 30–45 working days, depending on the configuration.

The equipment you purchase comes with a one-year warranty. During the warranty period, you are entitled to free repair services in the event of equipment failure. We also provide remote video guidance, phone-based technical support, and on-site service when needed to help you resume production quickly and minimize downtime.

The universal milling machine price varies depending on the model, configuration (such as whether it's a CNC bed type universal milling machine), travel specifications, and whether customization is required. Minnuo will provide a detailed and transparent formal quotation based on your specific needs, with optional inclusion of taxes and shipping.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763