Flooding in Texas, USA: How to Manage Moisture Protection, Rust Prevention, and Disaster Management for Machine Tools?

In the past few weeks, Texas, USA, has been hit by heavy rainfall, leading to severe flooding in several areas. As of now, at least 78 people have died, dozens are missing, and several industrial parks have been submerged, with equipment shut down and workshops halted. Similar flood events have frequently occurred in Southern China, India, Germany, and other regions, directly impacting the manufacturing sector’s operations and delivery capabilities.

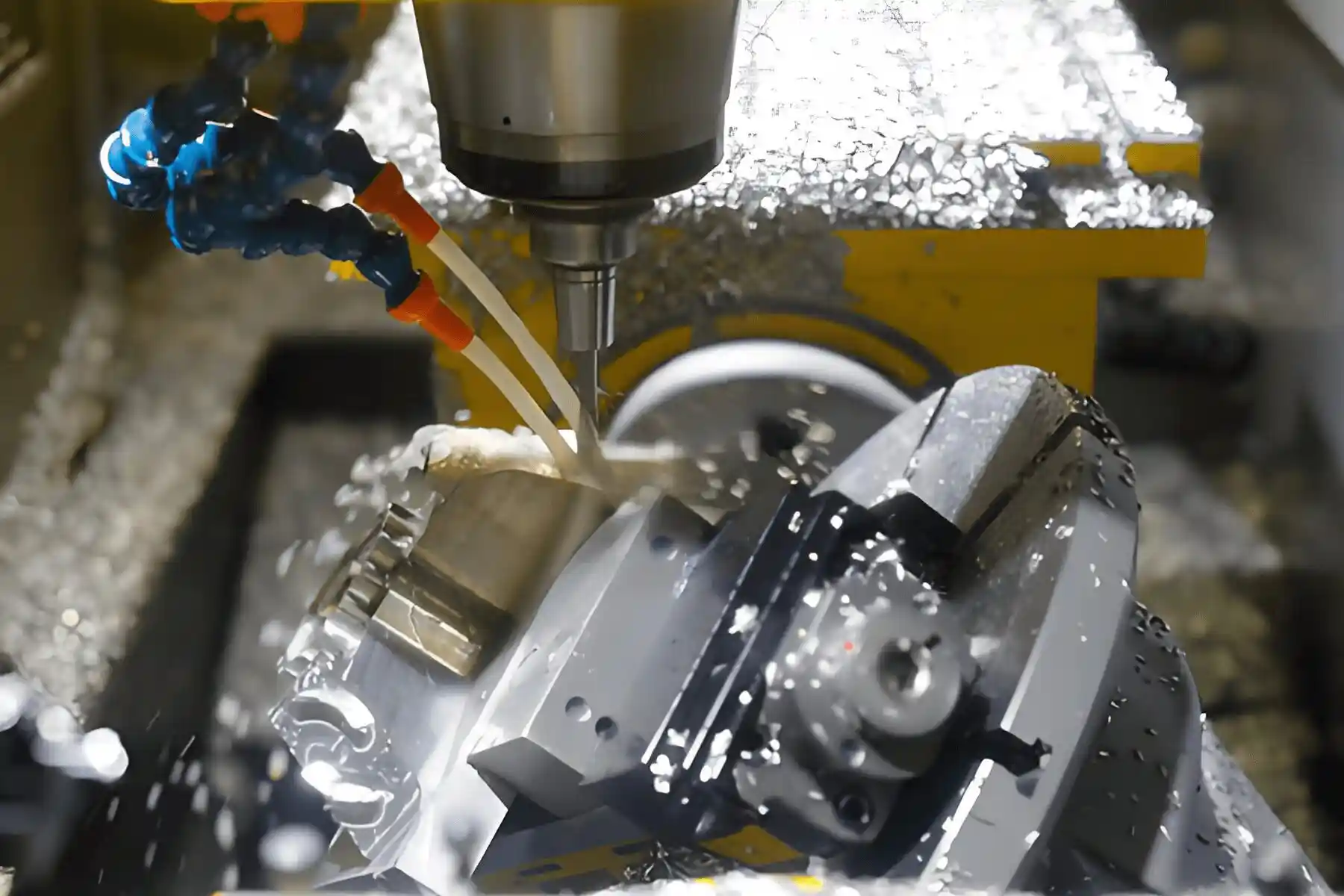

For the machining industry, the impact of flooding goes far beyond short-term downtime. Once water enters the workshop, machine tools are prone to issues such as control system failures, rusting of guides, motor water ingress, and electrical cabinet short circuits. Even if not directly submerged, high humidity and corrosive environments can quickly degrade equipment performance and even cause it to fail completely.

So, how can manufacturing companies improve their equipment’s environmental resilience in the face of increasingly frequent flood threats? This article will provide a set of practical strategies for moisture control, rust prevention, and disaster management for CNC machines.

1. Moisture Control: Moisture is the Largest Hidden Killer of CNC Machines

In rainy, high-humidity environments, the first parts to be affected are often not the structural components but the electrical systems. When moisture enters the electrical cabinet, it can cause circuit board oxidation, drive module short circuits, poor relay contact, leading to abnormal machine alarms or even a complete shutdown.

Recommended Measures:

Control cabinets should have a protection rating of at least IP65 and be equipped with anti-condensation heaters.

Install industrial dehumidifiers and, if possible, maintain the workshop humidity between 40%–60%.

Use humidity sensors linked to the dehumidification system, which can trigger automatic alarms when abnormal humidity is detected.

Use waterproof-sealed terminals for cable interfaces to prevent moisture ingress.

Pro Tip: After work hours, do not immediately close the electrical cabinet; allow the equipment to naturally dissipate heat and remain dry, avoiding "moisture entrapment."

By following these moisture control measures, you can effectively reduce the damage caused by moisture to electronic components, ensuring the continued stable operation of CNC machine tools.

2. Rust Prevention: Rust is Not Just a Cosmetic Issue; It’s a Precision Killer

Even if a machine’s structure is intact and the system is functioning normally, rust on key parts such as guides, ball screws, or spindles can cause significant precision deviation and increased motion resistance, ultimately affecting product quality.

Prevention Methods Include:

Apply anti-rust oil to exposed metal surfaces such as bed rails daily.

For long-term shutdowns, use moisture-proof cloths or vacuum packaging.

Maintain the PH value of the coolantbetween 8.5–9.5 to avoid the accumulation of corrosive liquids.

Prefer machines with corrosion-resistant coatings (such as epoxy spraying, anodizing).

Install micro-lubrication systems (MQL) to reduce exposed oxidation surfaces.

Important Note:

Once rust forms, especially pitting corrosion, it is difficult to repair and can become a long-term issue that impacts the longevity of machine tool guides, leading to permanent damage.

3. Disaster Preparedness: Prevention is Better Than Last-Minute Rescue in the Face of Floods

In recent years, extreme storms have led to urban flooding and industrial park water ingress. Many companies have faced severe losses because they didn’t have proper flood protection planning, leading to submerged equipment, scrapped electrical cabinets, and damaged motors, with losses sometimes reaching hundreds of thousands or even millions of dollars.

Recommended Disaster Prevention Strategies:

Set up drainage channels in the workshop, and ensure that the equipment base is raised (recommended height: at least 30cm).

Install high-level electrical systems to avoid ground-level installations that could be submerged.

Use removable waterproof covers and sealed electrical cabinets to reduce the risk of water ingress.

Equip machines with UPS (uninterruptible power supply) to ensure automatic data saving and orderly shutdown in case of power failure.

Develop an SOP for emergency shutdown and startup, ensuring that personnel can operate in an organized manner during unexpected events.

Many users only realize the importance of prevention after their equipment is damaged by floods, but by then, it is often too late. Disaster preparedness should be implemented in advance to minimize damage.

4. Selection Recommendations: CNC Machine Tool Specifications for Humid and Flood-Prone Areas

Actively considering the "environmental adaptability" of machine tools during the selection process can significantly reduce the failure rate throughout the equipment’s life cycle. For humid environments or flood-prone areas, the following aspects should be reviewed during the technical inspection:

Ensure control cabinets and electrical interfaces meet IP65 or higher protection standards.

Choose machines with corrosion-resistant coatings on the bed, rails (such as epoxy, ceramic, or anodized coatings).

Ensure that motors, ball screws, spindles, and other key components have waterproof-sealed structures.

Equip machines with humidity sensor systems and automatic alarm mechanisms.

Support micro-lubrication and anti-rust lubrication systems to ensure smooth operation in humid environments.

Equip with UPS power protection and data backup interfaces to handle unexpected power failures and disasters.

Machines with the above configurations are the only ones that can truly achieve "adapting to the environment rather than being controlled by it."

5. Why Choose Minnuo CNC Machine Tools?

Minnuo has gained deep insights into the unique environmental needs of markets with high humidity, such as Southeast Asia and Sub-Saharan Africa. Through technical optimization, Minnuo offers users reliable solutions tailored to special climatic conditions.

The Advantages of Minnuo CNC Machines in Humid Environments:

High Protection Electrical System Design

All control cabinets are designed with a modular sealed structure, with an optional IP67protection rating. Key connectors use double-layer waterproof seals, combined with an internal heating system to prevent condensation.

Corrosion-Resistant Structural Components

Major machine metal surfaces are treated with corrosion-resistant coatings, such as epoxy spraying or hard anodizing, to reduce rust risks.

Intelligent Environmental Monitoring

Many Minnuo models are equipped with humidity sensors and alarm logic that can automatically trigger the dehumidification system when environmental conditions go awry, providing proactive shutdown protection.

Customizable "Humid and Heat Environment Package"

Minnuo offers a comprehensive customization package that includes enhanced electrical sealing, lubrication system optimization, anti-rust oil channels, and basic disaster prevention structure recommendations, tailored to specific regional needs.

Pre-sale Support and Environmental Evaluation

Minnuo provides pre-sale environmental assessment services, helping to create a customized CNC machine configuration according to the client’s workshop structure and climate conditions, ensuring long-term and efficient operation.

For users in high humidity, high rainfall, or flood-prone areas, Minnuo is not just selling equipment; we provide a full suite of disaster-ready solutions.

Conclusion

The challenges posed by extreme weather to manufacturing equipment are growing, and machine tools, as high-value, long-term operational assets, require ever-higher environmental adaptability. If you are looking to purchase CNC machine tools for areas with frequent rain, high humidity, or flood risks, consider Minnuo's machines designed specifically for such conditions. We can offer tailored solutions to help you mitigate risks right from the start.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763