Regular maintenance

Max Longitudinal Travel: 1130mm · Table Size: 400×1000mm · Cross Travel: 450mm

The SGA Series Saddle Moving Surface Grinder is designed for high-precision surface grinding of small to medium-sized components, especially those with complex geometries. Featuring a cross-arm saddle layout and PTFE-coated guideways, it delivers consistent accuracy with smooth motion and stable support.

SGA Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Optimized Structural Layout: Features a cross-slide structure with PTFE-coated guideways to reduce friction and enhance stability, ensuring long-term grinding accuracy and machine durability.

- ● Stable Hydraulic Table System: A closed-loop hydraulic drive provides smooth, consistent longitudinal table feed, maintaining performance across extended grinding cycles.

- ● Flexible Vertical Feed Options: AHR models utilize a conventional motor-driven vertical lift for manual adjustment, while AHD models integrate servo motors and PLC control for programmable automatic infeed.

- ● Precision Grinding Performance: Outfitted with a high-rigidity spindle and dynamically balanced grinding wheel, the machine achieves superior flatness and surface finishes down to Ra ≤ 0.4 μm.

Recommended Configurations

- ● Spindle System: High-Precision Spindle, Spindle Motor and Cooling System

- ● Feed and Worktable System: Ball Screws, Linear Guideways, Magnetic or Mechanical Clamping System

- ● Grinding Wheel and Grinding Head System: Grinding Wheel Adjustment Device, Manual Dressing Tool

- ● Safety and Lubrication System: Protective Covers, Safety Doors and Emergency Stop Button, Automatic Lubrication System and Lubricant Oil Filtration Device

- ● Other: Grinding Wheel Dressing Tools and Workpiece Fixtures, Human-Machine Interface (HMI)

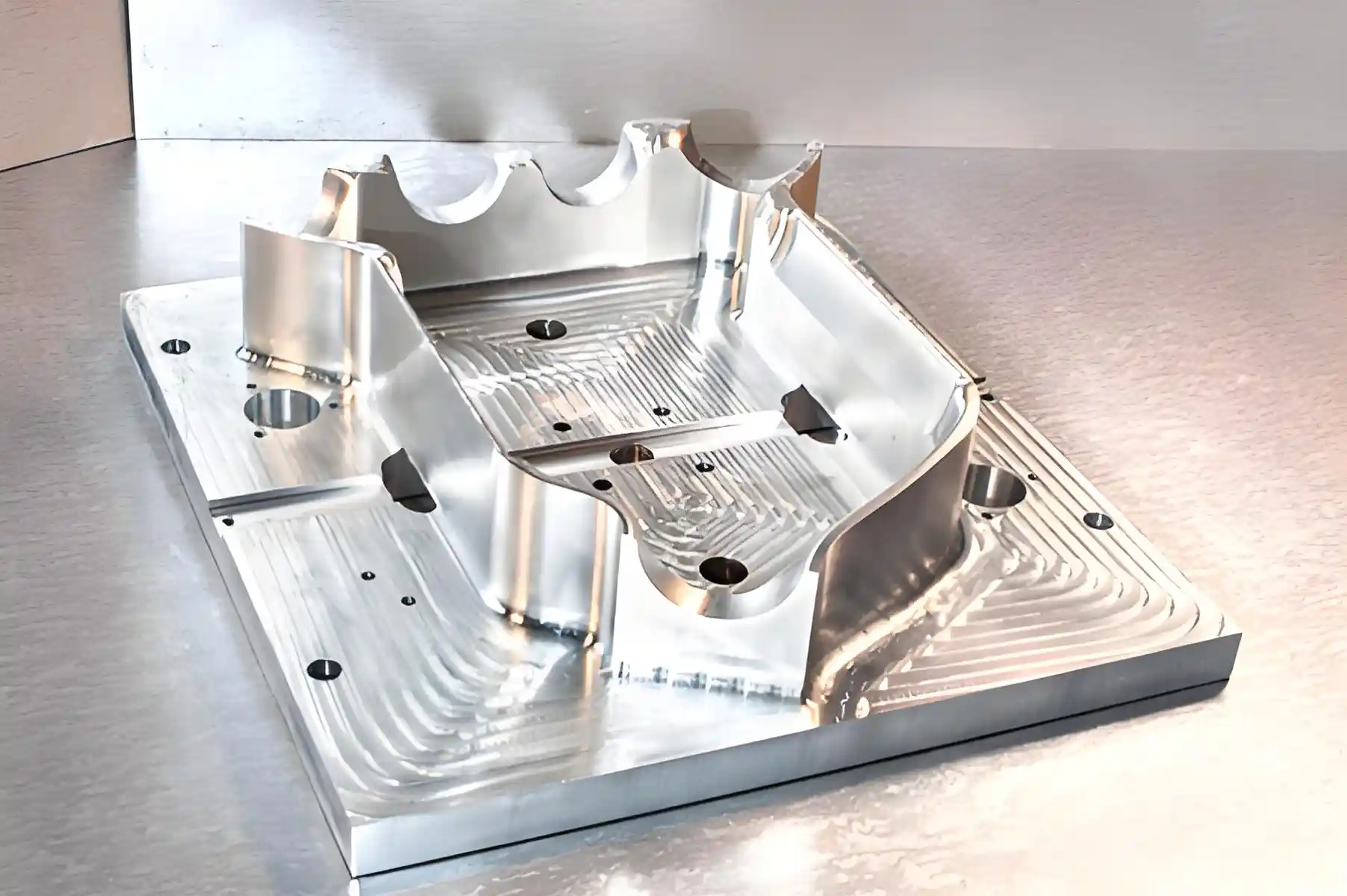

Application Case

- ● Client: Precision Tooling Manufacturer – Italy

- ● Use Case: Surface finishing of mold plates and gauge blocks

- ● Model: SGA-1000AHD with magnetic chuck and DRO

- ● Results: • Flatness deviation: ≤ 0.002 mm over 500 mm • Reduced setup time: –35% with servo automation • Operator efficiency: Improved by 40% due to programmable feed • Surface roughness: Achieved Ra ≤ 0.4 μm

- ● Client Feedback: “The SGA-AHD surface grinder offers high repeatability with minimal manual intervention. It has significantly streamlined our mold finishing process.”

Product Specifications

| Specification | Unit | SG-2050H/AH | SGA-2550AH | SGA-3063AH | SGA-30100AH | SGA-4080AH | SGA-40100AH | |

|---|---|---|---|---|---|---|---|---|

| SG-2050AHR | SGA-2550AHR | SGA-3063AHR | SGA-30100AHR | SGA-4080AHR | SGA-40100AHR | |||

| SG-2050AHD | SGA-2550AHD | SGA-3063AHD | SGA-30100AHD | SGA-4080AHD | SGA-40100AHD | |||

| Table size(w×L) | mm | 200×460 | 250×500 | 305×635 | 305×1020 | 406×813 | 406×1020 | |

| Max.longitudinal travel | mm | 510 | 560 | 765 | 1130 | 910 | 1130 | |

| Cross travel | mm | 238 | 275 | 340 | 340 | 450 | 450 | |

| Max.distance from spindle center to table | mm | 450 | 450 | 560 | 560 | 560 | 560 | |

| Magnetic chuck size | mm | 200×460 | 250×500 | 300×600 | 300×1000 | 400×800 | 400×1000 | |

| Speed of table longitudinal movement | m/min | 7~23 | ||||||

| Table transversemovement | Auto feed | mm/min | 0.1~8 | |||||

| Rapid speed | mm/min | 990 | ||||||

| Feed of handwheel | mm/div. | 0.02 | ||||||

| Wheelhead vertical movement | Auto feed | mm/stroke | ——(AH/AHR mode)0.005/0.01/0.02/0.03/0.04/0.05(Only for AHD model) | |||||

| Rapid speed | mm/min | (AH mode)460(Only for AHR/AHD model) | ||||||

| Feed of handwheel | mm/div. | 0.005 | ||||||

| Grinding wheel | Speed | rpm | 2850(50Hz)、3450(60Hz) | 1450(50Hz)、1750(60Hz) | ||||

| Size(OD×W×ID) | mm | 200×20×31.75 | 350×40×127 | |||||

| Spindle Motor | kW | 1.5 | 2.2 | 5.5 | ||||

| Hydranlic motor | kW | 1.5 | 0.75 | 2.2 | ||||

| Cooling pump motor | kW | 0.04 | 0.125 | |||||

| Elevating motor | kW | —(AH mode)0.25(AHR mode)0.5(AHD mode,servo motor) | ||||||

| Cross feed motor | kW | 0.08 | ||||||

| Max.loading capacity of table(include magnetic chuck) | kg | 120 | 180 | 270 | 400 | 500 | 600 | |

| Total rated power | kW | 3 | 3.7 | 9 | ||||

| Height of machine | mm | 1675 | 1890 | |||||

| Floor space(L×W) | mm | 1700×1200 | 2300×1650 | 2900×2200 | 4400×2200 | 3600×2400 | 4400×2400 | |

| Gross weight | kg | 1200 | 1800 | 2600 | 3300 | 3300 | 3700 | |

| Package dimensions(L×W×H) | mm | 1900×1720×2175 | 2000×2100×2175 | 2350×2220×2150 | 2950×2220×2210 | 2850×2270×2180 | 2950×2270×2210 | |

Catalog

Frequently Asked Questions

Yes. Minnuo has a professional and responsive technical support team. As long as you provide the part drawings, we can recommend a matching machine within 10 minutes for a single device. For multiple machines or a production line, we will provide a solution within 5 working days.

Yes, your company can provide customized CNC surface grinding machines for customers. Whether it's the control system, spindle power, automatic wheel change device, or exterior design, we can customize according to customer requirements to meet various processing needs.

Our manual surface grinding machines are suitable for small to medium batch production, repair workshops, and mold processing. They feature simple structure and easy maintenance, making them ideal for users with moderate automation needs but high precision requirements.

Yes, Minnuo is a professional surface grinding machine manufacturer with complete R&D, production, and testing systems. We provide both standard models and customized solutions, and have delivered equipment to customers in over 30 countries worldwide.

Minnuo has a complete set of basic production equipment. Whether it's the machine system, spindle speed, motor power, or sheet metal enclosure, we can provide customized solutions.

We are equipped with high-end machine tools from leading international brands to ensure the machining accuracy of components. Each surface grinding machine is rigorously tested before delivery and comes with a quality inspection report.

For standard models like manual surface grinding machines or regular CNC surface grinders, we have stock available for quick delivery. For customized models like the double column surface grinding machine, the delivery time is typically 30–45 working days, depending on the order.

Both are heavy-duty grinders. A gantry type surface grinding machine generally has a gantry structure, suitable for large workpiece surfaces. A double column surface grinding machine emphasizes rigidity and high precision, ideal for mold and precision part processing. We can recommend the right model based on your workpiece size and precision needs.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763