Mastering Large-Scale Machining: Overcoming Thermal Drift, Deflection & Setup on Gantry Machining Center

Conquering the Giants: Advanced Strategies for Maximizing Gantry Machining Center Precision & Productivity

Gantry Machining Centers are the undisputed powerhouses of industries like aerospace, energy, and heavy equipment manufacturing. They are engineered to handle massive workpieces that smaller machines cannot accommodate. However, the very scale that defines their purpose also introduces a unique set of complex challenges. If you are battling inconsistent part accuracy, wasting valuable production hours on lengthy setup, or facing mysterious deviations in your large-part programs, this comprehensive guide is for you. We move beyond basic tips to explore advanced, actionable strategies that will transform your gantry mill from a mere workhorse into a pinnacle of precision and efficiency.

The Inevitable Challenges of Scale: A Deeper Dive

Understanding the root cause of these challenges is the first step toward solving them. The issues are not simply operational; they are fundamental to the physics of large-scale machining.

1. Thermal Drift: The Silent Precision Killer

Imagine a steel ball screw that is 4 meters long. As the machine operates, friction from the drives and the ambient temperature of the workshop cause this screw to expand. While the expansion per meter is minute, over the total length, it can accumulate to 0.05mm, 0.10mm, or even more. This thermal growth results in positioning errors that are not constant; they change throughout the day, making them notoriously difficult to predict and compensate for manually. The consequence? A feature machined at the far-right end of the table in the afternoon will not align perfectly with a feature machined on the left in the morning, leading to scrap parts and costly rework.

2. Structural Deflection: The Unseen Force of Gravity

The challenge isn't just the machine moving; it's the machine moving under load. A gantry structure, while robust, is not infinitely rigid. The combined weight of a multi-tonne workpiece and the downward force of the spindle cutting can cause the entire bridge and the machine bed to flex minutely. This micro-deflection directly translates to variations in cutting depth, poor surface finish, and difficulty in holding tight tolerances, especially when machining deep pockets or critical vertical walls.

3. The Logistics of Large-Scale Setup

Efficiency in machining is not just about rapid metal removal. For gantry mills, the single biggest drain on overall equipment effectiveness (OEE) is often non-cutting time. Positioning a 5-tonne casting, meticulously indicating it to be perfectly square, and then securely clamping it without inducing stress can take hours, if not an entire shift. This process is not only time-consuming but also physically demanding and prone to human error.

From Reactive to Proactive: Advanced Solutions for the Modern Workshop

The modern solution set involves a combination of sophisticated technology, smart processes, and a proactive mindset. Here’s how leading manufacturers are gaining a competitive edge.

Solution #1: Winning the War on Thermal Drift

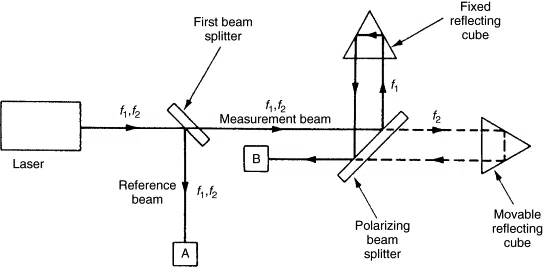

l Laser Interferometer Calibration: This is the gold standard. By having a specialist perform a volumetric error compensation analysis using a laser interferometer, you can create a detailed error map of your machine's entire work envelope. This map is then loaded into the CNC controller, which actively compensates for positioning errors in real-time, effectively negating the effects of thermal drift and inherent geometric inaccuracies.

l Thermal Stability Control: Many new high-end gantry machines come with active cooling systems for the ball screws and spindle. If your machine lacks this, consider controlling the ambient temperature of your shop floor as much as possible. Even a consistent temperature of ±2°C can dramatically improve long-run accuracy.

Solution #2: Engineering Around Deflection

l Proactive Bed Mapping & Shim Planning: Before placing the workpiece, run a precision indicator across the machine table to map its flatness under no load. Use this data to strategically place precision ground shims at high-load points before the part is lowered, creating a "virtual flat plane" and pre-emptively countering bed sag.

l Lightweight, High-Power Spindle Technology: The industry is moving towards spindles made with composite materials that offer the same power with significantly less weight. This reduces the static droop of the spindle head, a major contributor to Z-axis inaccuracy.

Solution #3: Revolutionizing Large-Part Setup

l The Power of Pallet Systems: For repeat production of large parts, a large-scale pallet system is a game-changer. While a significant investment, it allows you to pre-set the next workpiece on a separate station while the current one is being machined. This reduces machine idle time from hours to minutes, skyrocketing your utilization rate.

l Advanced Probing & Multi-Coordinate Mastery:

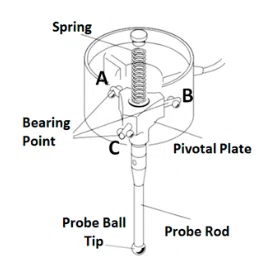

A 3D touch probe is non-negotiable for modern gantry machining. It automates the finding of part datums, edges, and even can measure the workpiece after a roughing cycle. Coupled with the intelligent use of multiple work coordinate systems (G54, G55, etc.), it allows you to machine a massive part as if it were a series of smaller, more manageable components, all tied back to a single, unchangeable master datum.

The Future is Here: Integrating Predictive Maintenance and Data

The journey doesn't end with setup and calibration. The most advanced workshops are now leveraging IoT (Internet of Things) sensors to monitor machine health. Vibration sensors on the spindle and load meters on the axis drives can predict maintenance needs before a catastrophic failure occurs, maximizing uptime for your most critical asset.

Stop Fighting Your Machine, Start Mastering It

The challenges of gantry machining are a test of engineering and process discipline. By moving from reactive fixes to a strategic, technology-enabled approach, you can turn these inherent challenges into your greatest competitive advantage.

Let's Turn Your Largest Projects Into Your Most Profitable Ones.

Our team of application engineers specializes in optimizing gantry machining processes. We provide cutting-edge solutions, from equipment recommendation to full process design.

Schedule a Free, No-Obligation Machining Process Audit with Our Experts Today!

Email

Email sales1: +86 13295238763

sales1: +86 13295238763