The difference and cooperation between boring machine and milling machine: an article to understand the selection and collaborative application of processing equipment

In the field of mechanical processing, boring machines and milling machines are two widely used key equipment types. While they differ in functionality, they can achieve high-precision machining of complex parts through coordinated operation. Many industry practitioners often confuse their application scenarios when selecting equipment or planning processes. This article will clarify the application logic of these two devices from three aspects: core differences, collaborative scenarios, and selection recommendations, providing practical references for production processing.

I. Core differences between boring machine and milling machine: from principle to application scenario

To use boring machine and milling machine correctly, we must first clarify the essential differences between them in processing principle, precision characteristics, applicable workpiece and other dimensions, so as to avoid low processing efficiency or unqualified precision due to wrong selection.

1.Processing principle: The core difference between "rotating tool" and "rotating workpiece"

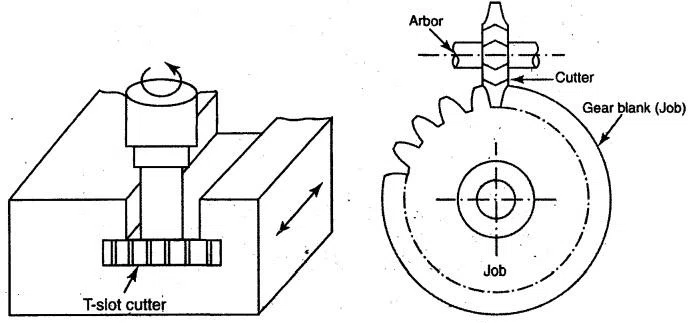

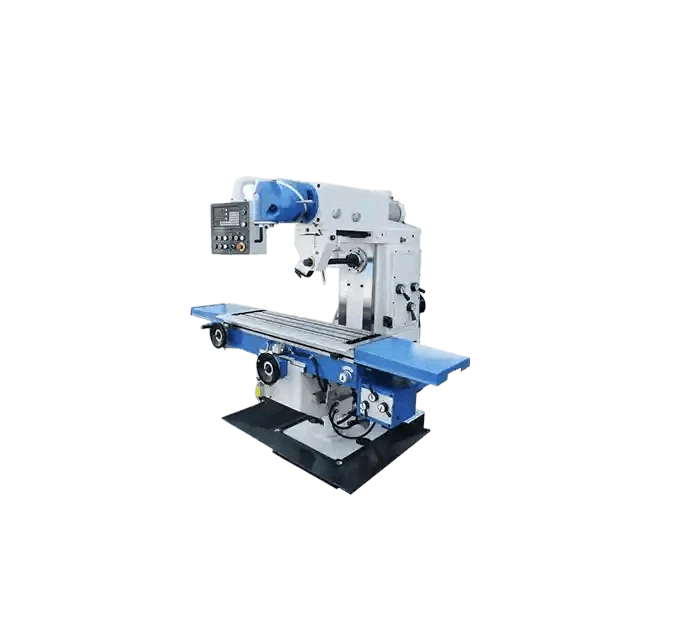

• Milling Machine: The primary motion involves rotating cutting tools while the workpiece undergoes linear or curved feed movements guided by the worktable. For example, vertical milling machines utilize a spindle to drive high-speed milling cutters while the worktable performs vertical and lateral movements of the workpiece, enabling machining of surfaces, grooves, gears, and other structures. The core principle follows the "tool-driven cutting, workpiece-passive feed" mechanism, making it ideal for batch processing of small-to-medium-sized parts with smooth surfaces or regular geometries.

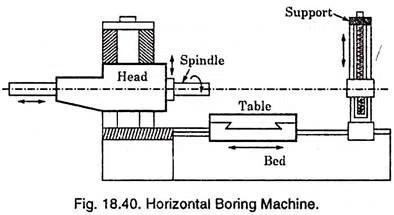

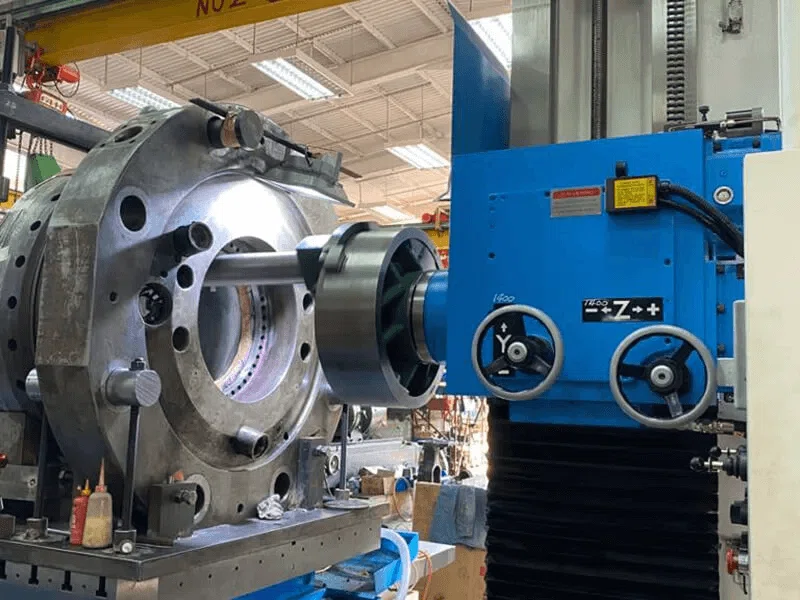

• Boring Machine: The primary motion consists of workpiece fixation, rotating boring tool, and axial feed. In some scenarios, the worktable can also be used to fine-tune the workpiece position. For example, in horizontal boring machines, the spindle rotates the boring tool while moving axially to achieve deep-hole machining, or a rotary table drives radial feed for end face and outer diameter processing. The core principle is "the tool combines rotation and feed with the workpiece remaining relatively stationary," making it particularly effective for large workpieces' hole systems and internal surface treatments.

2.Precision characteristics: emphasis on the difference between "hole system precision" and "surface precision"

• Milling machines excel in precision control of flatness, perpendicularity, and contour accuracy. Conventional milling machines achieve surface precision up to IT8-IT9 grades, while high-precision CNC milling systems can reach IT7 standards. When machining mold cavities or component positioning surfaces, milling machines ensure surface roughness (Ra value) as low as 1.6μm through high-speed cutting technology.

• Boring Machine: The core advantage lies in its precision hole system processing capabilities, particularly excelling in deep-hole and coaxial hole operations. For instance, horizontal boring machines can maintain radial runout of shafts within 0.005mm, achieve IT6 dimensional accuracy for holes, and control coaxiality errors in coaxial holes to within 0.01mm/m. These features meet the stringent hole system requirements for critical components such as engine blocks and machine tool spindles.

3.Applicable workpiece and machining scenario: Complementary rather than substitutive

dimension | arm brace | boring mill |

Workpiece size and weight | Small and medium sized workpieces (weight usually <500kg) | Large, heavy duty workpieces (weight up to several tons) |

Core processing content | Planes, grooves, gears, cavities | Deep hole, coaxial hole, step hole, internal thread |

Typical application areas | Mold manufacturing, light industrial parts, electronic products | Heavy machinery, construction machinery, aerospace |

Processing efficiency (batch production) | Higher (suitable for standardized batch processing) | Low (suitable for high precision single piece/small batch) |

II. The coordination between boring machine and milling machine: a 1+1> 2 processing scheme

In the processing of complex parts, a single equipment can not meet all the requirements. The cooperation between boring machine and milling machine can achieve a seamless connection of "surface processing + hole system processing", improving the overall machining accuracy and efficiency. The following are two typical cooperation scenarios:

1. Large box parts: "milling rough processing → boring precision processing"

Taking the machining of machine tool spindle housing as an example, its machining process needs to combine the advantages of two types of equipment:

• Step 1: Milling Roughing: Use a vertical milling machine to mill the top, bottom, and side surfaces of the spindle housing. This process removes surface allowances from the blank (typically leaving 0.5-1mm for precision machining) while creating positioning reference planes that ensure accurate alignment for subsequent boring operations. This step efficiently removes substantial material allowances, preventing prolonged roughing stages from compromising the boring machine's precision stability.

• Step 2: Lathe Precision Machining. The rough-machined spindle housing is secured on the lathe table and positioned using a milling machine's reference surface. Key holes including the spindle bore and bearing bore are machined through a horizontal lathe. This single-process system performs boring, reaming, chamfering, and internal threading operations to ensure coaxiality, perpendicularity, and dimensional accuracy of the hole assembly, ultimately meeting the spindle housing's assembly requirements.

2. Complex structure: "boring machine pretreatment → milling machine deep processing"

In the machining of complex frame parts in the field of aerospace, it is necessary to ensure the accuracy of hole system through boring machine first, and then complete the complex surface processing through milling machine:

• Step 1: Boring Machine Preparation: First, drill positioning and connection holes in the frame using a boring machine. These holes will serve as reference points for subsequent milling operations (e.g., insert positioning pins into the reference holes to ensure precise part fixation on the milling table). The precision of these bore holes directly determines the positional accuracy required for subsequent milling processes.

• Step 2: Milling Precision Machining: Using the reference hole processed by a boring machine as the positioning benchmark, a five-axis coordinated milling machine is employed to fabricate complex structures such as irregular curved surfaces and inclined grooves on the frame. The five-axis milling system enables machining of intricate contours through multi-directional feed movements. Meanwhile, the reference hole pre-processed by the boring machine eliminates positional errors caused by secondary part clamping, ensuring precise positional accuracy between curved surfaces and the hole system (e.g., perpendicularity error between holes and curved surfaces <0.02mm).

III. Suggestions for the selection of boring machine and milling machine: match the equipment according to the demand

In actual production, it is necessary to select the model comprehensively according to processing requirements, precision requirements and cost budget, or formulate a "single machine use + coordination" scheme:

1. Priority milling machine scenarios: If the processing requirements are mainly planes, grooves, and regular contours, and the workpiece size is small and the batch is large (such as mobile phone middle frame, mold cavity), the CNC milling machine can meet the requirements, and the processing efficiency is higher and the equipment cost is lower (the price of conventional CNC milling machine is about 1/3-1/2 of the boring machine with the same precision).

2. Scenarios that prioritize boring machine: If it involves deep hole (hole depth> 5 times the hole diameter), coaxial hole, and hole system processing of large workpieces (such as hydraulic cylinder tube of construction machinery, engine cylinder body), boring machine must be selected, especially horizontal boring machine or floor boring machine, whose precision and rigidity can ensure the quality of hole system processing.

3. Recommended workflow: For components containing both complex surfaces and high-precision hole systems (e.g., large casings or aerospace frames), the optimal approach combines "milling roughing + boring finish" or "boring reference hole + milling complex surfaces". This dual-process strategy ensures precision while maximizing efficiency, effectively avoiding the accuracy loss or operational inefficiency that might occur with single-machine processing.

Sum up

Boring machines and milling machines are not "displacement tools" but rather "complementary partners" in mechanical processing: Milling machines excel at surface and contour machining of small-to-medium parts with high efficiency and cost-effectiveness, while boring machines specialize in high-precision hole systems for large workpieces with superior accuracy and rigidity. By understanding their core differences and developing tailored "single-machine processing + collaborative coordination" strategies based on practical needs, manufacturers can maximize production efficiency while maintaining processing precision, effectively meeting component manufacturing demands across various industries.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763