Regular maintenance

φ3000mm Max Swing · φ2500mm Max Swing Over Tool · 3T Max Weight · 750mm Max Length

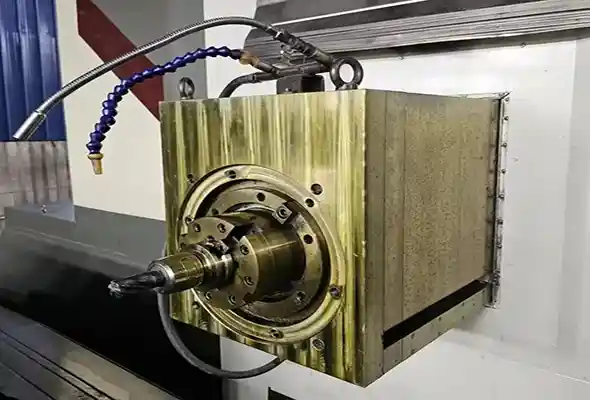

The TK6920A is a high-capacity CNC floor boring and milling machine, designed for large-scale turning, facing, and grooving applications. Built with a rigid three-support spindle, this model delivers excellent vibration resistance and cutting stability during both rough and finish machining.

TK Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Wide swing diameter support up to 3000mm for oversized parts

- ● Three-point spindle support for high rigidity and precision during deep cuts

- ● Suitable for both roughing and precision finishing operations

- ● Forced lubrication system reduces thermal wear and improves service life

- ● Efficient chip evacuation design improves workflow and reduces downtime

- ● CNC programmable for complex paths and multi-surface operations

Recommended Configurations

- ● Auto tool turret: Enables quick change between roughing and finishing tools.

- ● Hydraulic steady rest: Stabilizes long or heavy cylindrical parts during cutting.

- ● Programmable tailstock: Provides additional support for shaft-type components.

- ● High-torque spindle motor: Delivers constant power at low speeds for heavy cuts.

- ● Heavy-duty chip conveyor: Optimizes chip flow and machine cleanliness.

- ● Operator protection enclosure: Ensures safety during large-part operation.

Application Case

- ● Client: Wind Turbine Hub Manufacturer – Spain.

- ● Use Case: Boring and facing large-diameter cast steel hubs for wind turbine rotors.

- ● Setup: TK6920A equipped with hydraulic tailstock, chip conveyor, and enhanced coolant system.

- ● Results: Dimensional tolerance: ±0.02 mm across 2.4 m diameter, operation time: 12+ hours continuous machining per setup, tool change efficiency improved by 40%, client feedback: “We needed a machine that could handle big, heavy castings with repeatable precision — the TK6920A exceeded expectations in both speed and finish.”

Product Specifications

0

Catalog

Frequently Asked Questions

Minnuo’s floor boring machines are ideal for large, heavy workpieces such as turbine casings, wind tower bases, marine engine blocks, large gearbox housings, and heavy-duty machine frames.

A typical floor boring machine consists of a moving column (or ram), stationary worktable or floor plates, high-rigidity bed structure, and often multiple milling and boring heads for multi-side machining.

Our floor borers can achieve positioning accuracy within ±0.01–0.02 mm and repeatability within ±0.008 mm, with surface roughness reaching Ra 0.8–1.6 μm, depending on the cutting system and tooling.

Absolutely! Just send us your workpiece size, weight, required machining areas, and material information, and we’ll recommend the appropriate floor boring machine model within 10 minutes.

Yes! We offer customizations like column travel length, spindle diameter and power, worktable size, automatic tool changers (ATC), rotary tables, and integration with automation lines.

Minnuo uses high-grade Meehanite casting, servo drive systems, hydrostatic guideways (optional), laser calibration, and full trial cutting tests to guarantee top machining precision and stability.

Standard models are delivered within 90–120 working days. Fully customized large floor borers may require 120–180 working days depending on specifications.

Minnuo provides a one-year warranty, 24/7 technical support, online setup training, remote troubleshooting, on-site services, and long-term spare parts support (10+ years).

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763