Regular maintenance

Up to 2600 mm workpiece height • Max. 16T load capacity • Sliding or hydrostatic table options

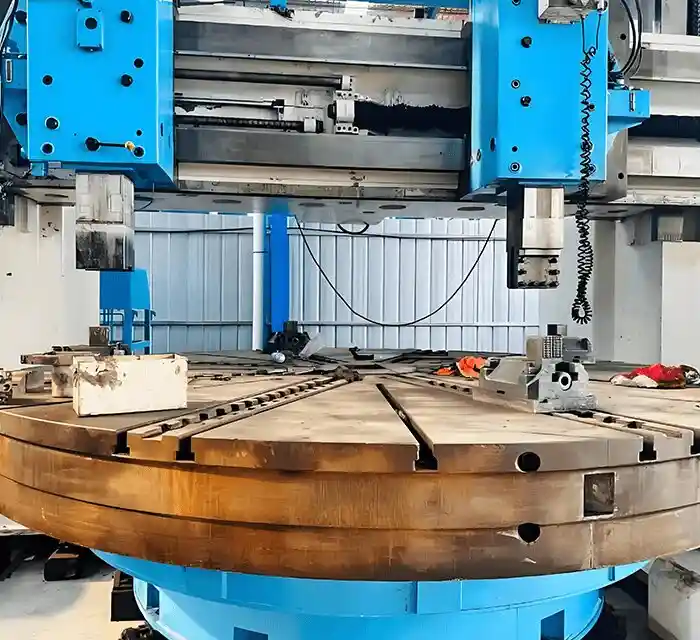

The C5225E Series double-column vertical turret lathe turns large heavy-duty cylindrical/disc components with Ø2500 mm max diameter and 16-ton table load, ideal for power, shipbuilding, metallurgy, and heavy manufacturing. It offers AC/DC drives, sliding/hydrostatic guideways, and OMRON PLC-controlled turning of inner/outer cylinders, cones, faces, and grooves.

C5225E Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Heavy-Duty Dual Column Construction: Built for large-diameter workpieces, the machine features a dual-column structure with a resin sand cast base and columns. All castings are heat-treated and aged to ensure excellent rigidity and long-term accuracy retention.

- ● Customizable Table Drive & Guideway: Offers user-selectable configurations: sliding guideway for cost-effective performance or hydrostatic guideway for ultra-smooth rotation under heavy loads. The main drive system supports both AC and DC motors to accommodate various torque and speed requirements.

- ● Programmable Control System: Utilizes an OMRON PLC for precise spindle logic control and reliable machine operation. All electrical components are sourced from Schneider or Siemens to guarantee industrial-grade reliability and global support.

- ● Precision Multistage Feed System: An 18-speed AC feed mechanism ensures smooth, variable-speed tool movement across extended vertical and horizontal axes, supporting high-precision machining over large travel distances.

Recommended Configurations

- ● Side Tool Holder (Optional): Allows for additional machining operations on external contours or inner surfaces, increasing process flexibility and reducing setup time.

- ● Digital Readout (DRO): Provides accurate visual feedback for vertical and horizontal tool positioning, improving manual alignment precision and reducing human error.

- ● Cooling System with Directional Nozzle: Improves chip evacuation and thermal control during extended roughing cycles, maintaining workpiece quality and protecting cutting tools.

- ● Hydraulic Chucking System: Ensures firm and concentric clamping of large-diameter components, supporting high-accuracy machining under heavy load conditions.

- ● Enclosure & Mist Collector: Maintains workshop cleanliness and enhances operator safety by containing debris and capturing airborne coolant mist during heavy-duty operations.

Application Case

- ● Client: Petrochemical Equipment Manufacturer – Brazil

- ● Workpiece: Ø2300 mm pressure vessel end plates

- ● Setup: C5225E with hydrostatic table, AC main drive, DRO, and side tool holder

- ● Results: • Roundness control: ≤ 0.025 mm over entire diameter • Cycle time improvement: 30% faster than previous model • Surface finish: Ra ≤ 1.6 μm achieved with final pass

- ● Customer Feedback: “The dual-column structure gives us superior stability during deep cuts, and the hydrostatic table makes heavy turning extremely smooth. This machine is a solid performer for our oversized components.”

Product Specifications

0

Catalog

Frequently Asked Questions

Minnuo vertical turret lathes are ideal for heavy, large-diameter disc or ring-shaped workpieces, such as flanges, valve bodies, turbine housings, large bearings, and gearbox cases.

A VTL provides better support for large, heavy parts, minimizes deformation during machining, offers easier loading/unloading, and allows multi-tool machining with a turret for improved efficiency.

Our vertical turret lathe machines support turning, facing, boring, grooving, threading, and optional live tooling functions for drilling and light milling — all in one setup.

Yes! Minnuo's technical team can recommend a matching vertical turret lathe model within 10 minutes based on your workpiece drawings. For full production line solutions, we deliver a detailed plan within 5 working days.

Absolutely. We can customize table diameter, machine height, spindle motor power, turret type, number of tool stations, and even add live tooling systems according to your specific needs.

Our vertical turret lathes use high-grade Meehanite cast iron beds, precision-ground guideways, and are subjected to geometric accuracy testing, spindle radial runout inspection, and trial machining before delivery.

Standard models are usually delivered within 20–30 working days. Fully customized vertical turret lathes typically require 45–60 working days depending on complexity.

Minnuo provides a one-year warranty and 24/7 technical support. We also offer remote troubleshooting, on-site repairs, and long-term parts supply support for more than 10 years after purchase.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763