Regular maintenance

Worktable size: 390×615mm,X, Y axis travel: 320×400mm,Max. cut thickness Z: 300mm

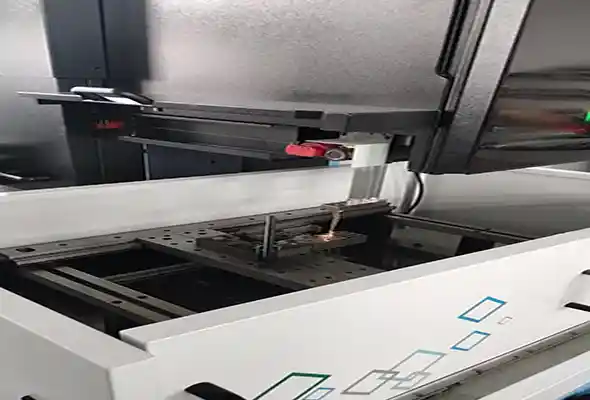

The DK7732HA is a medium-format reciprocating wire EDM machine built for precision cutting of conductive materials with moderate thickness. Featuring 320×400mm travel range and up to 300mm Z-axis capacity, it’s ideal for mold inserts, tool bases, and die plates. Its stable frame, responsive wire drive, and optimized flushing system ensure consistent straightness and surface finish for daily high-accuracy operations.

DK77HA Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● 390×615mm worktable supports multi-part setups and medium-scale molds.

- ● 320×400mm XY travel for complex shapes and large-profile processing.

- ● Max. cutting thickness of 300mm for mid-thick steel, copper, and alloy blocks.

- ● Reciprocating wire motion enhances cutting depth stability.

- ● Servo-driven axis control ensures repeatability and smooth path transitions.

Recommended Configurations

- ● Water-cooled dielectric system: Improves cut precision and cooling during deep cuts.

- ● Fine filtration unit: Ensures clean fluid for precision finishing.

- ● Auto wire threading unit: Saves operator time and boosts daily throughput.

- ● Graphite-friendly wire system: Reduces wear and maintains accuracy with brittle materials.

- ● Fixture plate with indexing slots: Enhances part setup flexibility for repeatable jobs.

Application Case

- ● Client: Precision Mold Supplier – South Korea.

- ● Use Case: Cutting mold cavity inserts with internal pockets and complex angles.

- ● Setup: DK7732HA with water-cooled system, fine brass wire, and high-precision base plate fixture.

- ● Results: Contour profile deviation: ≤ ±0.008 mm, surface finish Ra: ≤ 2.2 μm, completed 4 cavity blocks/day on single shift, client feedback: “We rely on DK7732HA for daily production—it’s stable, fast, and accurate.”

Product Specifications

| Specifications | Unit | DK7732HA | DK7740HA | DK7750HA |

|---|---|---|---|---|

| Worktable size | mm | 390*615 | 480*720 | 580*880 |

| X,Y axis travel(X*Y) | mm | 320*400 | 400*500 | 500*600 |

| Max.cut thickness Z | mm | 300 | 300 | 350 |

| U,V axis travel | mm | 60*60 | ||

| Diameter of Mo.wire | mm | Molybdenum wireφ0.12~φ0.18 | ||

| Wire speed | 7-speed adjustable | |||

| Taper angle/workpiece thickness | °/mm | 3°/60mm | ||

| Process accuracy(vertical) | mm | Multi-cut:10×10×30 Squire≤0.006One-cut:≤0.012 Octagon≤0.009 | ||

| Process roughness | μm | Multi-cut:Ra≤1.2 One-cut:Ra≤2.5 | ||

| Motor drive system | Stepper motor(Option:Servo motor) | |||

| Screw&Guides(X,Y) | Precision ball screw/Linear motion guides | |||

| Wire tension | Precision spring automatic tensioning mechanism | |||

| Working fluid/capacity | L | Complex or water-soluble special coolant/65L | ||

| Power supply | AC 3-φ380V 2KW | |||

| Max.table carry | kg | 300 | 400 | 500 |

| Net weight | kg | 1600 | 1800 | 2500 |

| Dimensions | mm | 1600*1250*2180 | 1850*1500*2200 | 2100*1800*2400 |

Catalog

Frequently Asked Questions

Minnuo’s medium speed wire EDMs are ideal for precision molds, complex mechanical parts, fine stamping dies, connector components, and electronic parts requiring high dimensional accuracy and good surface finish.

Medium speed wire EDM combines the low cost of fast wire EDM with better accuracy and surface finish close to slow wire EDM, using one-time cutting plus multiple skim cuts to balance precision and efficiency.

Minnuo’s medium speed wire EDM machines achieve positioning accuracy within ±0.005 mm, surface roughness up to Ra 0.8–1.2 μm, and can support multi-pass fine cutting.

Absolutely! Send us the workpiece material, thickness, dimensional tolerance, and we’ll recommend the most suitable medium speed wire EDM model within 10 minutes.

Yes! We offer customizations like worktable size, maximum cutting thickness, wire diameter compatibility, water tank capacity, CNC controller brand, and automatic wire threading (AWT) systems.

We use high-rigidity casting structures, precision ball screw drives, high-frequency power supplies, and perform multi-cut testing and laser interferometer calibration before shipment.

Standard models are delivered within 20–30 working days. Customized models or machines with AWT systems typically require 30–45 working days.

Minnuo provides a one-year warranty, 24/7 technical support, remote training, troubleshooting assistance, and long-term spare parts availability.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763