Regular maintenance

φ1260mm Table · 750kg Load · 600mm Max Height

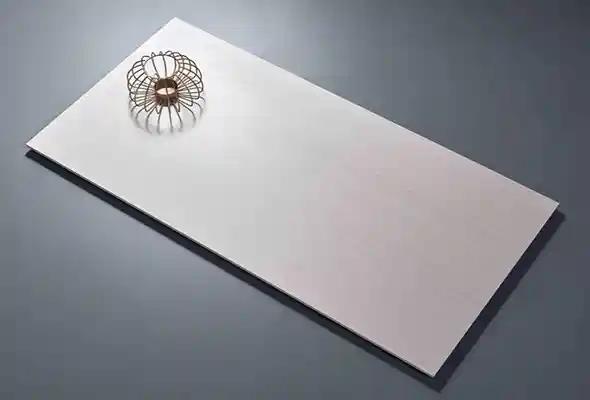

The SX7763-H is the largest model in the SX77-H Series of CNC ring wire abrasive cutting machines. It utilizes a unidirectional diamond-coated ring wire system to achieve precise, smooth, and low-vibration cutting on thick, fragile, and dense non-metallic materials.

SX77-H Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Extra-large cutting table supports heavy and wide-format workpieces

- ● Unidirectional ring wire system eliminates reverse motion, reducing vibration

- ● CNC-controlled for multi-pass, layered, and angular cutting programs

- ● Ideal for high-volume processing of quartz, ceramics, glass blocks, and sapphire

- ● Excellent surface finish and minimal micro-cracking on cut edges

Recommended Configurations

- ● Heavy-duty Loop Wire Tensioner Ensures consistent abrasive tension for long cuts

- ● Extended Table Clamping Set Safely stabilizes wide-format blocks

- ● Mist and Dust Spray Nozzles Protect edges from thermal stress and micro-fractures

- ● Dust Capture System Keeps cutting zone clean and prevents particle spread

- ● Integrated Cooling Maintains process stability and edge integrity

- ● Programmable CNC Interface Enables step-cut sequencing and nested cutting paths

- ● Load Lift Integration Module Assists in positioning and removing heavy materials safely

Application Case

- ● Client: Aerospace Ceramic Insulation Supplier – Germany

- ● Use Case: Precision slab cutting of 600mm-thick advanced ceramic panels for thermal shielding

- ● Setup: SX7763-H with automated loop tensioning, programmable slicing patterns, and mist enclosure

- ● Results: Flatness deviation: ≤ ±0.020 mm, surface quality: ready for direct bonding without additional finishing, productivity gain: cut cycle time reduced by 30%, client feedback: “The SX7763-H is the only solution we found that can handle our oversized panels with such consistent precision and clean surfaces.”

Product Specifications

0

Catalog

Frequently Asked Questions

Minnuo’s CNC abrasive wire cutting machines are ideal for hard and brittle materials such as sapphire, silicon wafers, silicon carbide, ceramics, quartz, magnetic materials, and rare metals.

A diamond-coated or abrasive wire continuously moves through the workpiece under controlled tension, achieving precise material removal by micro-grinding action, ideal for high-precision, low-damage cutting.

Our machines achieve cutting accuracy within ±0.01–0.02 mm, and surface roughness Ra 0.4–0.8 μm, depending on material properties and cutting parameters.

Absolutely! Just send us your material type, block size, required cut thickness, and tolerance, and Minnuo’s engineers will recommend the best abrasive wire cutting machine within 10 minutes.

Yes! We offer customizations including cutting stroke (X/Y/Z), maximum workpiece size, wire type (single wire/double wire), tension control system, and CNC system brand based on customer requirements.

Minnuo machines feature high-stability tension control, servo-driven wire feeding, constant wire speed regulation, and are calibrated with laser interferometer and precision measuring instruments before shipment.

Standard models are delivered within 30–45 working days. Customized or high-end versions usually require 45–60 working days.

Minnuo provides a one-year warranty, 24/7 technical support, remote online guidance, on-site commissioning services, and long-term spare parts support.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763