Regular maintenance

Ultra-precise · Stable· Micro-tolerance capable

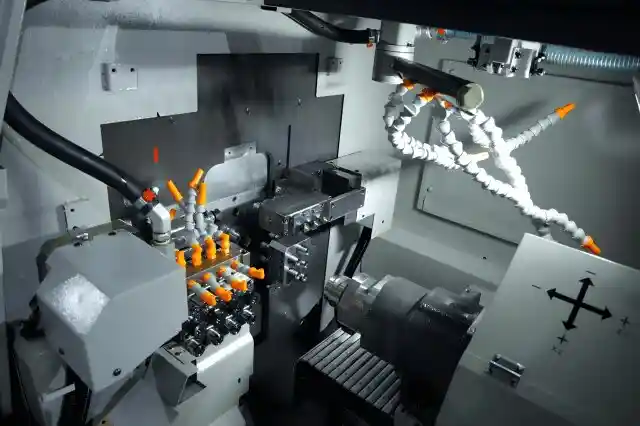

The DRF38-5 is a high-modularity Swiss-type CNC lathe engineered for the mass production of small, precise, and complex shaft-type components. With a maximum machining diameter of Ø38mm, drilling up to Ø23mm, and tapping up to M16, it is built for high-speed, multi-process, and multi-axis operations—all in a single clamping setup.

DRF Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Main and Back Spindle: The spindles are equipped with imported NSK bearings and THK guide rails for high precision and stability. The system supports up to 6 power-driven tools, allowing simultaneous operations like drilling, tapping, and milling.

- ● High-Speed Front Tool Head: Capable of reaching speeds up to 10,000 rpm, this front tool head significantly reduces machining time for small-diameter holes, improving overall production efficiency.

- ● Efficient Part Discharge System: The fixed product discharge chute allows for quick and efficient part removal without interfering with the front tool head, reducing part recovery time to just 1 second for seamless operation.

- ● Oil-Cooled Motor Spindle: The spindle features comprehensive oil cooling, maintaining consistent performance during high-speed machining, improving tool life and machining accuracy.

Recommended Configurations

- ● Hydraulic or Pneumatic Chuck: Provides stable and repeatable clamping for both small and large workpieces, making it ideal for high-volume machining applications.

- ● Automatic Tool Length Measurement: Automatically detects and sets precise tool offsets, improving machining accuracy and minimizing manual setup time.

- ● Coolant System with Filtration: Delivers effective cooling during high-speed operations while filtering contaminants to ensure consistent coolant quality and longer tool life.

- ● Bar Feeder Interface: Enables continuous feeding of long bar stock, supporting uninterrupted production and reducing overall cycle time.

Application Case

- ● Client: Precision Connector Manufacturer – UK

- ● Workpiece: Miniature components for electronic connectors

- ● Setup: DFR Series Swiss-Type Lathe with 6-tool live turret and high-speed front tool head

- ● Results: • Precision: Maintained tight tolerances of ±0.002 mm on small parts • Efficiency: Reduced cycle time by 30% with the high-speed front tool head and multi-tool capability • Surface Quality: Achieved surface finishes of Ra ≤ 1.2 μm Client Feedback: “The DFR Series lathe has significantly boosted our productivity, enabling us to handle complex operations with minimal downtime and excellent quality.”

Product Specifications

| Model | FR25-5 | FR20-6 | FR20-6S | FR20-5B | FR12-5 | ZR20-5 | MFR32-5 | DFR38-6 | DFR38-5 | ZR20-3 | FR25-9 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Max.machining diameter | φ20mm/φ25mm | φ12 mm | Φ20mm | Φ32mm | Φ38mm | φ38mm | φ20mm | φ25mm | |||

| Max.headstock strokeWith guide bush | 200mm | 135mm | 90mm | 190mm | 230mm | 230mm | 90mm | 260mm | |||

| Without guide bush | 1:2.5D | 1:2.5D | 1:2.5D | 1:2.5D | 1:2.5D | 1:2.5D | 1:2.5D | 1:2.5D | |||

| Max.headstock stroke Max.drilling capability | 10mm | φ8mm | φ10mm | φ7mm~φ13 mm | φ23mm | φ23mm | φ10 mm | φ10mm | |||

| Max.tapping capability | M8 | M6 | M8 | M6/M8/M12 | M16 | M16 | M8 | M8 | |||

| Max.drilling capability | φ8mm | φ5mm | φ8mm | φ7mm~φ10mm | φ13mm | φ13mm | φ8mm | φ8mm | |||

| Max.tapping capability | M6 | M4 | M6 | M6/M8 | M10 | M10 | M6 | M6 | |||

| Power-driven attachment Spindle speed | max.1.0000min | max.9.000min¹ | max.6000min¹ | max.6.000min¹ | max.6000min¹ | max.6000min⁴ | max.6000min | max.6000min | |||

| Power-driven attachment Driven motor | 1.0kw | 1.0/1.1kw | 1.0/1.1kw | 1.0/1.1kw | 0.9kw | 0.75KW | 1.7kw | 3.1KW | 3.1KW | 0.75KW | 1.0kw |

| Sub spindle tools Max.drilling capability | φ8mm | φ5mm | / | φ7mm | / | / | / | / | |||

| Sub spindle tools Max.tapping capability | M6 | M4 | / | M8 | / | / | / | / | |||

| Sub spindle tools Driven motor | 1.0kw | 1.1kw | 1.1kw | 1.0kw | 0.9kw | / | 1.7kw | / | / | / | / |

| Rapid feed rate | Z₁Y₁X₂Z2:32m/min | 24m/min¹ | 24m/min、max.5.000min¹ | / | / | / | / | ||||

| Main spindle speed | max.10000min¹ | max.10000min | max.10000min | max.10000min¹ | max.10000min¹ | max.10001min | max.6000min | max.6000min | max.6000min | max.10000min | max.10000min |

| Main spindle motor | 2.2kw(continuous)、3.7kw(10min./25%ED) | 2.2kw(continuous)、3.5kw(10min./26%ED) | 3.5kw(continuous)、6.0kw(10min./25%ED) | 11kw(continuous)、15kw(10min./25%ED) | 2.2kw(continuous)、3.5kw(10min./15%ED) | ||||||

| Sub spindle Max.travel distance | 265mm | 367mm | 367mm | 265mm | 265mm | / | 270mm | 30m/min | 30m/min | 24m/min | 32m/min |

| Machine weight | 3050kg | 3600kg | 3600kg | 3200kg | 1900kg | 2540kg | 3880kg | 4200kg | 4200kg | 1785kg | 3900kg |

Catalog

Frequently Asked Questions

Our Swiss type lathes are ideal for small-diameter, long, and high-precision parts, such as medical implants, aerospace pins, micro shafts, watch parts, and automotive precision components.

Unlike traditional lathes, Swiss type lathes use a sliding headstock and a fixed guide bushing, allowing the material to move close to the cutting tool, reducing deflection and achieving extremely high precision for slender parts.

Minnuo Swiss type lathes achieve positioning accuracy within ±0.002 mm, and surface finish up to Ra0.2μm, perfect for ultra-precision industries like medical and electronics.

Of course! Minnuo’s pre-sales engineers will recommend the right Swiss type lathe model within 10 minutes after reviewing your part drawing. For full production line setups, we can offer detailed solutions within 5 working days.

Absolutely. We offer customizations including automotive swiss-type machining lathe parts likespindle power, number of live tooling positions, back working capabilities, guide bushing types, and bar feeder integration to meet your special production needs.

We use high-quality hardened steel structures, high-precision spindles, and all machines undergo thermal stability tests, geometric precision tests, and full trial machining before shipment.

Standard models can be delivered within 20–25 working days. For customized configurations, delivery times are typically 30–45 working days.

Minnuo provides a one-year warranty, 24/7 technical support, and remote video diagnostics. We also ensure 10+ years of spare parts supply and offer operator training services upon request.

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763