Regular maintenance

135/370mm Axis Travel · Y-Axis ±30mm · Compact High-Precision Turning-Milling Solution

The MNT25Y is a high-performance CNC turning-milling center designed to deliver precision, stability, and versatility in compact part production. Featuring X-axis travel of 135mm, Z-axis of 370mm, and a dedicated Y-axis travel of ±30mm, it allows for multi-axis simultaneous machining, reducing setups and improving part complexity handling.

MNT25Y/MNT50Y Series

Spare parts supply

On-site installation service

Customized design

Why Choose Our CNC Solutions

Key Features

- ● Compact Travel, High Precision:X = 135mm · Z = 370mm · Y = ±30mm — ideal for detailed contouring, side milling, and off-center drilling.

- ● Integrated Y-Axis for Off-Center Features:Enhances machining flexibility for complex profiles and multi-surface operations.

- ● Machining Length up to 235mm:Suitable for short shafts, flanges, rings, and connector-type components.

- ● High-Rigidity Cast Iron Bed:Ensures exceptional vibration absorption and long-term dimensional stability.

- ● Turn-Mill Compound Efficiency:Reduces part transfer between machines and enables one-pass completion.

Recommended Configurations

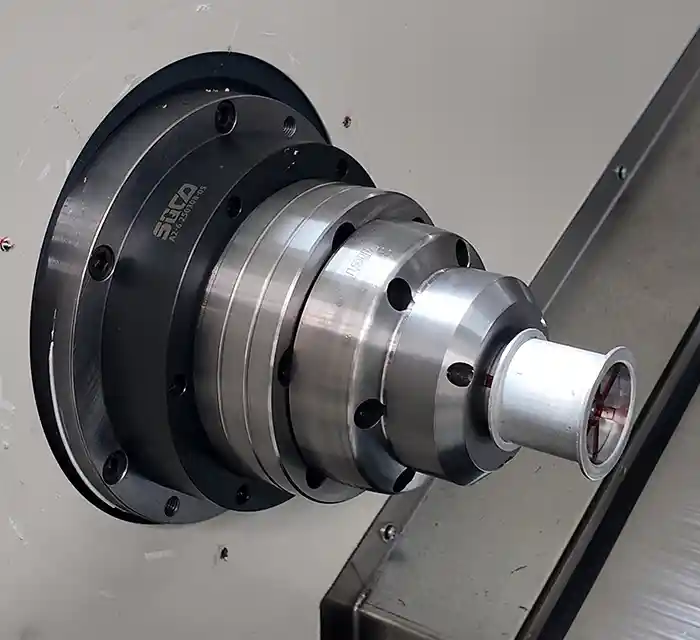

- ● Spindle Configuration: High-speed Electric Spindle, Dual Spindle System, Y-axis Powered Tool Turret

- ● Tooling System: Servo Tool Turret, Tool Compensation System

- ● Clamping System: Hydraulic Clamps, Pneumatic Clamps, Mechanical Clamps, Magnetic Clamps

- ● Feed and Drive System: Linear Drive, Ball Screws, Servo Motors

- ● Cooling and Lubrication System: Internal Cooling System, External Cooling System, High-pressure Cooling System

- ● Control System: High-performance CNC System (FANUC, Siemens, GSK, KND, SYNTEC, Mitsubishi, etc.)

- ● Other Configurations: Robot Arm, Renishaw OMP60 Workpiece Probe, Renishaw TS27R Tool Setting Probe, Chain-Type Chip Conveyor, Oil Mist Collector

Application Case

- ● Client: Precision Electronics Manufacturer – Netherlands

- ● Workpiece: Aluminum connector sleeve Ø24 × 50 mm for industrial control systems

- ● Setup: MNT25Y with 8-station live turret, Y-axis interpolation, FANUC controller

- ● Results: • Machining Strategy: Single-setup complete turning, side drilling, and grooving • Precision: Achieved dual-axis concentricity tolerance of ±0.004 mm • Surface Quality: Surface finish of Ra ≤ 0.8 μm with a final finishing cycle • Efficiency: Reduced cycle time by 38% compared to separate turning and milling operations • Surface Finish: Ra ≤ 0.8 μm achieved with finishing cycle • Cycle Time: Reduced by 38% compared to separate turn/mill processing

Product Specifications

| Specifications | unit | TCK50Y | TCK25Y |

|---|---|---|---|

| Max.swingdia.overbed | mm | 640 | 510 |

| Max.swingdia.overside | mm | 380 | 150 |

| Max.work piece length | mm | 400/700/1500 | 235 |

| Max.bar capacity | mm | 55/75 | 44 |

| Max.processng diameter(plate) | mm | 300/450/450 | 250 |

| Spindle nose | GB59001 | A2-6/8 | A2-5 |

| spindle bore | φ/mm | 66/86/86 | 56 |

| Spindle speed | r/min | 50-3000 | 50-4500 |

| Spindleshift mode | / | stepless speed control | stepless speed control |

| Spindle motor power | KW | 11/15/15 | 7.5/5.5 |

| Chucktype | / | Hydraulic chucks | Hydraulic chucks |

| Chucksize | lnch | 10 | 6 |

| Power turet model no | / | TCSDY80H-12T-330 | BW70-Y-35-BMT40-12T-4L |

| X-axis rapid traverse | m/min | 18 | 24 |

| Z-axis rapid traverse | m/min | 18 | 24 |

| X-axis servo motor torque | N.m | 15 | 10 |

| Z-axis servo motortorque | N.m | 15 | 10 |

| X-axis travel | mm | 240/260/260 | 135 |

| Y-axis travel | mm | ±45 | ±30 |

| Z-axis travel | mm | 500/800/1500 | 370 |

| Guide waytype | / | rails | rails |

| live tool holder | / | BMT45 | BMT40 |

| Tool shank size | mm | 25X25/032 | 20X20/025 |

| Tailstock type | / | Hydraulically | Hydraulically |

| Tailstock qulldia | φ/mm | 70/90 | 70/90 |

| Tailstock qulltravel | mm | 80 | 80 |

| Totalrated power | KW | 24 | 18 |

| Net weight | kg | 3400/4100/5100 | 2500 |

| Machine dimension(LxW×H) | (mm) | 2600/3370/4100×2000×2100 | 1810×1480×1940 |

Catalog

Frequently Asked Questions

Turning and Milling machine center can typically process various metals (such as aluminum alloys, steel, stainless steel, etc.), and some non-metallic materials. You can select a machine model that supports the specific materials you need.

For aluminum, it can reach Ra 0.8μm; for steel, Ra 1.6μm; for cast iron, Ra 3.2μm.

As a professional CNC lathe machine manufactor, Minnuo offers direct factory sales. We will provide the most suitable quotation according to customers' requirements to ensure the highest cost - performance ratio.

Minnuo has a strong and responsive pre - sales department. As long as you have the drawings, for a single piece of equipment, we can recommend the equipment within 10 minutes. For production lines composed of multiple pieces of equipment, we will provide a solution within 5 working days!

We have complete basic production equipment. For milling and turning machining,we customize components such asmachine systems, spindle speeds, motor power, and outer shell sheet metal.

Our company has several processing mother machines from international top - tier brands, which ensures the processing accuracy of cnc lathe machine components. Also, we provide a quality inspection report when the machine is dispatched from the factory.

For standard models, we keep stock and can deliver quickly. Custom models can be delivered within 30-45 working days.

Our mill and turn machine comes with a one-year warranty. During the warranty period, we provide free repair services. If the equipment malfunctions, customers can contact .

Need Help ?

Have any questions? For answers or additional information about ourmachines, please contact us here.

HOT Products

Our best-selling machine tools are designed to meet the needs of modern manufacturing.

WhatsApp(Tel):

Email:

Free Quote, Fast Response!

Fill out the inquiry form, and we will promptly provide a free, detailed quote. You can also reach us 24/7 via fax, email, or phone, or use our quick contact form to inquire about our services and projects.

Email

Email sales1: +86 13295238763

sales1: +86 13295238763